TechnologyMay 18, 2023

Three ways manufacturers can embrace Industry 4.0

Before Industry 4.0, OT devices and systems were “air-gapped” to isolate them from risk. That is not possible today. Industrial switches, media converters and wireless routers must feature robust, DoD-compliant layer 2 and layer 3 security that helps manage network traffic at scale.

Global supply chains are buckling under the strain of unprecedented demand and constricted logistics capacity. Added to skyrocketing inflationary forces, it is no wonder that an increasing number of OEMs are embracing Industry 4.0 to bolster enterprise efficiency by making their manufacturing more aware, predictive and autonomous.

The shift from Industry 3.0 to Industry 4.0 involves the convergence between information technology (IT) and operational technology (OT). Connecting OT systems to an IT network allows a more detailed view of individual equipment and creates a comprehensive view of the entire ecosystem, simplifying management and operation.

Besides allowing machines to be largely operated autonomously without human supervision, Industry 4.0 creates higher value when data collected from intelligent sensors and actuators connected to equipment leads to better decision making, as well as to the “learning” that is now possible with artificial intelligence (AI) and machine learning (ML). These benefits are compelling and explain the explosion of interest in Industry 4.0.

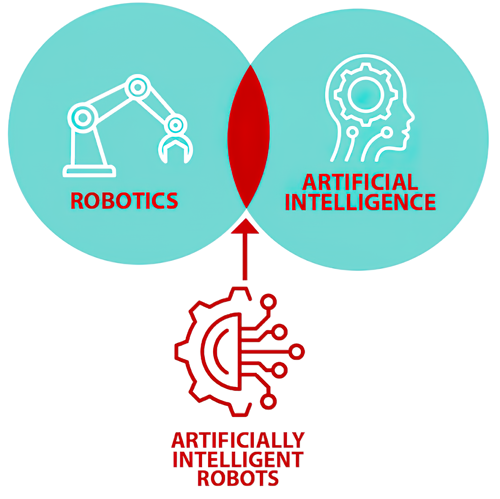

One promising category for AI is providing intelligence for autonomous robotics.

For OEMs, Industry 4.0 unlocks actionable data throughout the plant and beyond, improving operational awareness in manufacturing and maintenance processes. For example, automated assembly systems that once operated in data silos can connect to IT databases from purchasing, compliance and customer service departments, or to data from a Manufacturing Execution System (MES) and Enterprise Resource Planning (ERP) software to identify trends, detect bottlenecks and take advantage of emerging opportunities.

As another example, analyzing big data collected from sensors on the factory floor provides real-time visibility of manufacturing assets to facilitate predictive maintenance to minimize costly downtime. In this instance, machine learning algorithms detect and target faulty parts before they wear out, rather than wait until repair work is more expensive.

Besides gaining insights from a local shop floor, warehouse or assembly line, Industry 4.0 provides visibility into supply chains thousands of miles away where an OEM’s suppliers may be located. OEMs can be informed of where their assets are in the supply chain so they are in a better position to fulfill customer deliveries in a timely fashion.

Historical supply chain data could be sent to the cloud for analysis, helping to create predictive models and develop condition-based alerts. If a delay is detected, software will alert the OEM so that it can pivot in strategy.

Applying Industry 4.0

The Industry 4.0 megatrend is now being applied across a wide swath of industrial sectors where it is benefitting discrete and process manufacturing, petrochemical, mining, agriculture and other diverse segments poised for unprecedented growth. Antaira has identified three ways to embrace this exciting paradigm shift:

- Artificial intelligence

- Network connectivity

- Device cybersecurity

Artificial intelligence

AI is the simulation of human intelligence processes by computers to analyze data for correlations and patterns, and the use of these patterns to make accurate predictions about future states. AI is all around us. From agriculture applications that detect imperfections in fruits and vegetables during harvesting processes, to autonomous construction and farming machinery that use GPS technologies to navigate over predefined routes. Industry 4.0 uses AI to analyze sensor data to track equipment usage, improve workflows, streamline logistics, increase safety and achieve higher overall efficiency across OT and IT operations.

One promising category for AI is providing intelligence for autonomous robotics. Autonomous robots are increasingly finding their way into manufacturing operations. AI-driven “cobots” reduce labor costs and increase productivity simply by continuously working around the clock without fatigue or breaks. In addition, safety is improved in hazardous environments, and insurance and injury leave costs are significantly reduced.

As AI continues to advance, problem-solving and learning analytics will enable autonomous robots to be responsive to their environment with minimal or no human feedback. To give you an idea of what that means, think of the thousands of manned forklifts operating today in warehouses and port terminals. Forklifts are labor-intensive, expensive to maintain and dangerous. As an alternative to a forklift, let’s say AI is applied to an automated guided vehicle (AGV). Freight is picked using a barcode reader. The AGV then automatically reroutes itself with the freight on board to the best path through the warehouse using wireless routers and industrial switches. Sensors assure no collisions occur with obstacles or employees.

