TechnologyJuly 10, 2018

The IIoT and evolution of smart manufacturing

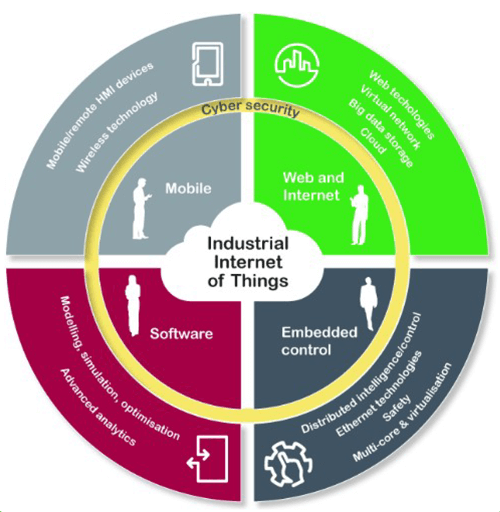

The potential of the IIoT lies in its ability to link automation systems with enterprise planning, scheduling and product lifecycle systems. This article analyses how this can be implemented across the complete enterprise value chain in order to enable greater business control.

THE INDUSTRIAL INTERNET OF THINGS (IIoT) is often presented as a revolution that is changing the face of industry in a profound manner. In reality, it is an evolution that has its origins in technologies and functionalities developed by visionary automation suppliers more than 15 years ago. As the necessary global standards mature, it may well take another 15 years to realise the full potential of IIoT. Over this period of time the changes to the industry will be far reaching.

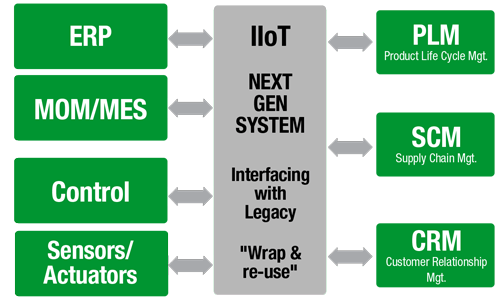

The good news is that end users and machine builders can now leverage their existing investments in technology and people while taking advantage of available new IIoT technologies. Introducing IIoT solutions using a “wrap & re-use” approach, rather than a “rip & replace” approach will enable greater business control. In addition, this measured approach will drive the evolution towards a smart manufacturing enterprise that is more efficient, safer, and sustainable.

The emergence of the IIoT megatrend has created both hope and confusion among stakeholders responsible for operating industrial plants. Much of the early hype is focused on the impact of technological advancements on existing automation platforms.

