TechnologyFebruary 2, 2021

Industrial Internet of Things 2021 Progress Report

A broad set of IIoT-enabling technologies from Industrial 5G to OPC UA, cloud and edge computing, Time Sensitive Networking and Single Pair Ethernet, to name just a few, are continuing to emerge and will empower and drive new levels of innovation for companies implementing IIoT applications.

New Industrial Internet of Things technologies are creating a richer and richer ecosystem of connected devices, controllers and subsystems, from the sensor to the cloud, enabling new levels of digital innovation that is rippling through and transforming global manufacturing.

The rate of change may not always seem to be profound, but when you stack all of the significant areas of technological change related to the IIoT together, we see a different picture.

Major initiatives including development of Industrial 5G, Edge Computing, IT/OT Convergence, Time Sensitive Networking, Single Pair Ethernet, Cybersecurity Standards and OPC UA provide an impressive array of developing new possibilities that will drive the IIoT forward for the foreseeable future.

Even though we already have a decade of IIoT development in the books, in many respects we are still early in the process and the best is yet to come.

IIoT progress report

For this IIoT progress report, IEB reached out to major players in the development of the Industrial Internet of Things to get their perspective on the megatrends shaping and enabling development of the IIoT in 2021 and beyond. We wanted to know what specific benefits these enabling technologies will provide versus what is possible with typical applications today—along with the challenges that these technologies address.

And finally, given that the IIoT is already ten years in the making, we asked for their assessment of the progress and overall impact of the IIoT on industrial automation and smart manufacturing to date, and what are the key next steps and/or technologies that will enable more rapid development of IIoT applications.

Cloud, edge and Industrial 5G

Key IIoT enabling developments are continuing refinements of cloud, edge and Industrial 5G technology solutions with a focus on the needs of IT/OT convergence. The reality is that the potential of the IIoT depends on tight integration between operating machines, on one hand, and business information systems, on the other.

Katrin Kunz, Head of Marketing for SIMATIC IPC/HMI/IoT Products at Siemens said she expects the convergence process to continue to develop, aided by new cloud and edge computing solutions along with the emergence of Industrial 5G.

“I expect the OT and IT worlds to grow even closer together,” Kunz said. “This will result in a greater degree of networking of IoT devices. At the same time, the data volumes to be handled will continue to increase. IoT systems in the cloud and edge computing environment will continue to develop,” Kunz stated. “The number of cloud and edge apps available on the market will explode. And I am sure we will see more and more virtual reality and artificial intelligence installations.”

She added that industrial security will certainly become increasingly important in connection with these developments. In addition, open IoT ecosystems will form, from which device manufacturers, app developers, and service providers will benefit massively in the coming years. In industrial communications, she also expects Industrial 5G to become increasingly established on the market over the next few years.

“This focus not only on the technology is needed but also on the business change required. I am sure many enterprises will realize that investing in an IoT solution is only one step to solving the business problem and integrating it into the business processes that it seeks to impact,” Kunz added. “Vendors and service providers need to find ways to adjust the messaging to talk about the business process change and how the technology will support it.”

Creating IIoT solutions that work from the sensor to the cloud is requiring new system architectures that enable higher levels of data accessibility.

IIoT: unprecedented flexibility

First of all, Kunz wanted to emphasize that traditional implementations and IIoT implementations with cloud and edge computing will coexist. Most applications can be implemented traditionally or with IoT technologies. From her point of view, IoT technologies result in unprecedented flexibility and agility. The price companies have to pay as a basis is standardization.

