TechnologyJanuary 23, 2022

Industrial Internet of Things 2022 Progress Report

Industry experts provide their perspective on the state of the Industrial Internet of Things. Our 2022 progress report explores how IoT technology is being implemented into complex industrial environments as part of digital transformation strategies, and leverage a wide range of connectivity solutions.

Industrial Internet of Things (IIoT) technology is driving a wide range of new networking solutions, from the sensor to the cloud, that are enabling new levels of digital innovation with a goal of transforming global manufacturing.

For the 2022 IIoT progress report, IEB reached out to industry experts to get their insights into the development of the Industrial Internet of Things and perspectives on the megatrends shaping and enabling development of the IIoT. Key technologies include the emergence of Single Pair Ethernet and Ethernet-APL, software connectivity trends provided by OPC UA and MQTT, and new options for leveraging solutions for wireless systems and machine learning.

But experts also note that all the technology needed is available, and it’s more a matter of adoption. We’re just starting to understand how to make IIoT happen in a way that is simple and affordable for most businesses.

SPE, OPC UA and MQTT

Connectivity solutions drive innovation

According to Dr. Al Beydoun, President and Executive Director at ODVA, the leading megatrends driving the IIoT forward include the emergence of two-wire Ethernet connection technologies, OPC UA for information applications and the use of MQTT to create cloud connectivity.

Technology megatrends

MQTT is a basic option to push data from existing automation networks such as EtherNet/IP to the cloud.

“ODVA supports Internet Protocol (IP) to the industrial edge by advancing 2-wire Ethernet technology such as Ethernet Advanced Physical Layer (Ethernet-APL) and Single Pair Ethernet (SPE). Multi-stack IIoT devices have the ability to support EtherNet/IP to real-time controllers, OPC UA to on-premise IIoT information applications, and MQTT to cloud IIoT applications,” Beydoun told IEB recently.

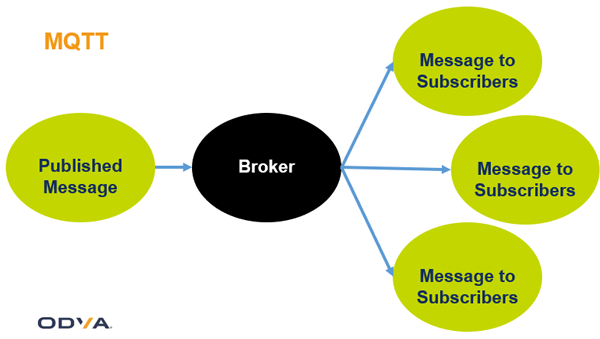

“MQTT is a lightweight publish/subscribe network protocol that is an option to transport data from automation devices, including those running on EtherNet/IPTM, to the cloud. Minimal network bandwidth is required making MQTT a scalable method to connect existing devices to the internet at a low cost. MQTT adoption has been gaining momentum across automation, but in particular in industries such as automotive and oil & gas,” Beydoun said.

He added that prognostics is a critical IIoT trend that will change the way that maintenance is approached and what expectations are regarding production down time.

“The ability to monitor for excessive vibrations and sounds or to look for out of tolerance changes such as media pressures, motion travel times, or electrical resistance levels can provide early warnings of device degradation. This can allow for time to order and replace faulty components, including an extra buffer in case of part number mistakes, training, or delays. Not only can unplanned plant shut downs be reduced, but unneeded preventative maintenance can also be minimized,” he added.

Potential benefits

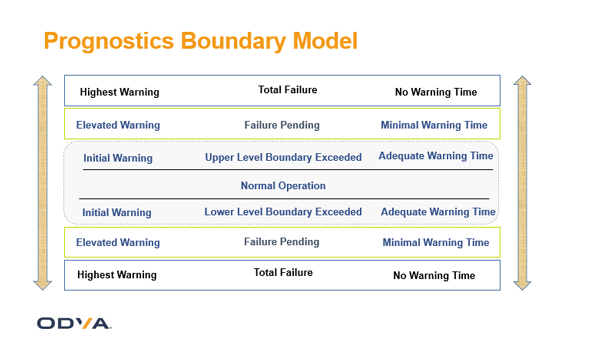

Prognostics boundary model.

