TechnologyMay 19, 2025

SPE/Ethernet APL: network infrastructure for the Industrial IoT

The potential is for Single Pair Ethernet and Ethernet APL to serve as the network infrastructure for the Industrial IoT, and the next generation communication architecture for automation. Originally developed for the automotive industry, now the promise is nothing less than a continuous connection from sensors to the cloud.

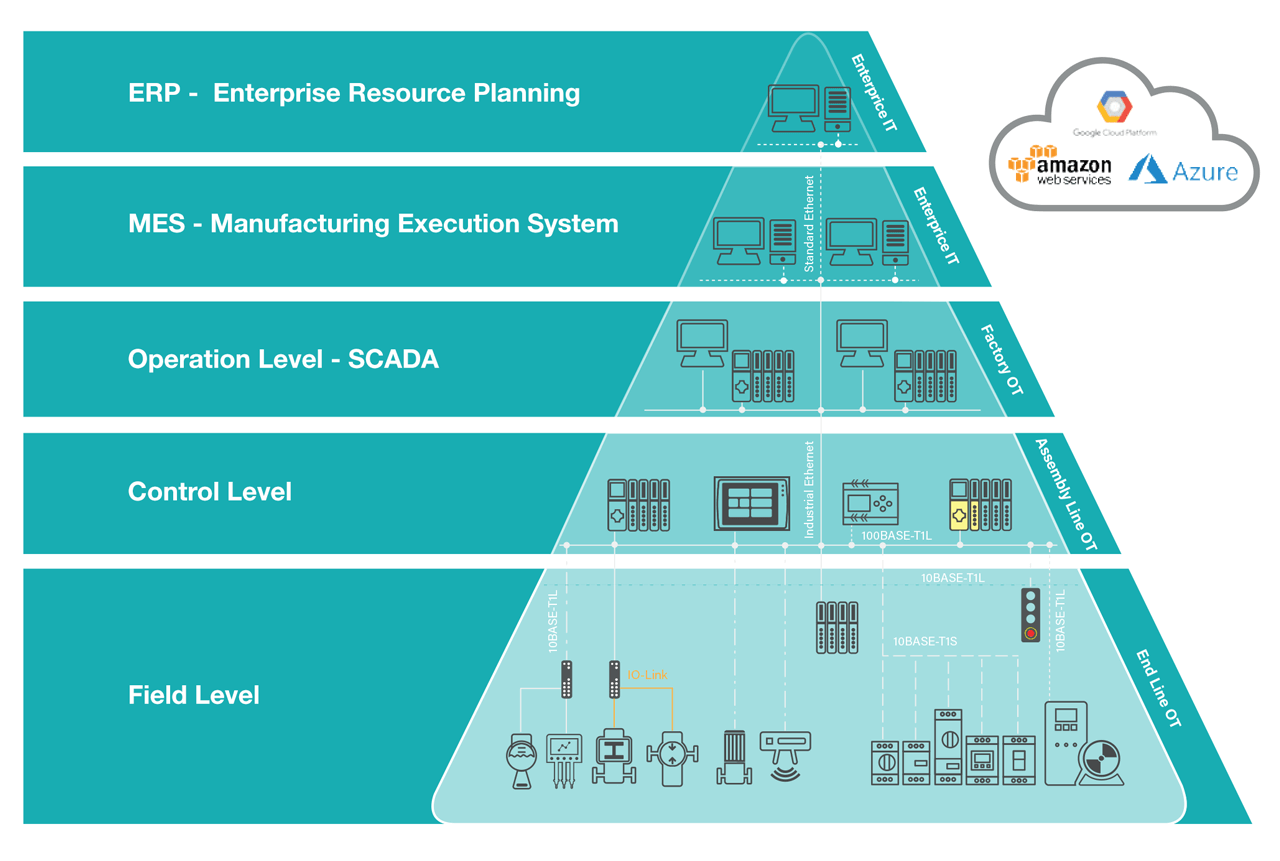

Single Pair Ethernet and Ethernet APL are being touted as providing the necessary infrastructure for the Industrial Internet of Things (IIoT). With SPE, Ethernet can communicate from the cloud to the field level in a space- and cost-efficient way for the first time. Ethernet-APL offers a ruggedized, two-wire, loop-powered Ethernet physical layer that uses 10BASE-T1L plus extensions for installation within the demanding operating conditions and hazardous areas of process plants.

The industry drive behind both of these technologies is progressing from idea to action, and several industry groups are working together to advance both technologies. This special report provides an update on progress and highlights the potential impact on smart manufacturing.

Single Pair Ethernet rollout

Expanding focus on device interoperability, standardization, and infrastructure development

The development and introduction of Single Pair Ethernet (SPE) is moving into a phase with a focus on testing, training and interoperability.

“The next steps in the development and rollout of SPE involve expanding device interoperability, standardization, and infrastructure development,” Kelly Passineau, product manager at Rockwell Automation told IEB. “For SPE, organizations such as ODVA, and industry alliances are working to refine standards like 10BASE-T1L and 10BASE-T1S for broader compatibility.”