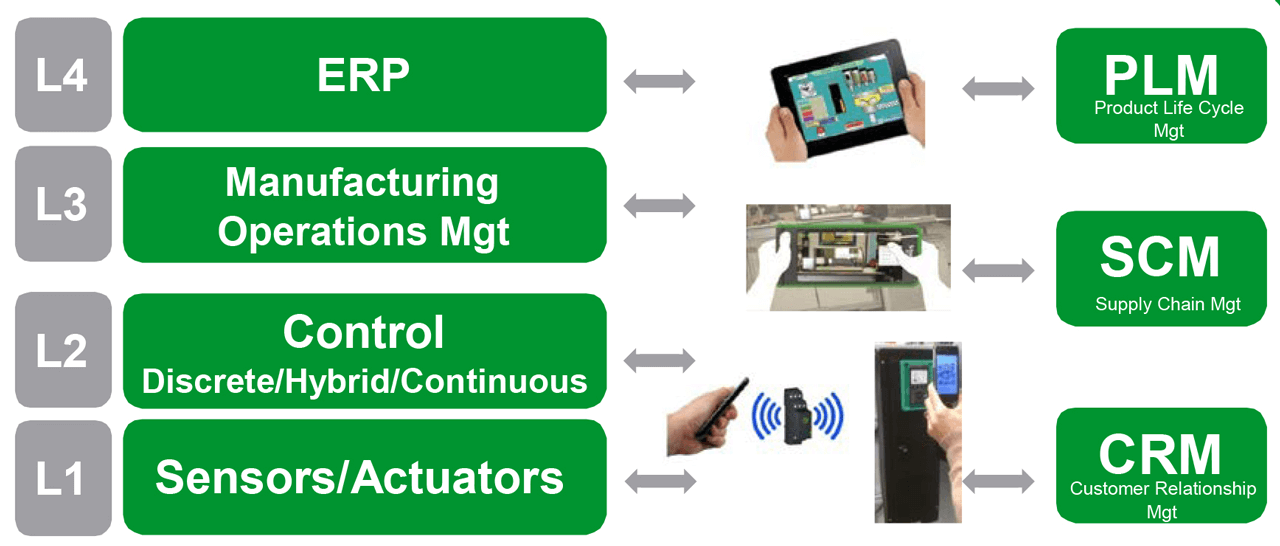

However, one of the challenges in understanding the potential of IIoT is the very large scope of applications. In the area of smart enterprise control, for example, we will see self-organizing machines and assets that enable mass customization and lot sizes of one. In the realm of asset performance, the collection and analysis of data from increasing numbers of cost-effective and intelligent sensors will increase business performance and asset uptime. A new generation of “augmented” workers will leverage cutting edge technologies, including mobile devices and augmented reality. With easier access to information across the enterprise, their work becomes simplified and production systems grow more profitable.

Some of these changes can be implemented in the short to medium term, others will require a gradual evolution with end users and OEMs incrementally adding functionality to their existing legacy systems as new international IIoT standards are established.

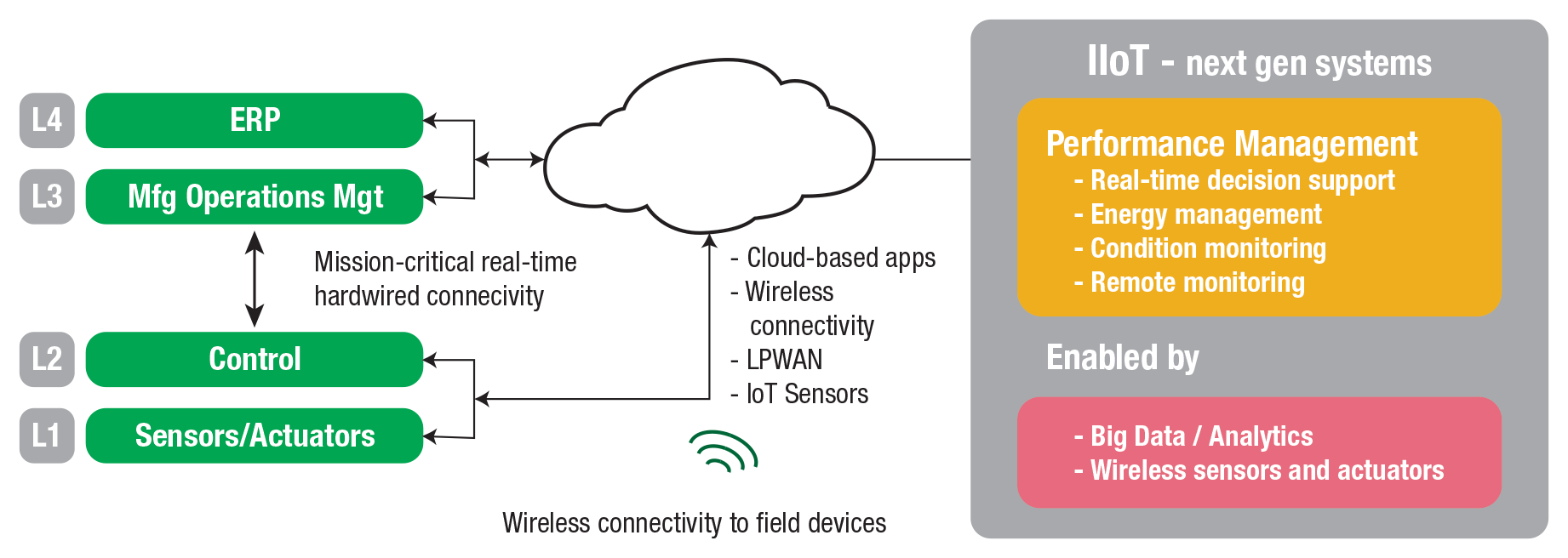

Asset performance accelerates the adoption of new performance management applications leveraging big data and analytics, and cost-effective wireless technologies.

