TechnologyJuly 14, 2021

Tips for getting Industrial IoT networks ready for the future

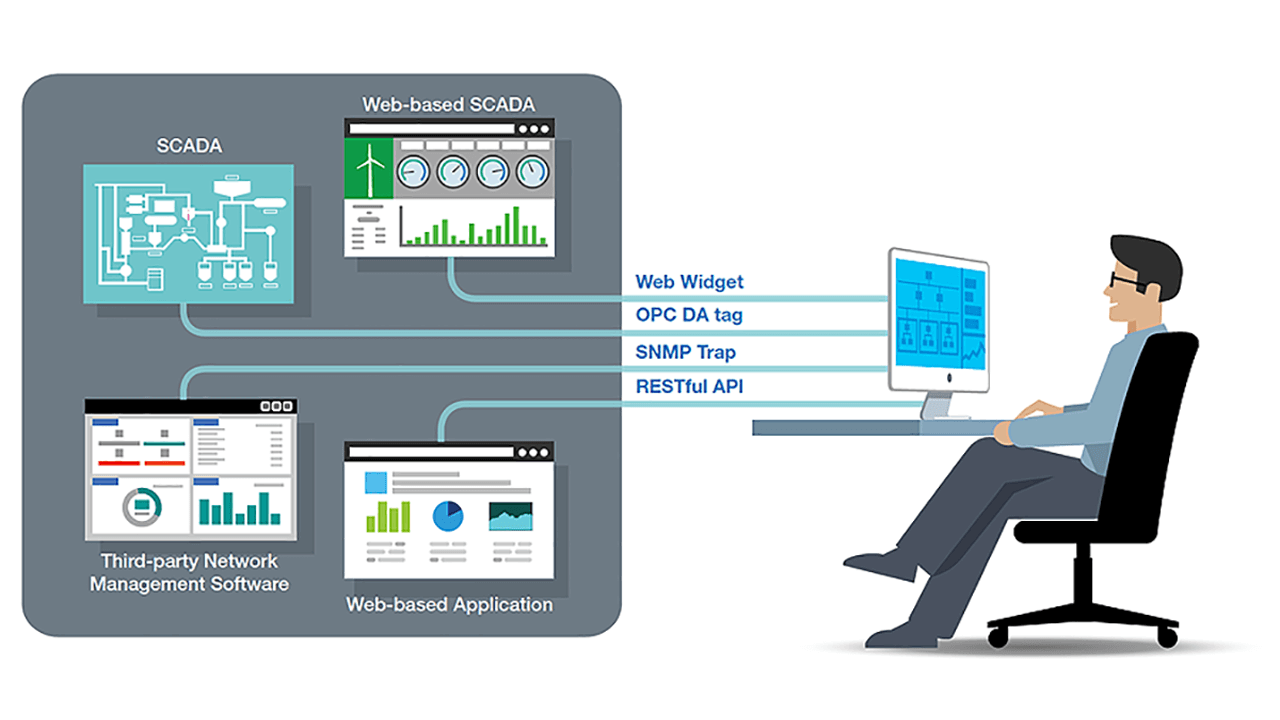

Managing industrial networks only in local control centers may not be feasible three or five years. It is therefore important to use network management software with integration interfaces such as OPC DA tags for SCADA system integration or RESTful APIs for external web services.

It may be a temptation to rest on your laurels when you finally have your IIoT networks up and running. Nonetheless, change remains the only real constant in life, and the world of industrial networking is no exception.

Your IIoT network may be sufficient for your current needs—it may even be ready for your foreseeable application requirements over the next several years. But what about the next decade or more? Change is always on the horizon, and we need to be prepared.

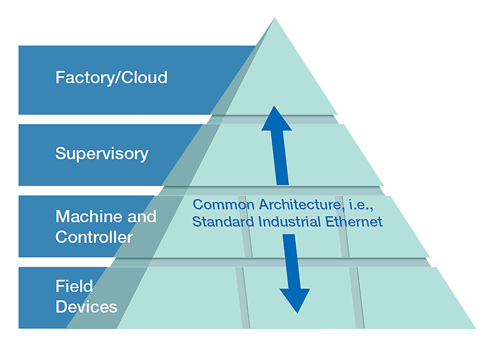

Since the early days of industrial automation, manufacturers have adopted a variety of purpose-built protocols and systems, instead of standard Ethernet technologies, for highly specialized industrial control applications.

However, as the IIoT market is expected to grow at a CAGR of 24% by 2023, industrial networks of the future will in all likelihood be required to transmit large amounts of data between interconnected devices or collect data from remote devices.

With these growing demands on the immediate horizon, how well-prepared is your company for the future of industrial networking may determine your success in tackling new challenges. This section provides three considerations to help you prepare your IIoT-ready industrial networks for the future.