“One major impact is the simplification of network architecture—offering a unified Ethernet-based framework from the enterprise level down to in-cabinet devices. This reduces wiring complexity, enables faster commissioning, and minimizes system integration challenges,” Kelly Passineau, product manager, Rockwell Automation.

Passineau said that another key step is developing robust testing procedures and conformance standards to achieve cross-vendor operability and plug and play functionality. Broader ecosystem adoption will be driven by increased availability of compatible sensors, actuators, switches, motor controllers, contactors, and diagnostic tools.

Lastly, training and education initiatives for engineers and integrators are also crucial to accelerating implementation. Collaboration between industrial network vendors and end users is necessary to overcome initial deployment challenges. Ultimately, successful integration of SPE will depend on demonstrating tangible benefits such as simplified cabling, reduced cost, and more reliable high-speed data transmission.

Technology trends

“SPE capabilities address several industry trends and challenges, including industrial digitization and the growing demand for real-time data from in-cabinet devices. These technologies support the shift toward smart manufacturing and IIoT by enabling full Ethernet communication all they way down to the smallest components, like motor controllers and push buttons,” Passineau said.

“For example, our new EtherNet/IP™ In-cabinet Solution from Rockwell Automation takes advantage of SPE technology to streamline industrial networking with a compact, space-efficient 7-conductor flat media cable that combines power and data to reduce wiring complexity and cost.”

By using standardized Ethernet protocols, SPE can significantly reduce the need for fieldbus protocol converters and promote seamless device integration. These technologies enable greater transparency and control at the edge of the network, paving the way for smarter, more responsive industrial operations. The advantages are valuable in space-constrained environments and where legacy systems limit network performance.

Impact on smart manufacturing

Passineau said that SPE is gaining traction in industries focused on automation, data collection, and safety-critical operations. Key adopters include the automotive sector, industrial automation and material handling.

In manufacturing, SPE is being adopted for factory automation, robotics, and smart sensor networks, where its compact cabling and Ethernet compatibility improve flexibility and reduce downtime.

“The impact on manufacturing operations includes streamlined network architecture, improved access to data, and faster commissioning of devices. This leads to more agile, data-driven decision-making, better predictive maintenance, and enhanced overall equipment effectiveness (OEE),” Passineau said. “As more devices become SPE-compatible, industries can expect easier integration, lower total cost of ownership, and increased system scalability.”

Harvesting the innovations

SPE is engineered to overcome several longstanding challenges in industrial networking, including the five outlined below.

- It addresses the need for compact, cost-effective wiring in space-constrained and high-density installations, replacing bulky multi-pair cables with a single twisted pair.

- Another challenge is the lack of unified communication protocols across layers of industrial systems. By enabling full Ethernet access from the control system to individual devices and components, SPE helps unify IT and OT networks, reducing integration complexity.

- This technology helps solve the need for higher data bandwidth and deterministic performance in time-sensitive applications, something traditional infrastructures struggle with.

- Their plug and play design also aim to reduce engineering time during system design, commissioning, and maintenance.

Anticipated impact

The adoption of Single Pair Ethernet is expected to significantly transform industrial networking and automation.

“One major impact is the simplification of network architecture—offering a unified Ethernet-based framework from the enterprise level down to in-cabinet devices. This reduces wiring complexity, enables faster commissioning, and minimizes system integration challenges,” Passineau said. “The increased access to real-time data from cabinet components allows for more effective predictive maintenance, leading to higher uptime and operational efficiency.”

He added that, economically, the reduction in cabling costs and installation labor can lead to substantial savings in large-scale deployments. Over the long term, these technologies will facilitate smarter factories and process plants by enabling edge intelligence and seamless data flow. As standardization and device support grow, the impact will expand, making digital transformation more accessible to all levels of industry.

“SPE is designed to be a simple and low-cost way to connect devices at the industrial automation edge to the network. A significant number of collaborative efforts have already been completed to make sure that SPE technology adheres to open IEEE international standards. Work is currently ongoing to ensure SPE connector standardization extends across a variety of industries. ” — Dr. Al Beydoun, ODVA President and Executive Director.

Industry partnerships

Single Pair Ethernet and Ethernet APL connectivity have taken serious steps forward.

According to Dr. Al Beydoun, ODVA President and Executive Director, the development and introduction of Single Pair Ethernet and Ethernet APL connectivity have taken serious steps forward.

“Following the conclusion of a global effort coordinated between leading industrial automation standards development organizations and industry partners, the Ethernet-APL physical layer specification and engineering guidelines are completed and available,” Beydoun told the Industrial Ethernet Book recently.

“Additionally, Ethernet-APL physical layer specifications for Industrial Ethernet networks such as EtherNet/IP are ready. Conformance testing processes have been created and are available as well. End users have already evaluated the technology and provided feedback, which led to the creation of Process Device Profiles for EtherNet/IP to enable easier device replacement and data standardization. Development is currently moving forward on Ethernet-APL field devices to provide users with a broad ecosystem of controllers, power switches, field switches, and devices such as level sensors and valve positioners,” Beydoun said.