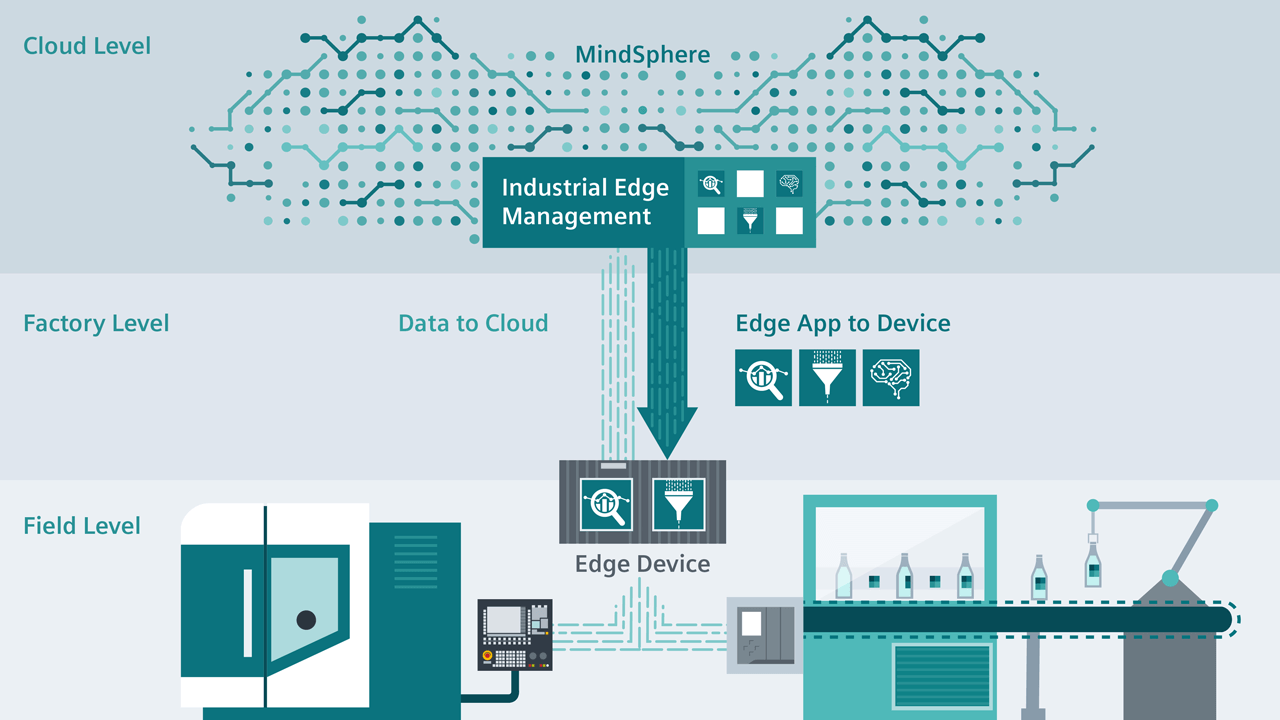

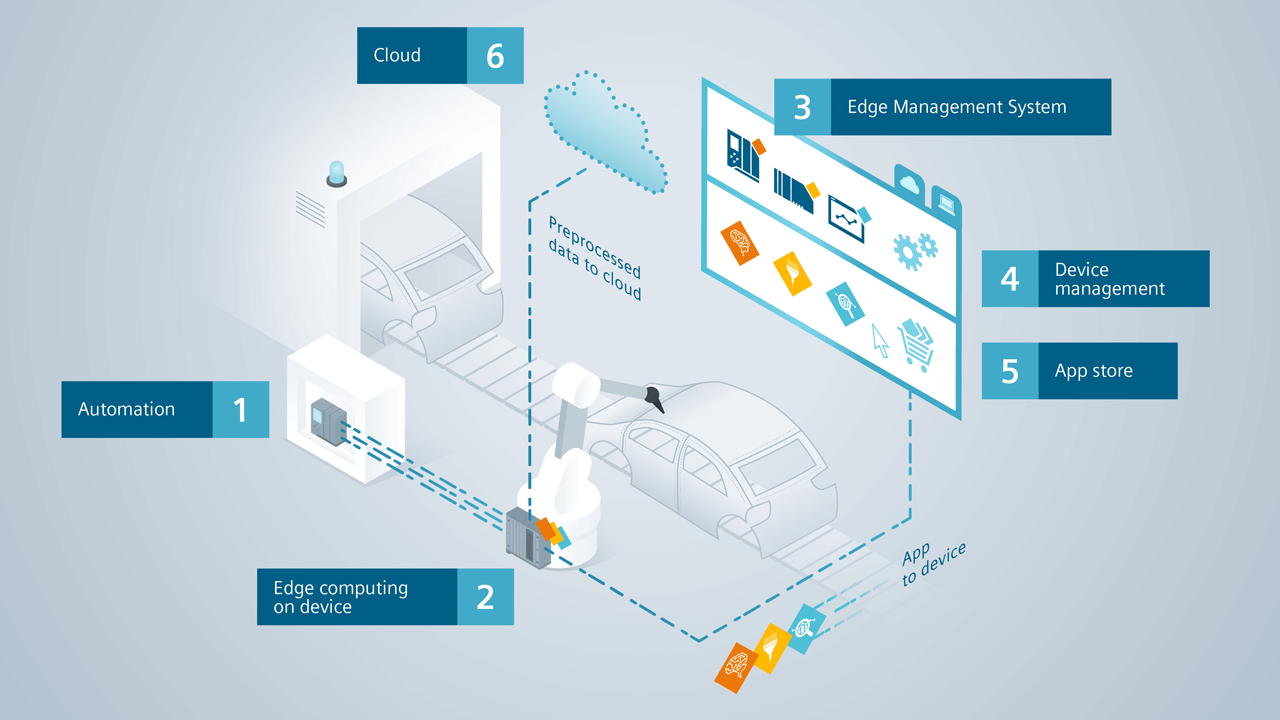

“With edge computing and in our case Industrial Edge evolving as open ecosystem of solutions, devices and apps, customers are able to flexibly realize IoT solutions close to machines – best integrated into industrial automation,” she said.

Companies can introduce applications like data analytics or AI to the shop-floor close to the machine in less time to increase the productivity of machines & plants even further. Furthermore, shop-floor users are empowered to manage machine parks and plants by choosing and centrally deploying best-in-class applications from an open app store.

