TechnologySeptember 10, 2018

Optimising automation with IIoT information

As manufacturing companies strive for higher Overall Equipment Effectiveness (OEE), the emerging trend driven by the IIoT technologies to collect and utilize useful feedback from a machine, or from an entire manufacturing line, can be critical to unlocking the potential of the equipment.

Feedback and how a system reacts to that feedback, is the key to any good motion control system. The same can be said for almost any type of industrial machinery. When a machine user is armed with feedback from the machine, this information can be used to optimize operation performance, efficiency, and consistency.

This trend in manufacturing to collect and utilize useful feedback from a machine or from an entire manufacturing line is sometimes referred to IoT (Internet of Things), Industry 4.0, or Cloud Computing. As manufacturing companies strive for higher OEE, this information can be critical to unlocking the potential of the equipment.

Automation companies have built functionality into their products to allow the user to access all sorts of information from the automation products themselves and from the equipment they are automating. This information can be crucial in diagnosing issues that result in downtime while at the same time unlocking untapped machine output potential.

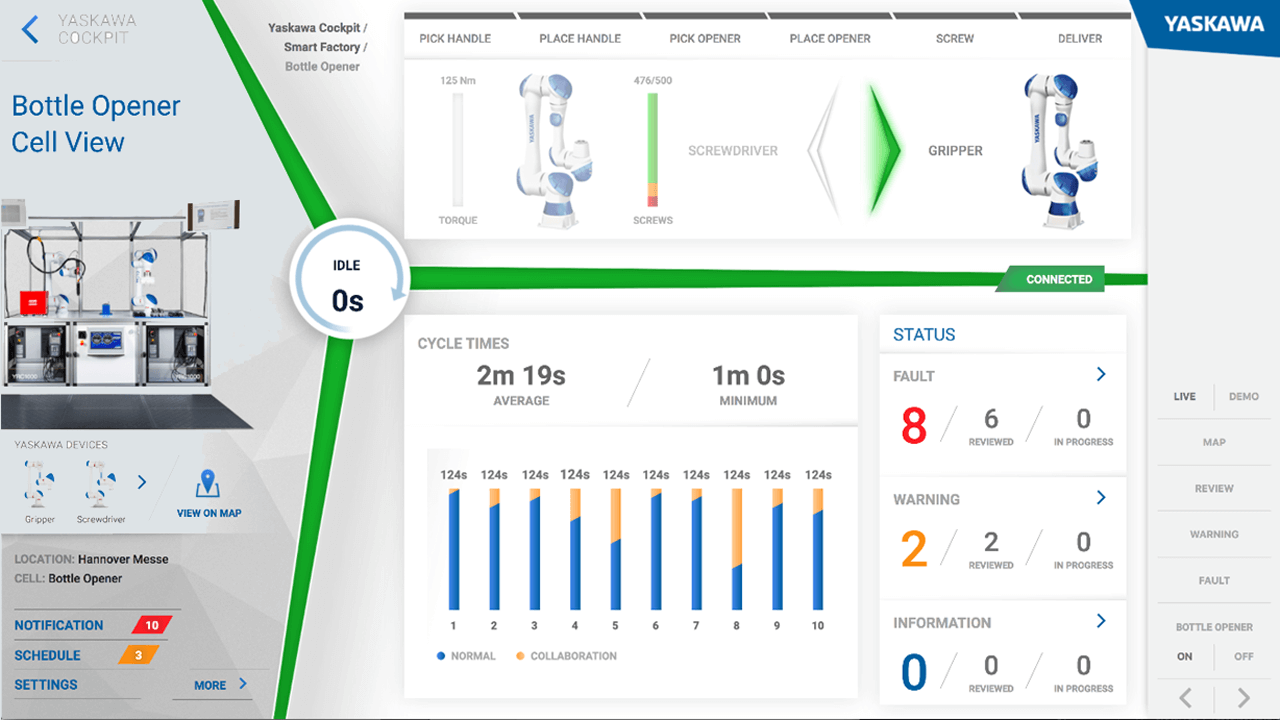

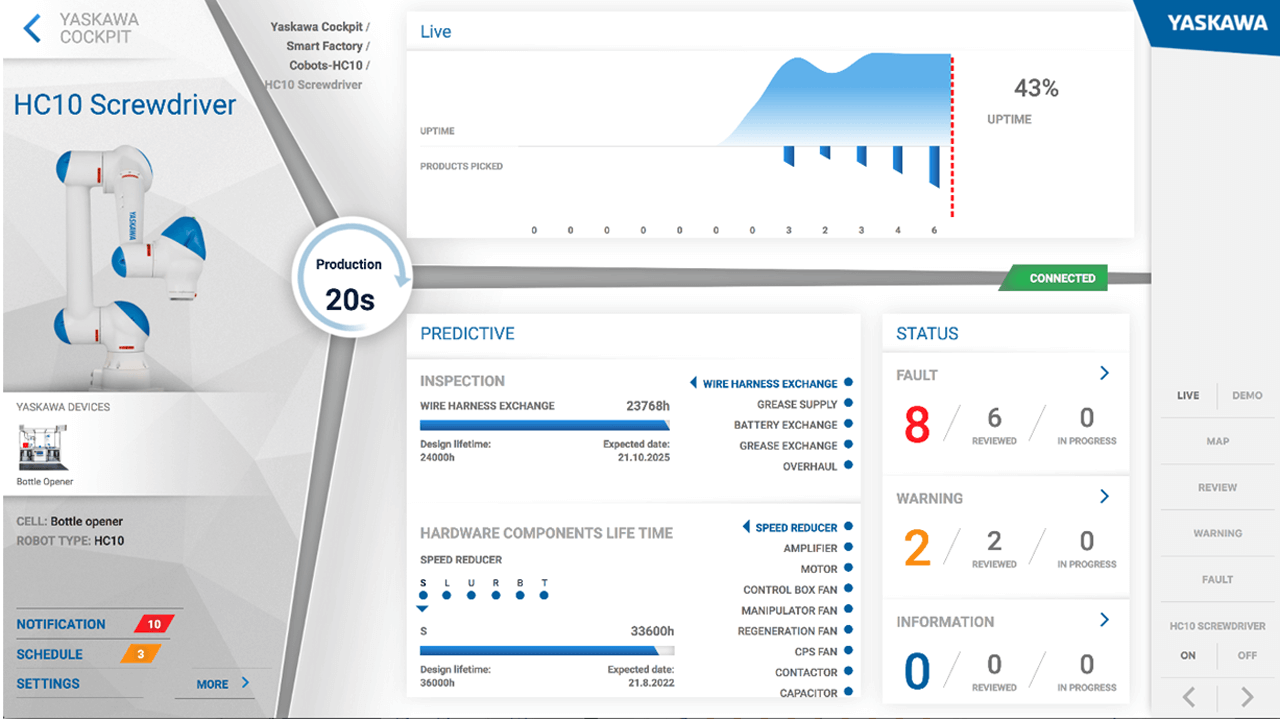

Examples screens from visualization tool.

Examples of useful information

Variances in operating temperature of a servo motor can indicate changes in machine mechanics. Servo motors only draw as much current as is required to meet the application needs.

Increases in servo motor temperature (which directly relates to the current draw) can most often be attributed to worn mechanical transmission components. This information could be used to in a preventative maintenance program where mechanical components get lubricated or replaced when their efficiency starts to drop.

Life monitors on critical wear components of automation equipment can be used to predict failures before they happen. Machine operation can be optimized by scheduling component replacement prior to a catastrophic failure that could shut down the manufacturing line.

