TechnologySeptember 20, 2021

Digital twins create the perfect match

In the words of the Greek philosopher, Aristotle: "The whole is greater than the sum of its parts." Although this conclusion was made long before Industry 4.0 and the Smart Factory even came to be, it hits the nail on the head when it comes to machine manufacturing.

Combining hardware, software and programming code does not automatically produce a functional machine. Only the perfect interaction of these combined “parts” will result in a functioning “whole”. Simulation plays a key role in achieving this.

What role does simulation play in machine manufacturing and plant engineering? “The answer is simple”, said B&R’s product manager for simulation, Isabella Laasch. “It is the key to the next level of efficiency throughout every phase of a machine’s lifecycle.”

Machines are becoming more and more complex. This also means that the interplay between mechanics, electrical equipment and automation is becoming increasingly difficult. Testing possible machine sequences directly on a physical system incurs high costs and is all-around inefficient. This applies to each phase of the machine’s life: development, commissioning and ongoing operation.

Costly, time consuming design flaws

Even in the first phase of its lifecycle, the machine goes through multiple stages. Major defects can occur in any of them. The Rule of Ten states that the cost of correcting a defect increases by a factor of 10 for each stage of machine development at which the defect was not detected. Correcting the defect as soon as possible will therefore speed up the development process and save costs.

If defects occur throughout the entire development process, however, they won’t be detected until the commissioning stage. “If one problem after another arises while the machine is being commissioned, the outcome will be disastrous,” says Laasch.

Not only have they already gone to the expense of producing a prototype, the development team is now occupied with finding and resolving the source of the problems.

If the hardware is damaged, there will be additional expenses for spare parts as well as a possible delay due to long delivery times. In the worst case scenario, the machine builder may even be subject to contractual penalties if the new machine cannot be delivered to the customer on time.

Simulation is the key

“Essentially, we have to find a way to digitally map a machine during each phase of its lifecycle,” said Laasch. “The way I see it, there is only one way to do this and that is with simulation.” A digital twin of the machine is created in the virtual simulation environment. With the help of the digital twin, the interaction of the individual components can be checked during development and the machine can be commissioned virtually.

According to Philipp Wallner, Industry Manager at MathWorks, “With model-based development, it is possible to ensure that the machine will work at an early stage, thereby reducing the risk of failure to a minimum. Simulation models form the basis for the design phase, virtual commissioning and digital twins. An investment in simulation will usually pay for itself within the first year.”