Definitions

The IIoT vision of the world is one where smart connected assets (the things) operate as part of a larger system or systems of systems that make up the smart manufacturing enterprise. The “things” possess varying levels of intelligent functionality, ranging from simple sensing and actuating, to control, optimisation and full autonomous operation.

The smart manufacturing enterprise is made up of smart machines, plants and operations all of which have higher levels of intelligence embedded at the core. The linked systems are based on open and standard Internet and cloud technologies that enable secure access to devices and information. This allows “big data” to be processed with new, advanced analytics tools and for mobile technologies to drive greater business value. This, in turn, enables improvements to efficiency and profitability, increased cyber security and innovation.

Holistic enterprise control breaks down enterprise silos and facilitates better business control.

Smart manufacturing enterprises

While the long term impact of IIoT is at times difficult to predict, three distinct operational environments will set the stage for the smart manufacturing enterprise to emerge.

Smart Enterprise Control: IIoT technologies will enable tight integration of smart connected machines and smart connected manufacturing assets with the wider enterprise. This will facilitate more flexible and efficient, and hence profitable, manufacturing. Smart enterprise control can be viewed as a mid-to-long-term trend. It is complex to implement and will require the creation of new standards to enable the convergence of IT and OT systems.

Asset Performance Management: Deployment of cost effective wireless sensors, easy cloud connectivity (including WAN) and data analytics, will improve asset performance. These tools allow data to be easily gathered from the field and converted into actionable information in real time. This will result in better business decisions and forward-looking decision making processes.

Augmented Operators: Future employees will use mobile devices, data analytics, augmented reality and transparent connectivity to increase productivity. As fewer skilled workers are left behind to man core operations due to a rapid increase in baby- boomer retirement, younger replacement plant workers will need information at their fingertips. That information will be delivered in a real-time format that is familiar to them. Thus the plant evolves to be more user-centric and less machine-centric.

While these three areas are closely related and share many inter-dependencies, they also have differences. For example the time scales on which they can be implemented and the kind of automation market segment that they address are not the same.

There are two other areas, collaborative robotics and 3D printing, which are also pertinent to the discussion surrounding IIoT, but these are not discussed in this paper as they are specific technologies that cannot be applied to all manufacturing enterprises.

Augmented operators are more productive because they receive the right information at the right time.

Smart enterprise control

One of the biggest potential benefits of next generation IIoT systems is the breakdown of enterprise silos. The technologies will allow for closer integration of production systems and ERP systems, Product Lifecycle Management (PLM) systems, Supply Chain Management and Customer Relationship Management (CRM) systems. Today, these systems are managed somewhat independently of each other, which prohibits a holistic view of the enterprise. It is believed such a holistic approach could facilitate an enormous efficiency gain of up to 26 percent for enterprises.

Smart enterprise control does not mean replacing current automation systems with completely new systems. Instead, it implies the connection of current automation systems with enterprise, lifecycle and value chain systems. This optimises the entire manufacturing enterprise and enables a much greater degree of business control.

Tighter integration will allow enterprises to not only be more efficient, but also more profitable thanks to greater flexibility and responsiveness to volatile market conditions. The notion of control will expand from the real-time control of a physical parameter, to the right-time control of the whole business, including both physical and non-physical parameters. Benefits will include the ability to enhance protection against cyber threats, more innovation, and the ability to better manage safety, performance and environmental impact.

Examples of smart enterprise control include the following: mass customisation and lot sizes of one, reducing the size of product recalls, detection of defective products earlier in the manufacturing process and modification of product design to eliminate root causes, modification of production planning based on weather forecasts, modification of production plan/recipes based on the spot price of raw materials.

Asset performance

Many new skills will be required to design and operate IIoT systems.

