TechnologyJanuary 23, 2025

TSN-empowered AI in automation

Users can implement automation applications more easily and cost-effectively with new AI tools. The rapid development of these AI tools, combined with a significant acceleration of hardware capabilities and integrated Ethernet interfaces, is opening up both new applications and segments.

Artificial intelligence (AI) has the potential to also be a game changer in automation. What role could Time-Sensitive Networks (TSN) play in making it easier and more cost-effective to leverage the possibilities of AI applications? What requirements does AI place on the networks of the future? What new applications and solutions can be implemented by TSN? And what does the path to this look like?

Detailed information about TSN is already widely available. This article will therefore look at application examples with an AI focus that can benefit from TSN. The focus here is not on motion control, but on other applications with great benefits for the technology. Some of the examples included should encourage us to explore options beyond the limits of what is currently available.

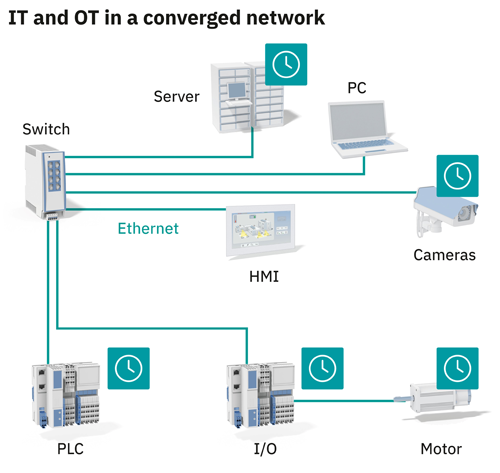

Figure 2: The convergent network for IT and fieldbus as the basis for AI .

The rapid development of AI tools, combined with a significant acceleration of hardware capabilities and integrated Ethernet interfaces, is opening up new applications and segments. They generally have the following requirements:

- Large amounts of data have to be transported from the field to the AI system.

- The forwarded data must be provided with highly accurate time stamps so that, for example, a time series data analysis can be carried out by means of comprehensive correlation.

- It must be possible for the result of AI processing to feed back into the field.

These requirements cannot be fully or sufficiently met with conventional industrial Ethernet based on 100 Mbit technology. This is where the possibilities of Time-Sensitive Networking come into play. The following examples are intended to illustrate which applications with an AI focus can be implemented or improved by a convergent TSN network.

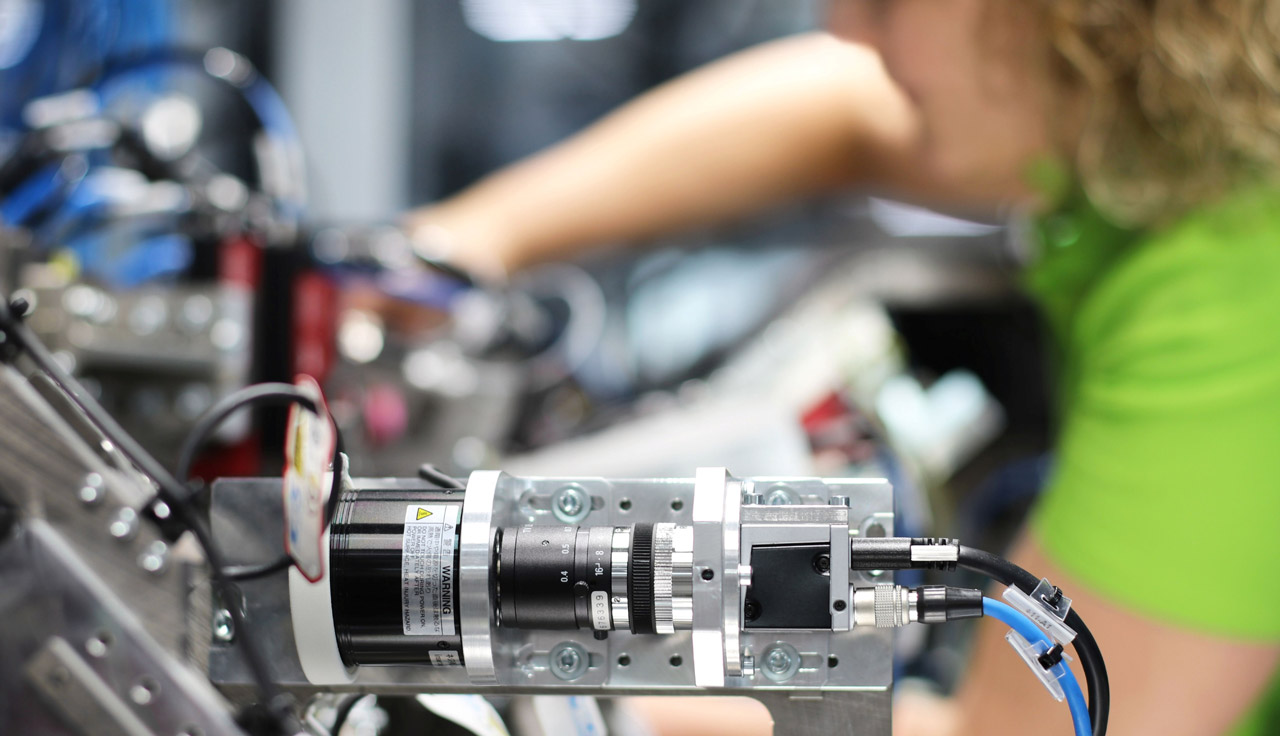

Figure 3: Camera-based quality control in Phoenix Contact production.