Cooperation with simulation experts

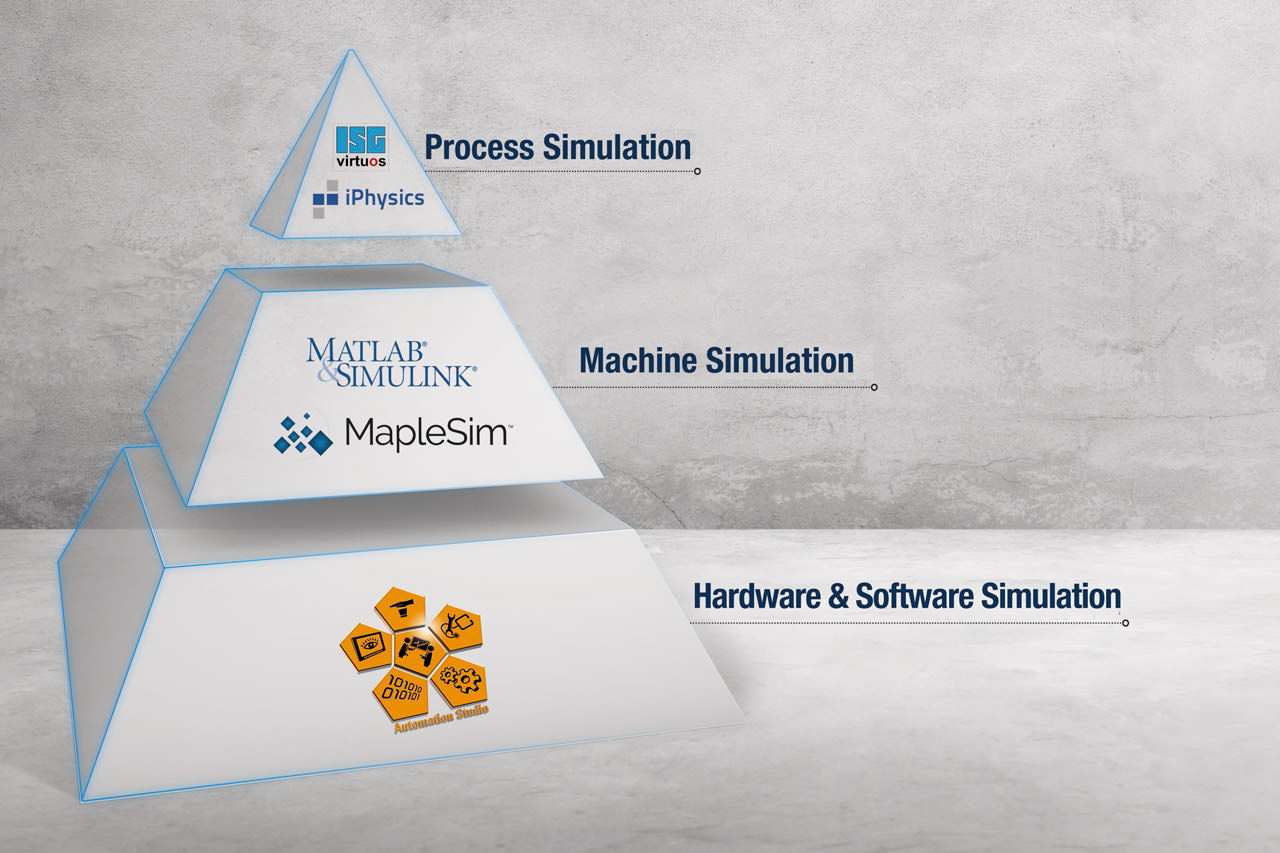

Machine builders can choose from a wide variety of simulation tools. The offer ranges from tools for hardware and machine simulation to process simulation. For this reason, B&R has dedicated many years to working together with various simulation experts and integrating different tools into its automation system.

“In cooperation with our partners such as MathWorks, Maplesoft, machineering and ISG, we offer a wide range of simulation options and have the right solution for each application. “The decisive factor here is that our customers are free to choose which simulation tool is best suited for their machine. The B&R development environment is the central tool in every case.”

The right tool for any requirement

The simulation software from Maplesoft and MathWorks can efficiently and accurately map machine components, for example, and momentum and forces can be simulated for machine designs. Here, it will be easy to test various load cases. Testing on a real system would require many working hours and numerous resources. An oversized load could result in damage to valuable hardware that will then need to be replaced. With simulation, however, the machine builder can see at a glance whether or not the machine can handle a given load.

“When machine builders face performance issues, they need a quick fix that doesn’t eat away at their profit margins. Dynamic, physics-based digital twins allow machine builders to detect problems in their designs and figure out how to solve these problems without additional hardware costs,” said Chris Harduwar, VP of Business Development at Maplesoft.