“With cloud computing and, in our case MindSphere, IoT solutions are powered from the edge to the cloud with advanced analytics and AI. Customers can connect and analyze data from connected products, plants and systems to optimize operations, create better products, and enable new business models. Built on the Mendix application platform, MindSphere empowers customers, partners and the Siemens organization to quickly build and integrate personalized IoT applications.”

Industrial Edge allows user to analyze all data at the machine or preprocess it quickly and instantly. The optimized data points can then be transferred more quickly to the cloud where, for example, you have access to more computing power and larger storage capacities.

Challenges for automation & control

Kunz stated she thinks the biggest challenge for automation and control engineers is to embrace the new/unknown. Company leaders, automation and control engineers, but also employees need to be open, trained in IoT technologies and industrial security. Especially in IoT projects, it is important to understand that the technology is one thing, and the implementation of processes and change in the minds of the workforce is another. Everyone who ends up working with IoT technologies needs to be aware of what he/she is doing, and also what can be done in the process.

Standardization is the foundation for any digitization project. But what is also becoming increasingly important is to understand the company data and its semantics in detail because, without that, it will be difficult or impossible to implement artificial intelligence.

“We are all in a huge change process right now. I believe that the influence of the IIoT is already great today, for industrial and process automation as well as for smart manufacturing,” Kunz said. “Its importance will increase massively in the coming years and decades.”

She cites low code programming and Siemen’s low-code application platform (all-in-one-platform) that is making it possible for anyone to be empowered to build, integrate and extend applications 10x faster, with 70% fewer resources. Customers are enabled to increase operational efficiency, modernize core systems, launch new products and create digital experiences, backed by the Mendix developer community and industry-leading, low-code capabilities as well as cloud services, and industrial and business services.

IIoT: data in the forefront

One key trend with the emergence of the IIoT is the ability for companies to better use and leverage large amounts of data. This ranges from better remote access to equipment, use of data for more resilient operations, and simulation and emulation tools to reimage machine operation and workflow.

“Industrial companies have accelerated their adoption of remote access at blazing speeds during the pandemic. With onsite access for equipment experts, limited use cases for remote access have expanded, such as for equipment demonstrations, factory acceptance testing, and troubleshooting and maintenance,” Jessica Forguites, Product Manager at Rockwell Automation told IEB recently. “This is made possible with a foundation that includes a network architecture based on standard and unmodified Ethernet, and high-performance smart devices with gigabit speeds and security features.”

Another trend is the use of IIoT data to create more resilient operations. Supply chain issues that emerged during the pandemic and other challenges like the skills gap and limitations of people inside of facilities have created a need for companies to improve resiliency enterprise wide. They’re doing that by using newer innovations like closed-loop scheduling, self-aware systems and smart objects. They’re also making investment in MES and analytics solutions to drive labor efficiencies, tighten integration between production and material planning, and meet quality and regulatory requirements.

Tools like simulation and emulation software are also using digital twins to help reimagine work, from iterating designs before steel is cut, to testing the controls for a machine before it’s bolted to the floor, to creating experienced workers before they touch live controls.

Remote access technologies

Forguites said that secure remote access is helping keep workers safe by allowing them to do their jobs from home. But companies are also using it to transform and improve how those jobs are done. OEMs, for example, can combine remote access with other technologies like a digital twin and augmented reality (AR) to do remote virtual demos of new equipment. Production workers can also connect with remote experts to more quickly resolve problems, without waiting for the expert to fly in. Using AR technology, remote support can even be enhanced with drawings and overlays that are placed directly on the machines in front of the production workers.

“Meanwhile, IIoT applications that strengthen resiliency can simplify jobs and optimize operations. Closed-loop scheduling can automate and optimize daily schedules,” Forguites added. “Self-aware devices can automate device configuration and ease maintenance. And innovations in control system designs like smart objects can greatly simplify data science by allowing data to be automatically organized, modeled and consumed by IoT systems, with little to no effort from a programmer. In one case, a company estimated it would have taken a developer one month to do what smart objects enabled in only six hours.”

Working through the pandemic

The pandemic has changed work as we know it in the industrial world. For some companies, this has led to new and better ways of working. At one chemical company, secure remote access helped employees remotely deploy two new facilities during the pandemic. This helped keep employees safe, improved overall efficiency because of reduced travel needs and improved system support coverage. The company now plans to use this approach to start-up and commission all of its facilities.

Forguites said that the skills gap is another top challenge facing industry. Retirements of skilled employees are mounting, and technologies and processes in production facilities are becoming increasingly complex. Analytics software that turns raw production data into useful, real-time information can give less experienced workers helpful insights into production and answer their pressing questions. What’s more, companies can use analytics software for real-time workforce performance monitoring. This can help them understand how long a process is taking an operator and uncover ways to improve productivity.

Innovations like smart objects also reduce the demands put on engineers and data scientists by streamlining data preparation. And self-aware devices help simplify device integration and maintenance.

“Digital transformation has forever changed how people make things. And it’s clear that industry’s biggest needs today are best addressed with digital initiatives,” Forguites said.