Beydoun said that MQTT is a basic option to push data from existing automation networks such as EtherNet/IP to the cloud. Messages can be published from devices to a broker and then sent to subscribers. The presence of a broker allows for some additional security mechanisms to be put in place, although basic security principles would still apply regardless. The lightweight nature of the protocol also means that existing networks won’t be overly taxed by pushing valuable diagnostics data up to the cloud via TCP/IP.

With prognostics, device manufacturers can embed capabilities into the firmware of their devices and can leverage their engineering expertise to provide pre-determined engineering boundaries that indicate normal operation as well as indications of pending failure.

These pending failure warnings could provide specific timelines to allow for proper scheduling of maintenance and replacement. For example, if resistance on a coil exceeds +/-10% of specification an initial warning with the longest timeline of action needed can appear, with escalations as further degradation takes place.

Remote connections to these devices can allow for updating of parameters if needed and for monitoring of device health over time.

Addressing challenges

“Leveraging MQTT gateways to connect to existing automation networks with large installed bases, like EtherNet/IP, can reduce the amount of labor time required to move data to the cloud to create new prognostic, health, or operational tracking metrics,” Beydoun said. “This approach is scalable, allows data value from existing devices to be unlocked at a reasonable cost, and allows for easier future changes and expansions versus ad hoc approaches. The low cost and lightweight advantage of MQTT can also be a disadvantage as data context is not inherently included and must be added as a separate step.”

From a prognostics perspective, embedding capabilities into devices and even networks can reduce the burden on controls engineers to create custom PLC programming or data scientists to develop cloud-based algorithms to look for out of tolerance device or machine behavior.

Automation engineers and maintenance personnel work tirelessly to keep plants and factories operating at the best efficiency with the most uptime, but are oftentimes put in challenging positions of trying to solve device issues in the middle of the night and/or on the weekend. It’s sometimes difficult or even impossible to connect with the appropriate manufacturer support resources outside of regular business hours. Built in prognostics directly from manufacturers allows for their valuable expertise to directly benefit controls engineers and maintenance personnel when they need it the most.

IIoT progress and impact

“IIoT has been moving faster than most technological shifts within the automation space, especially with the recent challenges and opportunities posed by the pandemic,” Beydoun said. “Cost is a significant constraint as existing capital investments must be leveraged and return on investment must be proven on a small scale before wide spread implementations take place.”

Additionally, worker education takes time to roll out as does acceptance of new ways of doing things. This extra time isn’t all bad as some technologies that were initially leveraged for IIoT solutions have been shown to be inadequate for the long term due to issues such as security and scalability.

The additional time to pilot and prove out technologies has also allowed for the best long-term solutions to win out and for improvements to be made to those solutions during pilot phases. CIP SecurityTM is an example of a critical underpinning of IIoT that has seen significant development over the past few years with the most recent additions of user level authentication and resource-constrained device support.

“Overall, there has been a tremendous amount of progress within the automation space as a result of IIoT. 4G and now 5G machine connections to support providers have allowed for service to take place remotely, wireless connections to devices have allowed for additional operational functionality as well as easier troubleshooting and parameterization, and cloud-based analysis has allowed for preventative maintenance to reduce downtime in critical operations,” he added.

Development of IIoT applications

CIP Security is a key technology that Beydoun says will ensure the security of critical automation applications as IIoT development intensifies. CIP Security allows for different security profiles to be applied to a device as a part of a defense in depth approach to allow for a balance between security and resource needs.

EtherNet/IP devices enabled with CIP Security can reject data that has been altered (integrity), reject messages sent by untrusted people or untrusted devices (authenticity), and reject messages that request actions that are not allowed (authorization).

He added that ODVA is also collaborating with the OPC Foundation to develop an OPC UA Companion Specification for CIP. This will allow valuable factory floor information from EtherNet/IP to be made available at the edge and the cloud via OPC UA for enterprise-wide analysis.