Camera-based quality control in the active process

In a production machine or production line, special industrial cameras (GigE Vision) are used to take pictures of the active process or of products. A machine learning mechanism trained on the basis of the good parts detects quality defects and controls the production process accordingly. Current image processing hardware performs such evaluations in a matter of milliseconds. This makes it possible to carry out quality control during the active production process.

Multiple cameras can also be synchronized to take pictures of a workpiece at exactly the same time. This then allows for 3D calculations or time series analyses, for example. It is no longer necessary to separate the camera and control networks. Since the evaluation algorithm runs on external hardware, it can be flexibly adapted to different products and conditions. Industrial vision applications require a lot of bandwidth. Depending on the resolution and refresh rate, the value quickly adds up to several 100 Mbps. In addition, jumbo frames are used in vision applications, which particularly benefit from the TSN mechanism preemption. For this reason, convergent networks are currently the exception rather than the rule in vision applications, but this could change with TSN.

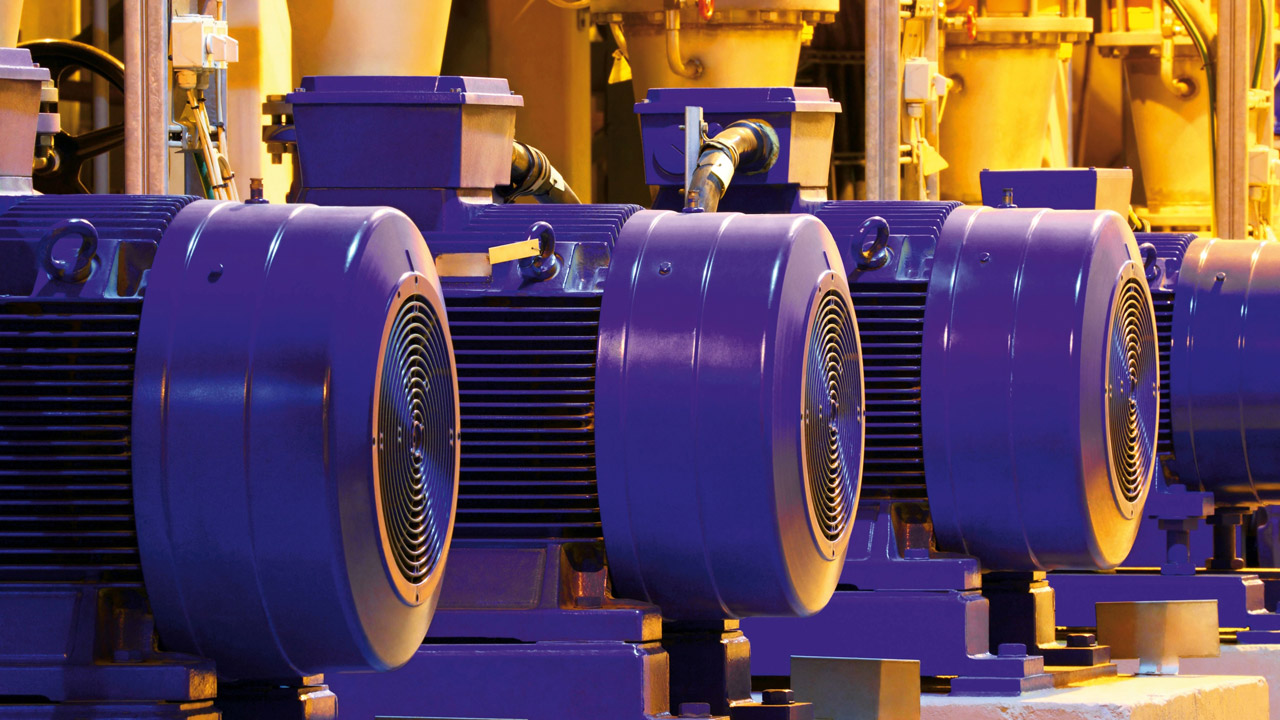

Figure 4: Preventive maintenance of large motors using AI.