Companies that are well underway on their digital journeys are already discovering what’s possible and demonstrating value of these investments back to their organizations. One company facing a skilled worker shortage established a new center to provide support and collaboration for its hundreds of global production facilities using remote monitoring and predictive analytics. In another case, AI-driven predictive maintenance and asset optimization helped global mining operations save hundreds of thousands of dollars in unnecessary spend.”

As companies undergo digital transformation, they should remember that it’s an ongoing journey. They should try to learn from early successes and failures, not only in their digital initiatives but also those of organizations. Make sure initiatives incorporate what have proven to be the best practices of digital transformation, executive sponsorship, a roadmap, a change-management plan, comprehensive cybersecurity and a partner that can bridge internal gaps.

Importance of cybersecurity

Cybersecurity is a non-negotiable component of any digital transformation. But companies must make sure they tailor cybersecurity to the unique risks, network activity and requirements of operations environments. Visibility and threat detection software should be able to explore the deepest level of industrial network protocols to identify even the smallest of anomalies. The software should also use a passive monitoring approach to inspect traffic without the risk of disruption.

Using control products with CIP Security is a way to tailor cybersecurity to the operations environment. CIP Security is the only standard designed to secure communications between industrial control systems and other devices on an EtherNet/IP network. Companies should also make sure that they and their suppliers comply with global security standards, such as ISA/IEC 62443 and ISO 27001.

“Companies should map out their process workflows. That’s important from a security standpoint, Forguites said. “But it can also help keep track of the many system and data point connections, especially as those connections grow over time. Software tools and services are available to give companies visibility into their network connections.”

Emergence of edge computing

Traditional industrial communication systems address data processing from a hierarchical perspective, as with the classic Purdue model. One good feature of this hierarchy is the clarity it provides with regard to where data can originate, be stored, undergo processing, and be delivered.

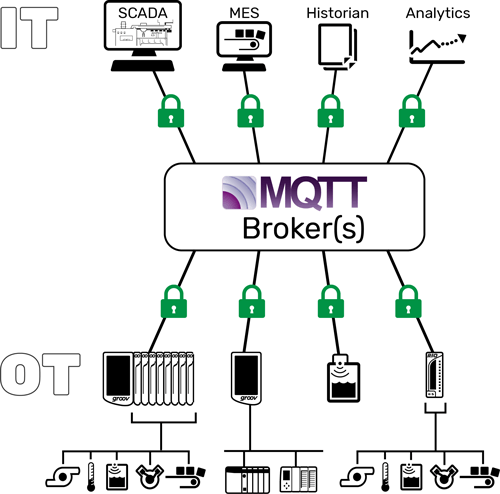

The basic structure of an MQTT network, clients from OT and IT communicating through an MQTT broker.

However, the task of transporting data and processing it in context is often quite difficult, because so many layers of equipment and software are required to connect devices and applications.

“The hierarchical approach was necessary when computing capability, network bandwidth, and security features were much less available,” Josh Eastburn, Director of Technical Marketing for Opto 22 told IEB. “Each step up the hierarchy from a basic hardwired sensor to cloud computing systems was required to access greater computing and networking resources. It also clearly delineated the security measures networks required around unsecured field equipment.”

“Now, industrial edge computing is changing the relationship between field assets and the systems that collect and use their data. Complementary to this, MQTT/Sparkplug B is gaining traction as a potential industrial standard, enabling large-scale interoperable IIoT communications. Together the two technologies are laying a foundation for widespread IIoT.”

Benefits of edge technology

Traditional industrial devices are designed for a narrow scope of operation with limited software/firmware tools and protocols outside of I/O and control networks. Specifically, they lack functions that would make them compatible with other parts of the enterprise, most notably standard IT security and communication formats. They also lack the computing capability to deal with large and complex data volumes.