Sending data to and from the cloud from EtherNet/IP to OPC UA will be accomplished by providing useful information including discovery, identity, diagnostics, status, parameter and much more from CIP devices. The OPC UA companion specification to CIP will ensure that data will be available to enterprise and IT systems with proper context and semantics (i.e., meaning) for quick trend analysis and insight generation.

Open source solutions

Collaboration and compatibility as priorities

Josh Eastburn, Director of Technical Marketing at Opto 22 told IEB that new open source software technologies and initiatives are making on impact on the IIoT, and provide a way to deal with technical issues such as scalability and connection security.

Technology megatrends

Eastburn said that the Eclipse Sparkplug working group has made strides over the last two years in gathering contributors to the open-source projects pushing towards the release of a formal Sparkplug specification.

In 2022, we’re looking forward to seeing the fruits of all that collaboration. A formal specification of the Sparkplug payload definition for MQTT, along with testing tools to help vendors verify compatibility with the specification, will strengthen guarantees of interoperability and increase adoption.

The MQTT/Sparkplug B architecture defines clear roles and behaviors for MQTT clients and their data, adapting the underlying MQTT framework to better support typical SCADA/IIoT use cases.

Potential benefits

“MQTT solves the problem of scalability and connection security for IoT applications. However, it doesn’t address interoperability and provides only limited client state awareness. It can work for industrial applications, but these limitations challenge wider adoption,” Eastburn said.

“Sparkplug enhances MQTT for industrial applications by defining interoperable formats for MQTT topic paths and payloads as well as additional state awareness mechanisms. Together, these features enable auto-discovery of MQTT data, interoperable data exchange across domains, as well as the representation of more complex data types, metadata, and asset models,” he added.

Automation challenges

Eastburn noted that most IIoT applications today still rely on point-to-point connections between software and hardware, like PLCs and sensors.

Infrastructure based on REST/HTTP or traditional industrial protocols is costly to scale up and produces data that may require additional translation and enrichment before it provides useful information. Security may be non-existent, requiring extraordinary measures in order to safely integrate IT and OT networks.

Sparkplug simplifies data infrastructure, using MQTT as a foundational technology. Engineers can build systems that communicate securely among millions of clients while consuming 80 – 90% less bandwidth than traditional protocols, and Sparkplug reduces tedious tasks like tag mapping and client configuration because most of these details are abstracted away.