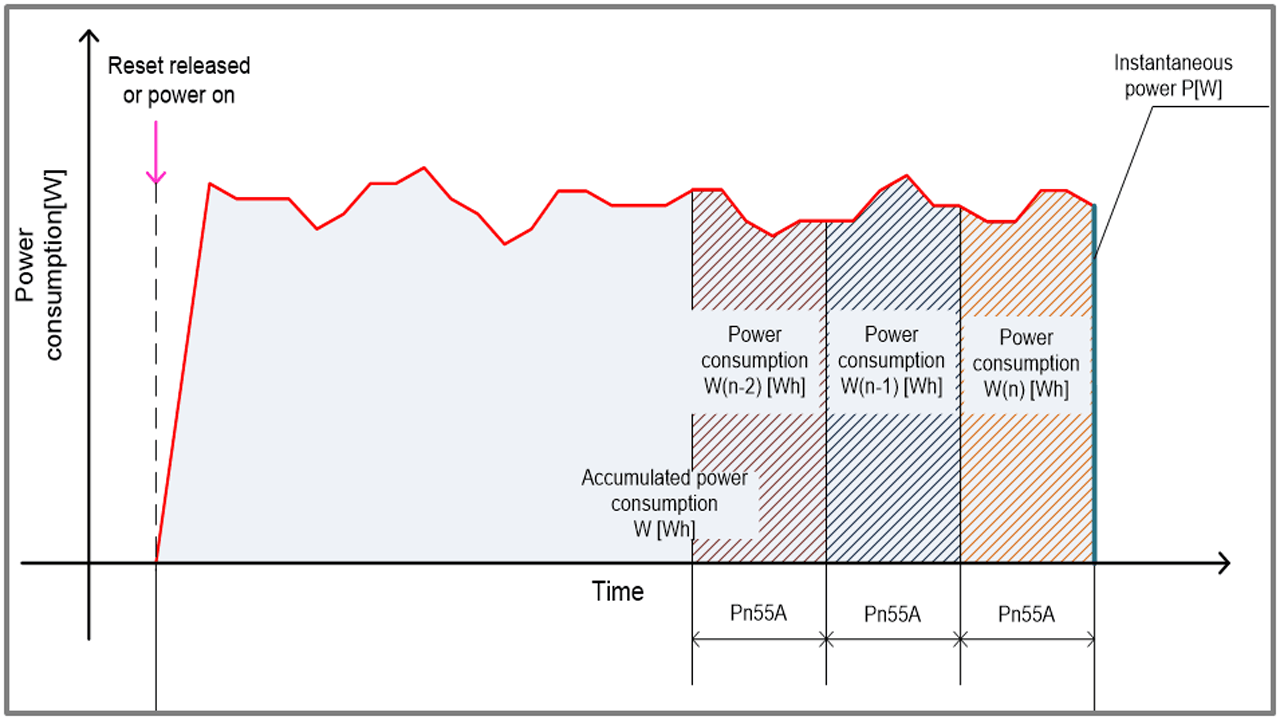

Electricity consumption monitors can highlight inefficiencies in individual machines or entire manufacturing lines. This information could be used to adjust machine cycles to minimize overall electricity consumption or to maximize energy consumption during certain times in the day when energy is less expensive.

FFT (Fast Fourier Transform) analyzers can provide a visual representation of what frequencies are present in a given set of machine data. These FFT “fingerprints” for each machine axis can be used to identify specific changes in machine mechanics over time and the life of the machine.

Communicating information

The availability of information is important, but having a tool that organizes the information and suggest actions for improvement can be just as important. Some automation vendors have created customizable toolboxes that display the types of information described above as well as statistics related to the efficiency and performance of the machine or manufacturing line as a whole. These toolboxes can typically be viewed on the machine HMI or from anywhere in the world via a secure internet connection.

Electricity consumption monitors display from Yaskawa SigmaWin+ software.

Tools such as this can be used for visualizing the operations of a single machine, a manufacturing line, or an entire factory. They can provide asset management information, predictive maintenance schedules, alarm forwarding, and data management. They can also exchange communications with external systems through OPC-UA. These tools have this base functionality but are also highly customizable.

The wealth of information available with today’s automation systems coupled with the highly engineered tools for organizing and distributing the information can be of enormous benefit to machine builders and machine users. Increases in machine throughput, higher part quality, reduction in machine downtime, and increases in machine life are all achievable outcomes when machine and manufacturing line feedback is utilized effectively.