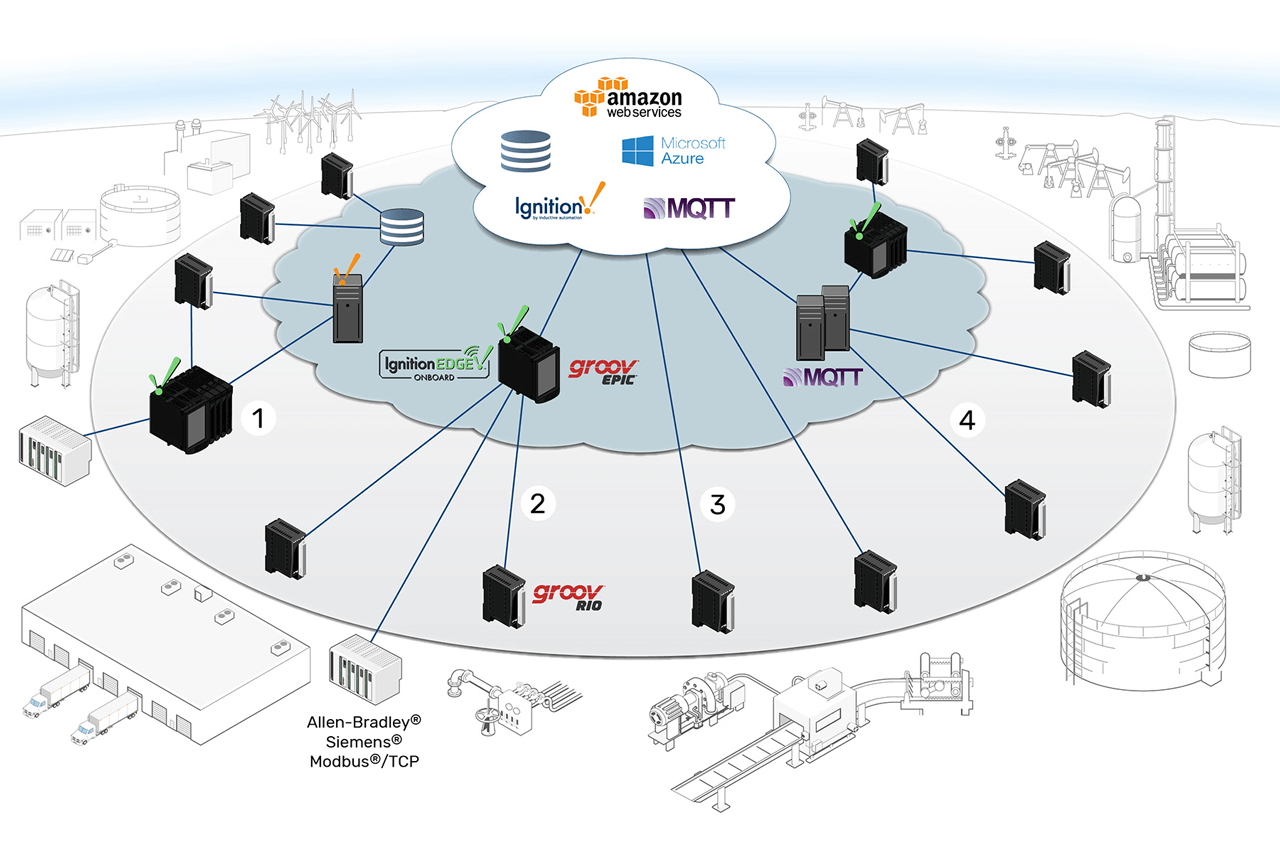

According to Eastburn, industrial edge devices provide general-purpose computing, networking, and storage directly to the process, sensor network, or field of operation, enabling them to overcome these traditional limitations. Opto 22’s groov family of edge devices, for instance, implements centralized user authentication, device firewalling, TLS data encryption, certificate management, VPN, and so on. They also support data processing and communication directly to databases, cloud services, and other applications using tools like Node-RED.

“Within that infrastructure, MQTT can provide communication that is 80-90% more efficient than traditional poll-response protocols because of its lightweight format and brokered report-by-exception communication pattern,” Eastburn added.

“And because client connections are outgoing (device-originating), edge device firewalls can completely block outside connection requests while still providing bi-directional communication. Building on top of this, Sparkplug B defines an interoperable data exchange format for MQTT communications with a data-rich payload structure that supports a unified namespace where IIoT communication can happen across the organization.”

Flexible, scalable architectures

IIoT growth requires, first and foremost, scalable architectures. Scalability is a combination of cost-efficiency, driven by the efficiency of the underlying communication mechanisms, and the quality of cybersecurity and other factors affecting data integrity (You can’t scale if it costs too much or isn’t safe).

Unfortunately, the traditional, multi-layered Industry 3.0 technology stack inflates integration costs and reduces efficiency because of the complexity required to introduce new connections between applications and devices.

The connectivity and data processing embedded in industrial edge devices provide simple, comprehensive integration options that reduce the cost of expanding the network. Rather than navigating layers of infrastructure, they can send process data directly to business applications, cloud services, and so on.

They can further flatten the architecture by assimilating automation functions typically given to PCs, like hosting database, communications, and HMI servers; running custom applications; or bridging disparate automation networks. They can also provide secure gateway functions to integrate legacy control systems and equipment.

MQTT overcomes similar challenges, improving data security and reducing bandwidth consumption without requiring investment in new infrastructure, because it is built around scalable architectural concepts. Rather than focusing on point-to-point connections, MQTT traffic is routed through an MQTT broker, which handles distribution to all clients. It creates a one-to-many relationship between clients that is much easier to scale up than many direct connections.

Four examples of new architectures that are possible with industrial edge devices: 1) Shared infrastructure with edge data processing; 2) Legacy device integration with edge controller as IoT gateway; 3) Direct-to-cloud I/O network; and 4) Many-to-many MQTT infrastructure.

Early days for IIoT

“These are still early days for the IIoT. These projects have largely been taken on by well-funded industry players and are only recently becoming a possibility for the typical system integrator, manufacturer, etc. as we put forward technologies that are efficient and effective,” Eastburn said.

Key next steps and/or technologies that will enable more rapid development of Industrial Internet of Things applications in the future include:

- Considering alternative architectures: IIoT is prompting an evolution in technology, but if you don’t grasp the concepts behind that evolution, you can misapply the technology and fail in your IIoT goals. Trying to do the same thing bigger or faster is not what IIoT is about. Understand what it could mean to reorient your infrastructure for scalable communication across the entire organization.