Preventive maintenance of large machines

Use in the field of predictive maintenance is illustrated using the example of large drives. Sensors in or on the motor measure temperature and vibration data. A power measuring device also determines the respective energy requirements of the motor. This trains an AI model for normal operation of the motor based on this data. The exact temporal correlation of energy, temperature, and vibration data is also helpful here.

If several drives are operating in a process, it is also necessary to have a system-wide understanding of time. If any operating parameter deviates from the normal state – for example, due to bearing damage, other wear, or problems in the process – the operator can respond ahead of failure during the next scheduled maintenance, or the process can be controlled differently. The small amount of effort required to train the model is more than offset by the benefits of predictive maintenance.

Figure 4: Preventive maintenance of large motors using AI.

Synchronized feed-in of renewable energy

The energy transition is creating a new and largely unknown problem. Power stations for primary energy sources such as coal, gas, and nuclear power operate generators with large rotating masses.

The kinetic energy stored in these masses helps the power grid cope with load fluctuations and provides the reference frequency for alternative generators, such as wind turbines or solar parks. With more and more conventional power stations being replaced by alternative generators, this grid-supporting effect is lost.

For example, it is not readily possible to ramp up a wind farm without an external grid in stand-alone operation. One solution to this problem is the highly accurate synchronization of all generators and their electronic feed-in converters with a corresponding setpoint definition. This can be done by TSN over the network that is already required for operating data. Installing two separate networks in a wind farm covering several square kilometers would be a major cost factor.

Root cause analysis of events

Another field of application is the temporal and localized analysis of events that occur during system operation. These are required by insurance companies in the event of a malfunction in order to be able to carry out a root cause evaluation. If this is primarily handled in the controller at present, this may no longer be sufficient in the future, because not all of the relevant data, such as the above-mentioned data from the motor, is available in the PLC.

Due to the time synchronization, TSN makes it possible to record events with highly accurate time stamps of less than 1 ms in the devices themselves.

The convergent network also ensures the simultaneous transmission of events to an analyzing unit, which does not have to be the controller (and may not be if a controller itself is the root cause). AI makes it easy to search through the vast amounts of messages for anomalies. The high accuracy of the time stamps supports this. In addition to a root cause evaluation, hidden problems are also found and rectified during operation.

Implementation is already possible

In addition to the examples shown above, there are numerous other applications that can be implemented by using AI in automation. Many of these examples cannot be realized without convergent TSN networks and time synchronization or are otherwise significantly more complicated and expensive to implement. In these applications, TSN mechanisms can play to their strengths in the network compared to specialized real-time bus systems.

Perhaps the greatest benefit of TSN lies in these applications rather than in replacing current special bus systems for motion control. Another piece of good news is that it is already possible to implement the applications described. The switches from Phoenix Contact currently support functions such as Quality of Service (QoS), Precision Time Protocol (PTP), and preemption. The GigE Vision standard also specifies the use of PTP. AI combined with TSN will therefore enable a new generation of automation applications, and their development is probably just beginning.

Advantages of TSN at a glance

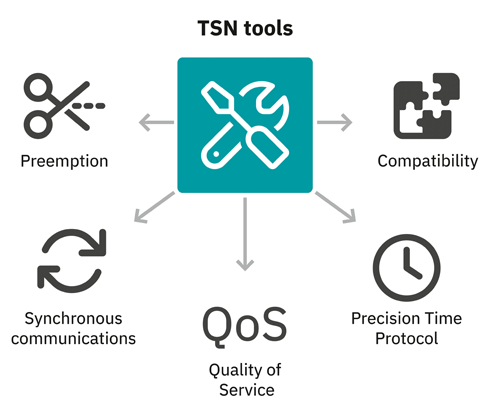

Figure 6: The TSN tool box.

Time-Sensitive Networks are not a single standard. Rather, TSN can be compared to a tool box containing several tools, each of which serves a specific purpose:

Quality of Service (QoS in accordance with IEEE 802.1Q) enables the use of a common network for time-critical process data and large amounts of data, such as camera images. A bandwidth of 1 Gbps or more is essential here.

Precision Time Protocol (PTP in accordance with 802.1AS) provides time synchronization with under 1 μs accuracy, even in larger network topologies. The widely used Network Time Protocol (NTP) is not capable of this, but it can be used together with PTP in the same network.

Preemption (802.3Qbu, 802.3) solves the problem of interference between time-critical real-time data and non-time-critical data, such as jumbo frames from camera systems. This means that real-time transmission is not delayed by large, non-critical telegrams.

Synchronous communication based on PTP allows the transmitters to be synchronized in order to reduce jitter. The function is not always necessary in many applications that currently work with PROFINET RT, for example.

Special QoS mechanisms allow the existing device landscape to be seamlessly integrated into TSN networks. This enables gradual implementation in applications that will yield the greatest benefit.

All of these tools and the way they interact form the convergent network, in which IT data and critical process data as well as highly accurate time synchronization coexist. This significantly reduces the costs and complexity compared to special networks for these disciplines.