TechnologyMay 30, 2021

Real world advancement and advantages of IT/OT convergence

Going beyond the buzzword, a truly converged business means that decision makers can see and control all aspects of their operation through a single pane of glass. As use cases and adoption of SPE continue to grow, so do our capabilities of actually making effective use of convergence.

Looking at the developments shaping IT/OT convergence, a retrospective emerges on the evolution of industry and the technology that enables it. Over the past five years or so, “convergence” has become one of our industry’s most bastardized buzzwords. This once-novel concept has been relegated to an eye-roll inducing marketing fodder that has all but lost any real world meaning. Or has it?

As we crossed the one year mark of living and working in the COVID era, I couldn’t help but reflect on the changes that our industry has been through over the past few years. Changes that helped industrial manufacturing adapt during a year of unexpected and unprecedented operational and economic challenges.

Some changes better than others

Like most organizational bodies, the standards community moved to 100 percent virtual settings to conduct business. We were able to maintain effectiveness and accomplish goals, but it became abundantly clear that when it comes to clear communication there’s no substitute being in a room with somebody.

Exchanging the option of asking a colleague to discuss the information they presented at a conference over a beer or coffee for the option of learning more by extending a three hour Zoom call isn’t something any rational person would prefer.

Reflecting on this one change affirmed something that previously felt equal parts obvious and radical: That clear and direct communication is the key to developing and deploying the innovations that will define the future of manufacturing.

This principle applies to both communication between people and the machines we rely on to build what we sell. For people, improved communication enabled convergence.

Walking down memory lane

Speaking as a representative of the OT community, I can say that we’ve benefited greatly from our IT brethren. The first spark of effective convergence that I recall goes back about 8 or 10 years when virtualization was new to OT and we were researching use cases and determining how to best productize the practice.

We would have been working from square one if not for an IT colleague who decided to cross the IT/OT barrier by offering to share what he knew about virtualization — something that had been used in building automation for while at that point — over a cup of coffee.

Back then an invitation for IT/OT collaboration was rare because ambiguity surrounding which team was responsible for different data moving through our facility created an environment of perpetual territorial tension. We don’t do that anymore.

We’ve evolved as people, professionals, and technologists and through years of improved communication we’ve learned to speak a lot of the same language.

The Manufacturing IT discipline is an example of our evolution. Effective convergence is easier to realize with people who are capable of understanding control and process needs but can also bring the rigor to communicate clearly with the corporate IT folks.

But the human element is only one side of the convergence coin. Unlocking the full potential of convergence requires that our machines also speak the same language and communicate clearly; with us and each other.

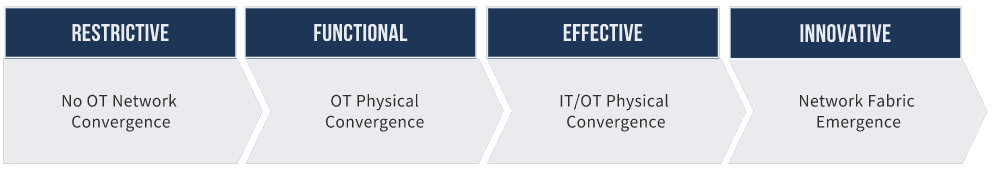

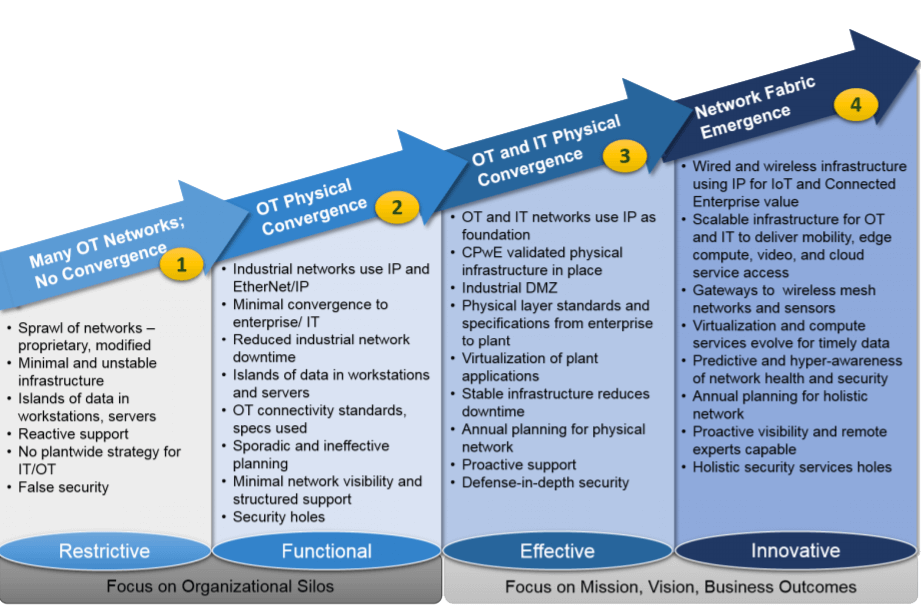

Current state of convergence

Convergence is already occurring in the modern industrial space and although each company may apply the practice a bit differently than the next, they all have the same question: What’s the next step to take full advantage of it?”