- Having a conversation with your IT group about security: Security is a traditional sticking point between IT and OT personnel. Edge computing with MQTT makes it possible to resolve this disconnect but you may still encounter a lot of skepticism. Make the effort to understand best practices and demonstrate to your IT counterparts that you can meet those requirements. Then you can proceed with a conversation about what is possible when your networks are safely connected.

IT/OT Convergence

One trend that is driving the IIoT forward is the primary need for convergence between Information Technology (IT) and Operations Technology (OT) within the smart factory.

Digitalization of products and systems opens the opportunity to deliver new and enhanced software solutions and enables new digital services and business models. But the implementation of these concepts is made more difficult because of the heterogeneity of communication protocols at the field level.

According to a technical paper from the OPC Foundation, although most of today’s fieldbus systems and real-time Ethernet protocols are standardized by IEC in the 61784/61158 series, automation devices supporting different protocols are not interoperable with each other and often cannot coexist in a common network infrastructure. In addition, device information is structured using different information models, which makes data analysis a labor-intensive and time-consuming task that is also vulnerable to errors, especially in multi-vendor and multi-protocol environments.

However, the trend of moving to seamless interoperability accelerated by the dawn of the Industry 4.0 and Industrial Internet of Things (IIoT) era requires industrial system integration to become vendor-independent and to support end-to-end interoperability from sensor to cloud, including field level devices for all relevant industrial automation use-cases, including real-time, motion, and functional safety.

“Standardized communication from sensor to cloud will support the digital transformation across all industries, including factory automation and process automation,” the report states. “End users, machine/skid builders and system integrators will benefit from easier system integration and cross-vendor interoperability. Seamless access to production data and process conditions will facilitate availability and optimization of production processes.”

This approach requires standardization to take place on multiple levels: semantics, information modeling, communication protocols, data link layer and physical layer – all embraced by a common cyber-security framework.

An important aspect is the convergence of information technology (IT) and operational technology (OT) allowing a common network infrastructure to be shared by IT and OT traffic while guaranteeing different levels of quality of service (QoS) demanded by diverse IT and OT applications.

APL and TSN technologies

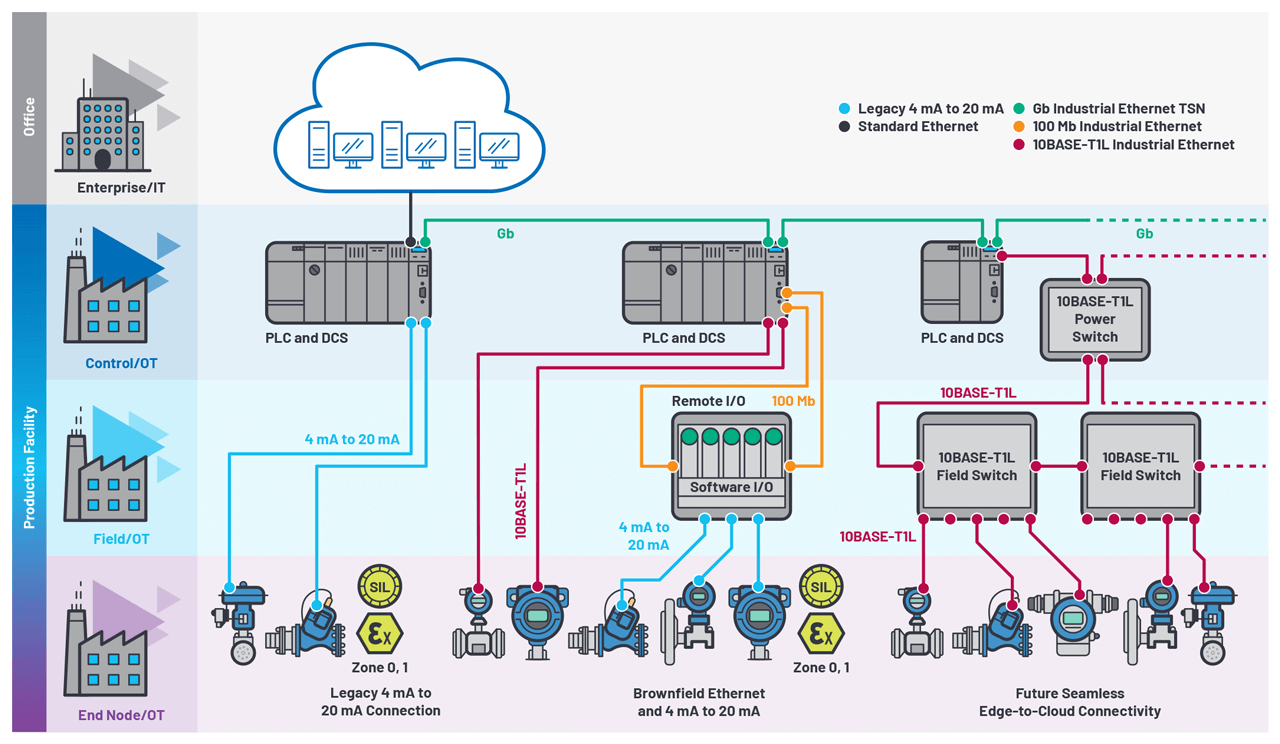

Technologies that the OPC Foundation report singles out as having particular importance are the Ethernet Advanced Physical Layer (APL) and Ethernet Time-Sensitive Networking (TSN). APL facilitates seamless Ethernet connectivity down to the field level, including long cable lengths and explosion protection via intrinsic safety with power and communication over two wires.