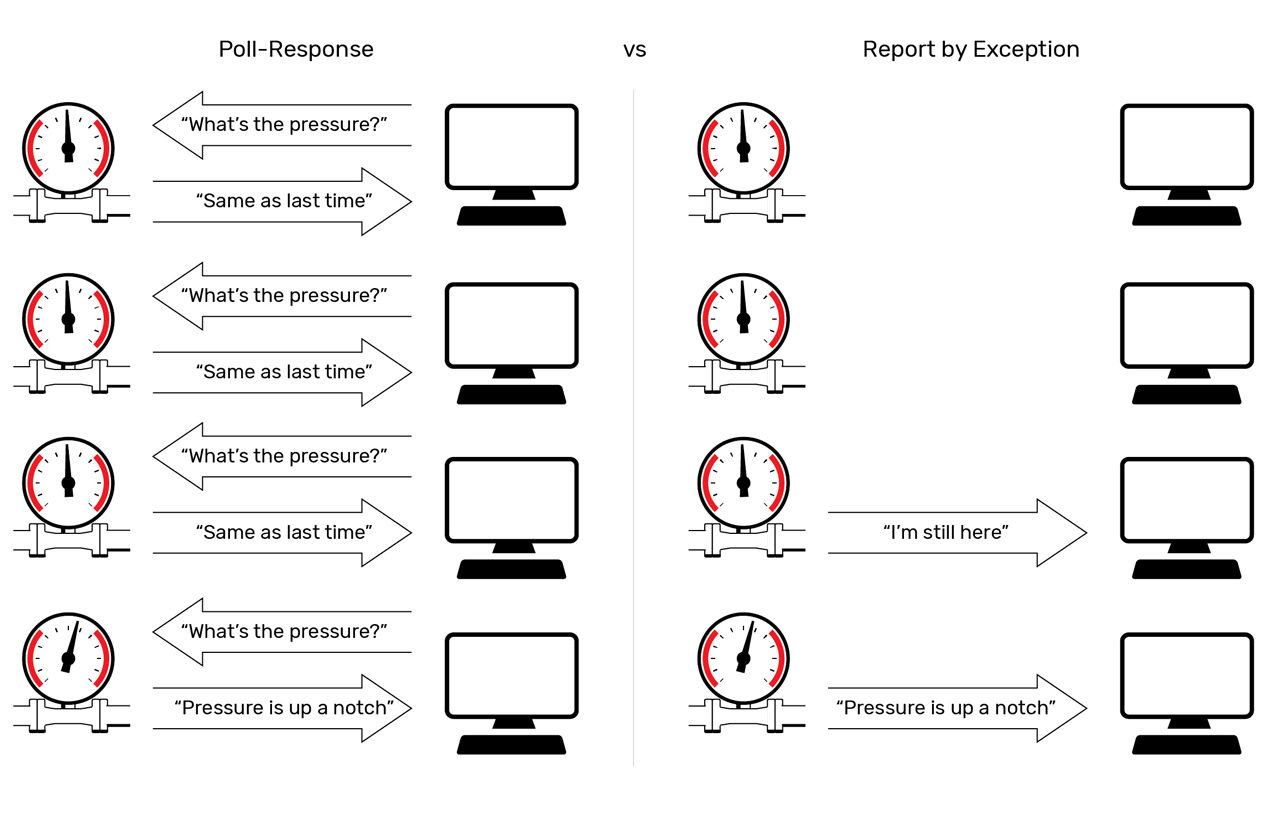

Poll-response protocols generate a lot more network traffic than report-by-exception.

Progress and IIoT impact

“Smart devices were only the beginning of the solution. For industry, the bigger concern is the long-term cost of ownership, which has kept it from being a realistic vision for all but the largest organizations,” Eastburn added. “We’re just starting to understand out how to make IIoT happen in a way that is simple and affordable for most businesses. It turns out that doesn’t necessarily require ubiquitous smart devices. In fact, there is more interest in extracting useful data from all the dumb devices we already have. With broader Sparkplug adoption, we’ll be able to do that quickly, affordably, and repeatably.”

Development of IIoT applications

He said that cybersecurity is a top concern inhibiting IIoT development that cannot be fully addressed by application-level solutions like Sparkplug.

“We need to see more hardware vendors taking on the challenge of providing IT-compliant networking and security technologies in automation devices if IIoT is really going to take off,” he concluded.

“It’s a matter of adoption”

Technology offers new possibilities.

Brian Taylor, business director, Safety, Sensing and Connectivity at Rockwell Automation told IEB that wireless communications, machine learning and providing key technologies but also that all of the technology needed is available. Development of IIoT applications is more an issue of adoption.

More companies are using data to detect problems sooner and increase productivity.

Technology megatrends

“There’s a lot of growth potential for wireless in production environments. It’s still largely underutilized, more so in manufacturing operations than in remote industrial operations,” Taylor said. “One reason wireless hasn’t taken hold yet in manufacturing is because people go with what they know. And in manufacturing, people are simply more comfortable and familiar with using wired communications.”

“Still, it’s important to understand the benefits of using wireless. Specifically, it can deliver cost savings over wired communications and provide easier access to IIoT data, which is the lifeblood of digital transformation initiatives. We could see wireless usage grow soon given the large number of brownfield facilities that need to be updated,” he added.

Taylor said that machine learning is another technology that will continue to take hold and transform industrial operations in 2022.

There’s been a strong focus on artificial intelligence (AI) applications in the industrial world in recent years. Machine learning applications and deployments are still only in their infancy. So far, it’s mostly startups and early adopters that are embracing the technology. But that’s likely to change soon. Because there’s tremendous potential in using learning algorithms to understand the performance of machines and help them perform better.