Technology moves quickly and increased adoption of more sophisticated tech like IIoT devices means more bandwidth, more information, and more data…but the same challenges with gateways. This is why companies that embrace the latest network solutions have the best foundations from a convergence standpoint and the best opportunity to take advantage of new data streams.

Utilizing advanced elements of virtualization and automation, like digital twin, enables machine learning algorithms that find opportunities to optimize plant efficiency.

Automating the data analysis gives plant operators a profound advantage. Since they’re spending less time manipulating data sets, they can focus on assessing the problem and deploying intelligent solutions. So what’s the catch?

What’s the most promising network upgrade companies can deploy to realize all of the hypothetical benefits that propelled convergence to buzzword status?

Single Pair Ethernet: The Universal Communicator

Convergence can deliver the information needed to optimize efficiency in any scenario. Game changing agility is possible, but not as accessible when the critical information at the edge of the OT network is running on various protocols and needs to be translated.

Convergence can deliver the information needed to optimize efficiency in any scenario. Game changing agility is possible, but not as accessible when the critical information at the edge of the OT network is running on various protocols and needs to be translated.

The sources of the mission critical information that’s absolutely needed to transact the manufacturing process, the components that are typically acquired from your favorite automation providers, are engineered to deliver specific data but not to connect any dots that will help increase operational efficiencies.

Operating at peak performance requires more than networking analog and legacy machines by installing sensors throughout the plant floor, uploading data sets to the cloud and looking for trends.

It’s possible that valuable insights can be discovered this way but they won’t give you access to the most critical element of streamlining operations: the context that demonstrates why things are happening.

SPE lays the foundation for a higher functioning, more secure network, instantly adding value to the enterprise by allowing OT to become an integral part of a single-protocol, seamless network, delivering on-demand access to federated data across the entire facility.

Now employees have the context and clarity required to make critical decisions, faster.

Let’s say a plant manager needs to increase manufacturing output to meet a spike in customer demand over the holidays. Since both IT/OT networks are Ethernet, the manager converges the data from the all facets of the business to find the right solution:

- Compute: Data center resources and network

- Enable: Spaces where the people sit

- Produce: The network that makes things

SPE enables the manager to take a holistic view of the facility’s status. The converged data shows reduced building occupancy because most of the staff are on vacation.

So now instead of just increasing yield, the manager dials down energy consumption across the entire building, except for in the data center which is undergoing server maintenance and needs to remain on the lower end of the temperature threshold.

This company just succeeded in meeting the manufacturing challenge at a better cost because of the visibility and access to controls across the facility – not just production.

Real world example

Three years ago my team and I at Panduit worked with a partner company that was developing a network infrastructure solution that aimed to change the way companies would think about eSCADA and process control systems. It was a digitally-enabled, unified system that provides integrated substation visibility through the same system that runs the rest of the plant.

Three years ago my team and I at Panduit worked with a partner company that was developing a network infrastructure solution that aimed to change the way companies would think about eSCADA and process control systems. It was a digitally-enabled, unified system that provides integrated substation visibility through the same system that runs the rest of the plant.

Installing the solution on top of the motor controls center responsible for all the reactive power loads in a business — motors, transformers, compressors, etc. meant the MCC is aware of and communicating with the utilities using IEC 61850 commands and enabling optimal demand response.

Where to start

People and companies who are hoping to better position themselves to take advantage of convergence and guide them to specific areas of the practice can start through education and certifications.

Cisco CCNA

Foundational certification to demonstrate that you know the basics of how to run a network.

Cisco CCENT

Validates the ability to install, operate and troubleshoot a small enterprise branch network, including basic security, WAN technologies, wireless concepts, routing and switching fundamentals, and configuring simple networks.

Experts: Cisco CCIE

ivalidate your end-to-end IT lifecycle skills from planning and design to operating and optimizing. This is Cisco’s top certification. Considering that less than one percent of people in the world and only 10,000 in the US have earned a CCIE, it’s incredibly valuable but isn’t necessary in many cases.

Industrial Control Systems Cyber Emergency Response Team (ICS-CERT) Trainings

ICS-CERT is part of the U.S. Cybersecurity and Infrastructure Security Agency and educates on how to prevent, track, prevent and resolve network threats.

Conclusion

Going beyond the buzzwords, a truly converged business means that decision makers can see and control all aspects of their operation through a single pane of glass. As use cases and adoption of SPE continue to grow, so do our capabilities of actually making effective use of convergence and not just talk about it like it’s marketing 101.