TSN enables deterministic communication on standard Ethernet, allowing IT and OT protocols to coexist in a common network infrastructure.

The OPC Foundation’s Field Level Communications initiative was established in November 2018 to specify extensions to the OPC UA framework in order to standardize the semantics and behaviors of controllers and field devices from different manufacturers. The main use cases covered by the initiative are controller-to-controller, controller-to-device, and device-to-device including support for IIoT connectivity for both controllers and devices (controller-to-compute and device-to-compute).

The technical work is being performed in OPC Foundation multi-vendor working groups that define the technical concepts and specify the different mechanisms to achieve these goals.

Horizontal/vertical connectivity

“The goal of digitalization is to foster the integration of IT technologies with OT products, systems, solutions and services across their complete value chains, which stretches from design and production to maintenance. Once implemented, digitalization of products and systems opens the opportunity to deliver new and enhanced software solutions and enables new digital services and business models.”

The Internet of Things (IoT) brings together a broad range of technologies to those OT products, systems and solutions that have traditionally not been connected via today’s near ubiquitous IP-based networks. While Ethernet provides the ability for things to ‘reach’ each other, they still need a common way to communicate. Standardized data connectivity and interoperability addresses this need.

The report says that, in simple terms with standardized data connectivity at its core, the Industrial IoT (IIoT) can be looked at from two perspectives: horizontal and vertical data connectivity. An example of horizontal communications is to be clarified: controller-to-controller (C2C) data connectivity between shop floor systems.

An example of vertical communications is device-to-cloud data transfer. In both cases, the OPC Unified Architecture (OPC UA) standard from the OPC Foundation provides a secure, reliable, and robust foundation to facilitate standards-based data connectivity and interoperability.

For years, many companies and partner organizations have openly worked together under the umbrella of the OPC Foundation to make this a reality and will keep doing so as it continues to expand its collaboration activities.

“A key aspect of improving horizontal and vertical data connectivity is network convergence supporting a common network for IT and OT-related communication. Ethernet Time-Sensitive Networking (TSN) according to IEEE 802.1 supports communication with bounded latency and jitter,” the report added.

“In addition, various data streams, and traffic types can be transmitted over a common network infrastructure, while at the same time guaranteeing the various bandwidth, latency, jitter and reliability requirements of the different applications. Therefore, TSN plays a key role in supporting the convergence of IT and OT. The Ethernet Advanced Physical Layer (APL) is another key technology to drive network convergence as APL delivers seamless Ethernet connectivity to sensors and actuators in process automation – including hazardous areas.”

Field Level Communications

The OPC Foundation announced recently that its Field Level Communications Initiative has accomplished a significant milestone in the ongoing project by completing their initial release candidate with the focus on the Controller-to-Controller (C2C) use case. In addition, a technical paper has been published that explains the technical approach and the basic concepts to extend OPC UA to the field level for all use cases and requirements in Factory and Process Automation.

For more information, download the “OPC Foundation FLC Initiative Technical paper”.

Connectivity megatrends

The deployment of increased numbers of Industrial Ethernet connected edge nodes across both factory and process facilities will result in operations managers having data at their fingertips to optimize operations and inform decision making.

According to Fiona Treacy, Strategic Marketing Manager–Industrial Communication for Analog Devices, the digital or smart factory and the evolution of connectivity networks is one of the megatrends driving IIoT markets in 2021.

In combination with the increased deployment of condition-based monitoring technologies across the factory floor, this will enable new data streams to be activated and utilized to increase productivity. The deployment of increased numbers of Industrial Ethernet connected edge nodes across both factory and process facilities will result in operations managers having data at their fingertips to optimize operations and inform decision making.

Also coming on stream is the advent of 5G technology, bringing with it the wireless connectivity needed for AMR’s (Autonomous Mobile Robots) which will see them make more strides toward the realization of their full potential. Finally, as more and more devices become connected and interconnected, the security burden is increasing for all, with 2021 likely to bring new solutions and technology’s with partners working together to scale solutions.