Potential benefits

“Wireless communications are ideal for sensors and other data-producing devices that can help companies track the health and performance of their production assets. Wiring sensors can be a costly and time-consuming process for existing equipment. Wireless options are more cost effective,” Taylor said.

More importantly, he noted that smart wireless sensors can provide access to data that – once cleaned and contextualized – can help companies operate more efficiently and with less unplanned downtime. By tracking the parameters that are important to them – whether it’s motor temperature, vibration and voltage, or the speed of a belt – companies can identify issues early and potentially take corrective action before failures occur.

In remote operations, wireless can play an even bigger role. In mining, for example, it can help with remotely connecting and locating people, deploying autonomous transportation, and running ventilation-on-demand systems.

Machine learning can help companies take the performance of their machines or equipment to another level. Today, companies may have access to the raw data from these assets, but they may not have deep expertise in data science and industrial processes to turn the data into useful insights. Solutions like add-on modules for industrial controllers can use machine learning to predict anomalies or estimate operational variables. This can help drive improvements in throughput, product quality, process integrity and more.

IIoT adoption has a steep learning curve and requires companies to develop new skillsets.

Automation challenges

“Once implemented, wireless communications can help automation and control engineers identify issues earlier and take corrective action before failures occur, often resulting in less unplanned downtime,” Taylor added. “That said, installing and troubleshooting wireless often requires other skillsets like IT. Understanding what to do with all the data also requires other skillsets like computer science. So, before wireless addresses challenges for control engineers, they will likely need to consult and collaborate with others.”

His perspective is that machine learning will help engineers more easily and quickly identify and diagnose machine issues. Especially after a machine learns over time, it should significantly reduce the amount of time engineers spend walking around a factory floor diagnosing issues.

IIoT progress and overall impact

Taylor said there was strong interest in the IIoT early on. And certainly there were trailblazers who led the way and helped us get where we are today, with 9 in 10 manufacturers now saying digital transformation is important to their success.

“There’s no denying, however, that IIoT adoption has been slow and steady. It has a steep learning curve and requires companies to develop new skillsets. It requires new investments, although those investments can start small. And many companies have simply held off investing until the use cases and value of IIoT technologies were well established, which they clearly have been,” he said.

“Today, we’re at a turning point. Companies are realizing that digital transformation is vital to staying competitive. Their resiliency has been tested by the pandemic, supply chain disruptions and a global skills shortage. Now, they’re turning to automation and digitalization to remain productive and profitable amid these challenges,” he added.

More companies are using data to detect problems sooner and increase productivity. Smart sensors on conveyor belts, for instance, can reveal areas of contamination. Smart sensors can also provide early warning of issues like bearing failures. Even safety data can play a role by providing a detailed picture of where, when, and why safety-related downtime is occurring.

Development of IIoT applications

“All the technology needed is available. At this point, it’s a matter of adoption,” Taylor concluded.

The skills shortage is a major factor that’s driving adoption today. U.S. manufacturers cite an inability to increase revenue growth as the top consequence of not being able to fill jobs. Now, companies are using IIoT technologies in a wide range of ways to help mitigate this challenge.

They’re closing knowledge gaps and creating more connected workforces. They’re using smarter devices that leverage AI and machine learning. They’re using smart devices to enable preventative maintenance.

When implementing new technologies or techniques, like wireless communications, industrial professionals can learn a lot just by looking to their own homes. They can keep the control systems in their plants wired just like they’d keep the alarm system and smoke detectors in their home wired. But smart sensors aren’t essential to uptime, so they don’t need to be wired. Just like how smart TV remotes, lights or doorbells probably won’t threaten your safety if their battery dies.

“All of that said, adopting IIoT technologies right now can be more difficult due to the instability in global supply chains during this pandemic. As supply chains are stabilized, companies will be more able to prioritize developing IIoT applications to address issues and provide business value,” Taylor said.