Asset performance management applications such as energy management and predictive maintenance are not new to industry, but have had limited uptake due to the cost of implementation. The costs of physical connectivity (the cost of cabling to the sensors) and logical connectivity (integration with existing systems) have been prohibitive. Wireless IP connectivity and cloud-based architectures now overcome these cost barriers. In addition, a new generation of simple, small and low cost sensors is emerging; As a result, next generation IIoT systems will deliver innovative solutions in the area of asset performance.

Consider the example of condition-based monitoring/predictive maintenance. Much money is wasted maintaining equipment that doesn’t require maintenance, or by neglecting equipment that subsequently fails and causes unanticipated production downtime. Solutions such as condition-based monitoring do exist today, but uptake has been limited by cost. Next generation IIoT systems promise to significantly reduce implementation costs for such solutions.

Augmented operator

The use of mobile Human Machine Interface (HMI) technologies such as smart-phones, tablets and wearables, combined with IP-access to data and information (analytics and augmented reality) will transform the way operators work. Portable wireless devices will expand their capabilities and technologies such as dynamic QR codes will improve the operator experience and render the “augmented” operator more productive.

Today, operators only have access to information from automation systems. Tomorrow, augmented operators will access information from all of the needed enterprise systems and will manage not just process performance/efficiency, but also process profitability.

Barriers to adoption

Several barriers will need to be overcome before next generation IIoT systems are widely adopted across manufacturing industries. These include the establishment of industry standards around IIoT, cyber security protection, and workforce adaptation to new sets of skills.

Standardisation: Standards are required to allow smart connected products, machines and assets to interact in a transparent fashion. This goes beyond the simple communication protocols, and involves the creation of standard semantics and mechanisms that will allow smart devices to discover each other and interoperate. Some standards, such as PackML, do exist in this area, but they are incomplete and do not cover all aspects of manufacturing. The Industry 4.0 and the Industrial Internet Consortium initiatives are currently addressing the question of standardisation.

Cyber security: The advent of the IIoT is accelerating the need for cyber security for control systems. The complexity of IIoT means that cyber security must be designed into the components in the automation system.

The adoption of industrial security standards with certification will be essential to the advancement of IIoT because it will ensure the security not just of individual assets but also of the larger systems and systems of systems. These certifications will play a role similar to those which occur in the realm of safety certifications. Adherence to the certification means that the elements of a system hold the key security building blocks. The elements are combined in a secure way by security certified teams and are operated as a secure system by security trained operators.

The key to security certification is consistency and applicability. Worldwide, the IEC62443 series of security standards covers all elements of security from product development through to product features, system features, delivery and operation. It is important to note that while today some independent bodies offer certification to IEC62443, IEC itself has not yet endorsed any of these bodies for IEC62443 certification.

Complementary to IEC62443 security standards, existing industrial standards are also evolving to be more secure. DNP3 has evolved to DNPV5 to add security, OPCUA offers significant security enhancements, Modbus is evolving to Modbus Secure, EtherNet/IP is becoming EtherNet/IP Secure. In addition many IIoT systems are adopting security features derived from existing IT standards such as HTTPS, certificates, and encrypted/authenticated protocols.

Worker competencies

The skill-sets required to design and operate an IIoT-based system are somewhat different from those needed to run a classical automation system. A significant amount of re-training will be required for existing operators and maintenance staff to manage such systems. The good news is that the IIoT systems will use technologies that are familiar in everyday life, and the new generation of young operators will have no problems adapting to this new approach.

The main challenge for automation suppliers will be to design and supply diagnostics/debug tools that can rapidly identify the root cause of problems. This will ensure that a malfunctioning or downed system can be restored quickly.

Information driven architectures

As smart manufacturing enterprises start implementing smart enterprise control and asset performance systems managed by augmented operators, automation vendors will respond by implementing IIoT at all levels of the automation hierarchy. This will allow easy integration with next generation IIoT systems. In addition, with the increasing power of embedded electronics, connected intelligence will migrate down to the lower levels of the automation hierarchy – to the control level and to the sensors and actuators.

As a result, operations technology (OT) systems will merge with information technology (IT) systems and the automation hierarchy will evolve to be a much flatter and more information-driven architecture. Since the future implications of this are still unclear, the technologies and architectures employed must be flexible, adaptable to change and capable of integrating with legacy systems. The monolithic, single-source, hierarchical approaches and architectures of the past will not work in the future.