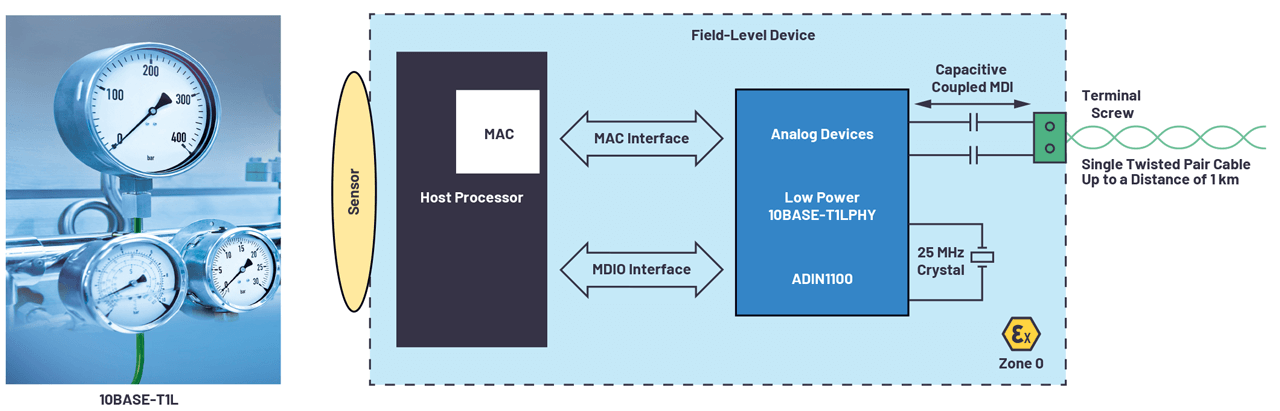

“The launch of Single Pair Ethernet, 10BASE-T1L physical layer devices will prove a game changer on the road to realizing edge node connectivity. Enabling both power and data to be transmitted over a single twisted pair cable up to 1km in length,” Treacy stated. “For the first time we will see devices across process facilities directly become IP addressable. This will change both the control network topology but also the maintenance and deployment burden. It will now be possible for Field devices to be programed or reconfigured from any connected devices without the need to deploy service personnel.”

The increase bandwidth of 10Mbps will enable new data streams to be transmitted beyond control data, like auxiliary device variable or other health parameters. This new information will enable the optimization of processes and the increase in asset utilization. 10BASE-T1L connectivity promises to extend the benefits of IIoT to the remote corners of factories and process plants, where sensors and other endpoints were until now out of reach of the enterprise network.

Emergence of TSN

Treacy said that the second key technology coming closer to fruition in 2021 is Time Sensitive Networking. With the hardware portions of the standard mostly completed, we expect to see the first TSN compliant layer 2 switching technologies sampling into automation equipment vendors. Time sensitive networking (TSN), is foundational for meeting the many powerful outcomes of IIoT. With TSN, all data across the factory—from the floor to servers, front office, and everywhere in between—can coexist and communicate.

A third trend that Analog Devices sees is Gbit technology starting to dominate in new designs with vendors seeking to future proof beyond 10/100Mbit speeds.

Challenges for users

Both new technologies will provide control and automation engineers more visibility into their production environment by providing access to enhanced data streams. With TSN being the first step to breaking down existing data silos that hinder seamless connectivity, it can enable ubiquitous access to precious, decision-making data.

TSN will create a common language that will enable equipment from different manufactures coexist on the same Ethernet network. It enables real-time, deterministic data crucial for accuracy and precision in control environments. Finally, it will help to close the divide between Information Technology (IT) and Operating Technology (OT) specialists, by providing a common set of tools, in support of a converged network.

“10BASE-T1L will provide new insights from previously unconnected devices in remote locations and enable automation engineers to transform their commissioning and upgrade work practices,” Treacy stated. “In conjunction with new analytics software these new data streams will enable the extraction of actionable information and inform control engineers decision making. It will help drive changes in maintenance routines, scheduled downtime planning and moving toward more active predictive maintenance approaches.”

10BASE-T1L enables both power and data to be transmitted over a single twisted pair cable up to 1km in length.

Impact of the IIoT

The benefit of IIoT and the Smart factory are clear for all to see, however the reality of retrofitting existing facilities to avail of the benefits and upgrading connectivity networks takes time and requires an outlay of capital. Undoubtable there are pocket of industries and segments of factories that are making great strides toward the realization of the vision.

Treacy said that having a clear goal around the data and information required and how it will be leveraged to drive output will help business owners grapple with the cost benefit analysis and enable clear ROIs to be realized in the long run. As 2021 unfolds we are likely to see more proven use cases come to attention which will help crystalize the benefits and opportunities gained from those who invested early in lifecycle.

“In 2021, I am excited to see the launch of the first 10BASE-T1L enabled field instruments and field switch devices. These foundational products will be the first step toward a network of 10BASE-T1L connected instruments across process facilities worldwide and will bring the benefits of increase data, power, and IP addressability to life,” Treacy said.

She added that the roll out of some TSN enabled automation equipment prototypes at the controller level will enable the use cases with existing Industrial Ethernet Protocols to be firmly tested.

“Finally, we need to enable the transition from existing legacy analog communications to Ethernet technology. For this reason, we expect to see the roll out of software configurable I/O devices which can be configured as needed to meet the deployment use case in retrofitting projects. This will support a hybrid deployment of both Ethernet and legacy analog and provide flexibility to enterprise to leverage existing investments while upgrade segments of facilities in a phased approach,” she added.