Physical layer and network specifications are also currently available for the new EtherNet/IP In-cabinet Solution from Rockwell Automation. Conformance testing for EtherNet/IPTM In-cabinet Solution is available as well now that the product has launched as of May 20th, 2025. General Purpose Single Pair Ethernet (SPE) devices are already available on the market with more being added every month.

SPE and Ethernet APL benefits

Beydoun said that Ethernet-APL is Single Pair Ethernet (SPE) that uses Type A fieldbus cable and 2-WISE intrinsic safety to enable digitalization of field devices in harsh process automation environments. Standard safety and security services built on IEC 61508 and ISA/IEC 62443 can be utilized with Ethernet-APL such as CIP Safety and CIP Security for EtherNet/IP. The digitalization of process plants with safety and security measures allows end users to access multiple process variables, speed up device commissioning, and to allow for remote device monitoring. Device vendors are also able to combine different types of sensors now into one device that can be connected to the network via SPE.

Ethernet-APL and other types of SPE such as the EtherNet/IPTM In-cabinet Solution can allow for reduced installation times via reduction in wiring that also provides sustainability benefits. Additionally, Ethernet-APL and SPE allow for connection of more field devices to the network enabling predictive maintenance, automated topology mapping and asset tracking, and additional diagnostic data availability.

Applications and vertical markets

He added that hybrid sectors such as food and beverage and consumer packaged goods, discrete sectors such as warehouses, and process sectors such as chemical plants are showing interest in the benefits of general purpose SPE, Ethernet-APL, and the EtherNet/IPTM In-cabinet Solution. General purpose SPE offers solutions such as RFID tracking on conveyors in warehouses, airports, and packaging lines, Ethernet-APL offers a robust method to connect to devices in hazardous areas or devices that are located far from a Distributed Control System (DCS) or controller, and EtherNet/IP In-Cabinet allows for motor controllers and starters to be connected via SPE.

“The impact of SPE on manufacturing operations is significant since it opens the door to using the latest Artificial Intelligence (AI) models to optimize macro-operations by identifying issues such as excessive vibrations, stoppages, and energy usage,” Beydoun said. “Additionally, instead of having to physically chase down individual wires, issues can be more quickly identified and resolved due to device level diagnostics.”

Addressing engineering challenges

SPE is designed to be a simple and low-cost way to connect devices at the industrial automation edge to the network. A significant number of collaborative efforts have already been completed to make sure that SPE technology adheres to open IEEE international standards. Work is currently ongoing to ensure SPE connector standardization extends across a variety of different industries as well. SPE will unlock additional data about processes and device health enabling controls engineers to better manage operations whether they are onsite or not.

SPE will also reduce the need to manage multiple different types of networks within a plant by allowing Industrial Ethernet to reach devices that were traditionally too small, too far, or required too much bandwidth.

“SPE will usher in a new era of productivity in industrial automation by allowing for connection of more devices than ever before to the network. The new devices can be very simple and small such as contactors and push buttons that the EtherNet/IPTM In-cabinet Solution can connect to, they can be located up to 1,000 meters away allowing Ethernet-APL to reach them, or they can be non-traditional devices such as cameras connected via general purpose SPE,” Beydoun said.

Cameras provide a good example of how SPE can enable digitalization by utilizing AI to detect if a worker isn’t wearing the appropriate type of Personal Protective Equipment (PPE) or to detect defects in products such as electronic devices, cosmetics, or food products. SPE can also help young people who are familiar with Ethernet technology to be able to use their education and training to the fullest in factories and plants of the future.

White Paper from Single Pair Ethernet System Alliance

White Paper from Single Pair Ethernet System Alliance

A new “Single Pair Ethernet (SPE) System Architecture” white paper provides extensive information on use of Single Pair Ethernet and Ethernet APL. Below are the conclusions of the white paper, and how they see the technology rolling out.

“SPE offers compact, cost-efficient and lightweight cabling with data rates of up to 1 Gbit/s over 1000 meters. It reduces the need for gateways, simplifies installations and enables seamless communication using standard Ethernet protocols – from the cloud to field-level sensors and actuators. This optimizes complex data provision and simultaneously transmits energy via Power over Data Line (PoDL). SPE offers sophisticated security functions, is standardized, scalable, interoperable and ideal for IIoT and Industry 4.0 applications. Products that are already available make SPE ready for use, even for time-critical applications.”

“SPE is becoming increasingly standardized and is expected to replace traditional bus systems such as CAN. It plays a key role in industries, IIoT, and smart buildings by providing simple connectivity for sensors and actuators. By 2030, an increase to an estimated 50 million installed nodes in factory automation and 12 million in buildings is expected. Performance and range improvements will further drive adoption.”

View White Paper –> (www.singlepairethernet.com)