Potential for autonomous robots using these devices are virtually endless. In the agricultural market, for example, Antaira industrial Ethernet switches are now being deployed in robotic fruit picking devices that can delicately grasp a single strawberry without bruising it. Antaira is also connecting and transmitting data in robots capable of automatically targeting and eliminating weeds using thermal energy while rolling through agricultural fields. Also, Antaira industrial-managed Ethernet switches are incorporated in an upgrade kit that transforms trench excavation equipment from the likes of Caterpillar, Volvo, Hitachi, Deere and Komatsu into autonomous robots operated remotely on a laptop.

Network connectivity

With the exponential growth of Industry 4.0 technologies, operational networks are continually going through expansion processes, requiring the same type of bandwidth allocations and infrastructure support as the enterprise network counterparts. Furthermore, as Industry 4.0 is trending toward an increased focus on AI for big data analytics and cloud computing for process and control information collection, connectivity and connection points have become a critical piece in the industry 4.0 puzzle.

With the exponential growth of Industry 4.0 technologies, operational networks are continually going through expansion processes, requiring the same type of bandwidth allocations and infrastructure support as the enterprise network counterparts. Furthermore, as Industry 4.0 is trending toward an increased focus on AI for big data analytics and cloud computing for process and control information collection, connectivity and connection points have become a critical piece in the industry 4.0 puzzle.

Ethernet is the technology of choice for operational networks thanks to its standardization, versatility and low cost. An all-IP Ethernet infrastructure also helps to meet the imperatives of cybersecurity, determinism and system reliability. Thanks to these advantages, legacy technologies such as analog fieldbus systems are migrating to Ethernet, allowing for communications with modern technologies.

Ethernet thru TCP/IP-based communications now range from AI cloud-based processes to legacy bus systems that can interconnect the smallest application using just one twisted wire pair. In a recent development, the IEEE published a standard for 10 Mbit/s (IEEE 802.3cg) important to Industry 4.0 that allows transmission distances up to 3,280 feet, therefore holding the potential to replace virtually all fieldbuses currently in use.

One of the main components underpinning Ethernet connectivity is the Ethernet switch. Managed and unmanaged Ethernet switches are staples of Industry 4.0 architectures with the ability to transmit data between connected devices and wider networks in a way that is secure from outside threats.

While a basic Ethernet switch simply filters and forwards network packets from one networking device to another, industrial switches offer much more.

Device cybersecurity

The tools and software of Industry 4.0 are revolutionizing manufacturing. We are now seeing the Smart Interconnected Gigafactory that can monitor and control every facet of intelligent production processes. But just as these new technologies have created the opportunities for optimization, they have also introduced new risks and security threats, creating a completely different threat vector than PC-based networks.

Industry 4.0, for all its benefits, makes “Industry” an appealing target for cyberattacks. The expanded attack surface gives bad actors the opportunity to move laterally across a network, jumping across IT and OT systems for industrial espionage, intellectual property theft, IP leakage or even production sabotage. For this reason, cybersecurity best practices must be acknowledged as one of the pillars to a successful Industry 4.0 strategy.

Adopting this risk-based security mindset includes:

- Recognizing that every connected device represents a potential risk, therefore, you must maintain a real-time inventory of all OT assets and monitor the network for devices that have been added without authorization.

- Identifying and monitoring who can access devices. Implementing secure password policies that prioritize length over complexity will help prevent unauthorized network access.

- Taking a security-first approach to the deployment of any new connected devices. Require new devices go through verification before they can gain access to the network and proceed to communicate with other devices.

- Performing real-time vulnerability assessments and risk-based prioritizations to spot potential threats. Regularly scanning the network will identify suspicious communications or content, malicious software, improper access and any signs of access control manipulation.

- Fixing any outdated systems, unpatched vulnerabilities and poorly secured files.

- Implementing multi-factor authentication whenever possible.

- Segmenting networks and restricting host-to-host communication pathways.

- Ensuring that device suppliers commit to regular security and software patches and audits.

- Involving, not just informing, the C-suite of the cybersecurity process.

Cybercriminals attack the low-hanging fruit, meaning they will go looking for easy targets and then work their way deeper inside the perimeter.

In the case of Industry 4.0, the “low-hanging fruit” are your connected OT devices, especially those with decades-long life cycles, an inability to patch systems due to stability concerns and a lack of basic cybersecurity features such as user authentication or encryption. This threat environment has been further heightened by device vendors jumping into the industrial market from the IT space with little background into OT cybersecurity.

Before Industry 4.0, OT devices and systems were “air-gapped” to isolate them from risk. That is not possible today. Industrial switches, media converters and wireless routers must feature robust, DoD-compliant layer 2 and layer 3 security that helps manage network traffic at scale. And your NAT routers should be able to conceal the identity of an IP address block being used on a network.

The device manufacturer you work with should give administrators the tools they need to build on existing security policies and company standards, such as an authentication, authorization and accounting mechanism that can track user activities while limiting essential controls to employees who require them.