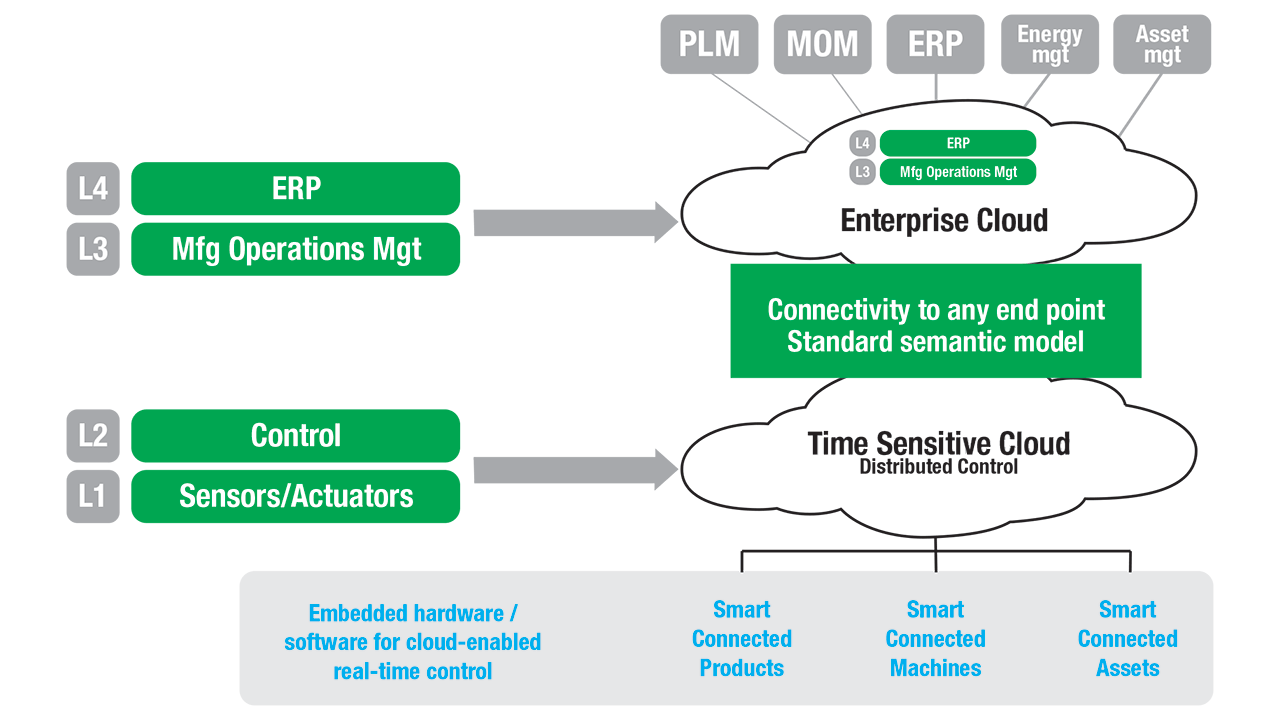

The architecture consists of two distinct layers. Information flow across both layers will be transparent using semantics and discovery mechanisms based on industry standards. Both layers are explained below.

A time-sensitive layer for real-time deterministic control. This layer is often referred to as “fog” or “edge”. However using the term “time-sensitive IP-based” for this layer underlines the fact that the technologies included in this layer are fundamentally the same IIoT technologies used in the enterprise cloud layer, but are optimised for real- time deterministic communications.

The OT devices that comprise this time sensitive layer (sensors, actuators and controllers) will be cloud-ready and capable of interfacing transparently with the IT business systems of the second layer. Those same devices will also have a high degree of intelligence. Consider the example of control valves with embedded temperature, pressure and acoustic sensors. They are able to operate autonomously using set points from the enterprise, determining their own needs for preventive maintenance, and informing the maintenance department of their condition in a timely manner.

A cloud enterprise layer where enterprise systems (ERP, MOM, PLM, SCM, CRM, etc) and next-generation functions including asset management and energy management interoperate with each other and with the time-sensitive, cloud-ready systems.