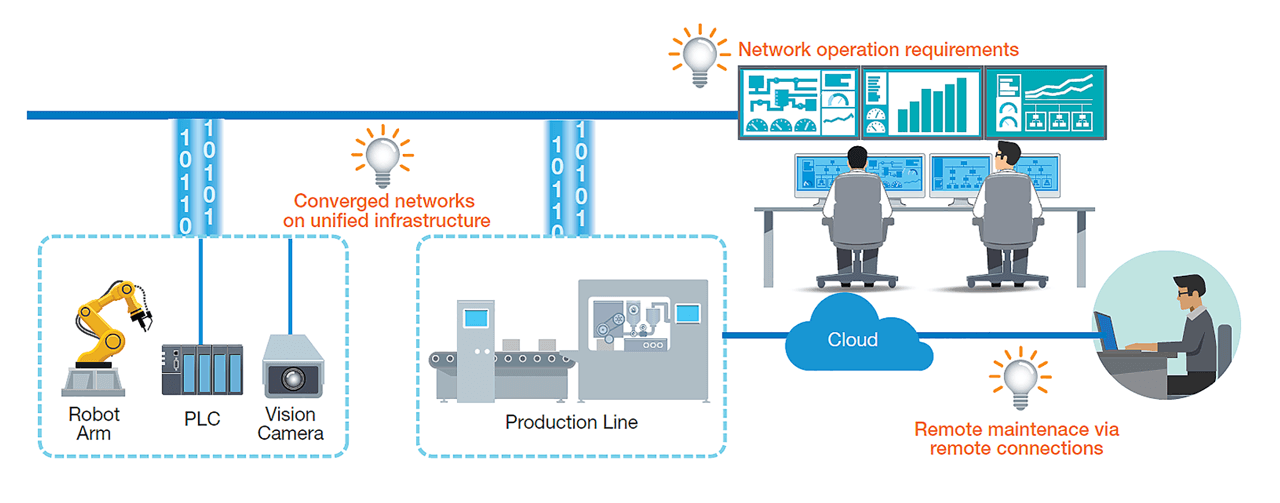

Achieve Greater Integration With Unified Infrastructure.

Access Anywhere to Your Remote Machines With Hassle-free Cloud Services.

Integrated unified infrastructure

Over the years, various devices using different industrial protocols have been deployed on industrial networks to provide diverse services. Under these circumstances, network integration usually costs more than expected or becomes more difficult to achieve.

Manufacturers can either choose the status quo, that is, maintain their preexisting isolated automation networks with numerous purpose-built protocols of the past, or alternatively they can seek solutions to provide deterministic services and integrate these “islands of automation”.

If our goal is to be ready for the growing demands on our IIoT network in the future, the choice is obviously the latter. The rule of thumb is to take potential industrial protocols into consideration and ensure you can redesign your networks in case any new demands arise in the market.

Time-sensitive networking (TSN) is a set of new standards introduced by the IEEE 802.1 TSN Task Group as an advanced tool box. With TSN, you can build open, unified networks with standard Ethernet technologies that reserve flexibility for the future.

Furthermore, you may consider selecting solutions offered by the key players who are advocating this new technology because they actively participate in TSN plugfests to complete the ecosystem and ensure compatibility among different vendors.

Hassle-free cloud services

Cloud-based remote access offers many benefits to IIoT customers, such as reducing the traveling time and expenses of sending maintenance engineers to multiple remote sites.

Furthermore, cloud-based secure remote access can provide flexible and scalable connections to meet the dynamic, changing requirements of the future.

However, operational technology (OT) engineers for water and wastewater treatment plants, machine builders, and other IIoT customers may find it cumbersome to set up and maintain their own cloud servers to provide new services and applications.

Indeed, considerable efforts are associated with setting up a new communication infrastructure, even if it is in the cloud. Fortunately, OEMs and machine builders can now deliver secure cloud-based services and remote access to their customers without having to maintain their own cloud servers.

One key issue to definitely scrutinize is the cloud server license scheme. Often, upfront costs may seem low for limited server hosts. However, these apparent cost savings on server hosts may actually make your project uneconomical due to a limited scale of connections.

Secondly, consider central management capabilities in order to flexibly expand remote connections in the future. With this said, carefully weigh the costs and benefits of incorporating secure remote access to your industrial networks. Always select solutions that can eliminate the hassles mentioned and help you focus on delivering more value and benefits to your customers.

Visualizing network status

You may have seen the following scene in a movie or photograph in the news. The control room of a metro system has a group of monitors showing the current status of each metro station in the system, the locations of all the moving trains, and so on. Managers or operators need to quickly judge the current situation and take action according to the information aggregated on the screens in front of them. This visibility helps them keep everything under control.

When complexity increases with greater connectivity on industrial networks, it can become very difficult to identify the root cause of problems and maintain sufficient network visibility. Control engineers often have to revert to trial and error to get the system back to normal, which is time-consuming and troublesome.

Therefore, in order to facilitate and manage growing industrial networks, network operators need an integrated network management software to make more informed decisions throughout network deployment, maintenance, and diagnostics. In addition, as your systems continue to grow, you will need to pay attention to a number of network integration concerns.

First, only managing industrial networks in local control centers may not be feasible three or five year later, especially when existing systems need to be integrated with new ones.

It is therefore important to use network management software with integration interfaces, such as OPC DA tags for SCADA system integration or RESTful APIs for external web services. Furthermore, an interface to facilitate third-party software integration is also a key criteria to ensuring future flexibility.

Application article by Moxa