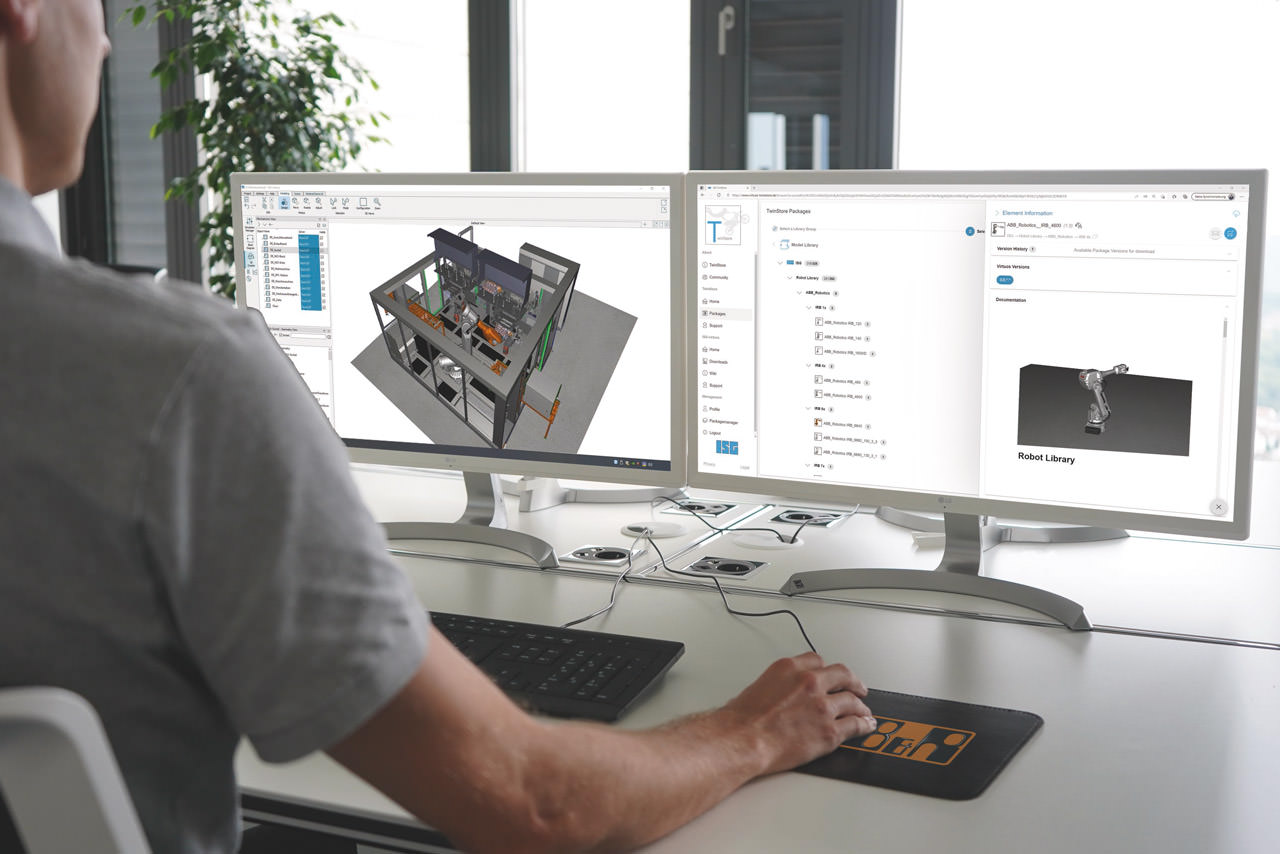

The tools from machineering and ISG, on the other hand, cover the area of process simulation. They show the dynamic behavior of a complete machine in 3D. This allows all dynamic factors that affect the material flow to be tested in real time with the digital twin. The machine builder gets instant visual feedback about how behavior is affected by different combinations of machine components. Unnecessary downtime can also be identified and eliminated at an early stage.

Unplanned downtime has a steep cost for manufacturers and is a priority for Industry 4.0 technologies.

Using data for predictive maintenance

Even after the machine has been developed and deployed, the digital twin is not done adding value. The digital twin continues to run in the control cabinet as a virtual copy of the machine, using real-time operating data to make accurate forecasts about the health and remaining service life of the machine’s components.

“If the behavior of the real machine deviates from that of the digital twin, because of a worn out bearing, for example, the difference is detected immediately”, Laasch explained.

The collected data is used for predictive maintenance, fault documentation, remote maintenance systems, etc.

Dr. Georg Wünsch, Managing Director, machineering GmbH & Co. KG added that “our iPhysics simulation software provides consistency in engineering. It combines all disciplines ranging from MCAD, ECAD and automation to production and after sales service. With the additional connection of AR and VR systems, complex mechatronic machines are completely secured at all times.”

Reduced training time

The digital machine counterpart also opens up new possibilities for training machine operators and service technicians. Theoretically, they can learn how to work with the Human Machine Interface or the machine itself before it actually arrives on site. This significantly reduces the time required for training new operators.

The digital twin is also increasingly being used in virtual showrooms, which allows the sales department to present new machines to potential customers at any time, even outside of trade fairs or events. With the help of augmented reality headsets, the digital machine can even be superimposed in realistic environments. This makes it possible to test what-if scenarios when planning and developing machines with moving objects.

Dr. Christian Daniel, Business Manager for Simulation Technology, ISG Industrielle Steuerungstechnik GmbH said that “if you configure simulation scenarios as digital twins with virtual reusable components from a library, then they can also be used by the plant operator for production optimizations, retrofits and as a basis for innovative training and service concepts.”

Simulation tools like machineering’s iPhysics offer effective process simulation and show the dynamic behavior of a complete machine in 3D.

Faster machine development

“The digital twin accompanies a machine through each stage of its lifecycle,” says Laasch. “Furthermore, it forms the basis for new functions and future improvements to the machine.” The machine builder can use insight gained during operation to optimize the system, for example. The simulation model can then be used to test the planned modifications. This reduces the downtime for upgrades to a minimum and speeds up the development process for the next generation of machines.

“In cooperation with our partners such as MathWorks, Maplesoft, machineering and ISG, we offer a wide range of simulation options and have the right solution for each application. Our customers are free to choose which simulation tool is best suited for their machine. The B&R development environment is the central tool in every case,” Laasch added.