The use of the term cloud above refers to the technologies used, rather than the physical location of the infrastructure. There are many reasons to believe that, in the industry automation business, “on-premise” clouds (commonly referred to as “edge”), will be the most widely used architecture.

Centralised vs. distributed control

The arguments for highly centralised redundant control systems versus highly distributed control systems have gone on for many years. Proponents of each architecture fiercely defend their position with valid arguments.

The advent of IIoT does not resolve this debate. On the one hand, the use of cost-effective embedded electronics in field devices argues for more distribution of intelligence and control. On the other hand, the high speed IP-connectivity of field devices enables a more centralised architecture where all the sensors and actuators are connected to a highly redundant and powerful multi-core processor located in a secure on-premise data centre.

Today an application is programmed with a particular hardware target in mind, for example a PLC. Tomorrow, an application will be programmed independently of the underlying automation hardware, and the system will distribute the application transparently to the hardware, configuring all communication mechanisms automatically.

This approach will allow users to choose either a highly centralised or distributed architecture, or a hybrid approach based on their specific requirements and concerns. A Distributed Control Standard (IEC 61499) exists that will facilitate this work and which can be used as the basis for an IIoT distributed control standard.

The distribution of intelligence into the field will allow smart connected products and smart connected machines to publish important information in a standardised format. Intelligent brokers will make this information available in a transparent manner to the systems and applications that require it. This approach will overcome one of today’s current challenges: the location of information is unknown and therefore cannot be discovered or exploited without custom programming.

Networked automation architectures

Networks will see an ongoing exponential increase in smart connected devices. Devices will exploit a time-sensitive IIoT/Ethernet backbone to interoperate with each other and with devices residing in other enterprise systems.

An example of the sheer number of connected devices can be seen at the Torresol Energy Gemasolar solar power plant where 4000 Schneider Electric PLCs/drives are connected via Ethernet to control the displacement of solar mirrors.

The large number of networked devices presented many new challenges not only in the area of network management and performance but also in the area of managing the overall configuration of the distributed control system and its application software.

Implementing large networked systems with today’s classical automation techniques is complex. Tomorrow’s IIoT-based automation systems will require a new approach to simplify the design, management, and maintenance of networked automation architectures.

IIoT is often described as a revolution that will change life as we know it. In the areas of consumer goods, building management and others there is some truth to this. However, across industry, IIoT will be applied more slowly as different sectors of the industrial markets evolve their specific needs and address their unique challenges.

Conclusion

While the interest in IIoT has reached fever pitch, there are several reasons IIoT should be seen as an evolution, not a revolution. End users have invested hundreds of millions in industrial automation and control systems and are absolutely unwilling to invest hundreds of millions more to replace those systems with new technologies.

Even if a valid business case could be made for system “rip and replace” due to the benefits of IIoT, end users would nevertheless still resist the change because of the increased risk of downtime and associated costs.

In addition, visionary automation suppliers like Schneider Electric and select end users have been quietly working towards this goal for over 15 years. The concept of embedded web servers and the use of Ethernet as a real-time control network to allow ubiquitous access to information “transparently” from anywhere within the enterprise was first brought to the market by Schneider Electric in the late 1990s. Presented as “Transparent Factory”, the concepts are clearly echoed in the IIoT story of today.

Advances are still required in the area of standards to fully realise the potential of IIoT. Nevertheless, despite the slow adoption rate, the impact of IIoT on manufacturing will be far- reaching. Suppliers and users must start adopting IIoT technologies in their products and operations if they wish to remain competitive in the marketplace. The good news is that technological maturity is such that businesses and enterprises can now introduce IIoT solutions by phasing in new technologies that shift their physical infrastructure base over time.

The cost of connected sensors is dropping rapidly, open IP-based protocols are gaining traction at an accelerating rate and the adoption of cloud-based solutions is becoming a reality. Suppliers like Schneider Electric have the expertise to work with manufacturing companies to apply IIoT technologies to production systems and drive the evolution toward a smarter manufacturing enterprises that are more efficient, safer and more sustainable.