TechnologyNovember 19, 2023

Industrial 5G boosts efficiency in real-life intralogistics

Industrial 5G is changing the way companies make decisions, manufacture products and maintain factories. Thanks to Industrial 5G, the MF-K factory has become an example that has proven that companies will even further increase efficiency and productivity as they implement real-world applications.

The Siemens production facility for Manufacturing Karlsruhe (MF-K) incorporates Industry 4.0 in a double sense.

On the one hand, the factory produces a wide variety of key components for automated and digitalized manufacturing processes. At the same time, MF-K follows the approach of “using what we sell”. Products from their own portfolio are used daily – proving that private Industrial 5G networks already enable increased efficiency and flexibility today.

Today’s manufacturing is subject to VUCA (Volatility, Uncertainty, Complexity, and Ambiguity). This is manifested in a high number of product variants, shortened development times, and fluctuating order quantities. The exploding need for variety results in ever-smaller lot sizes. At the same time, there is a demand for customized high-quality products at the cost level of mass production.

The more unpredictable customer behavior and supply chain become, the quicker factories need to react. Fluctuations especially impact intralogistics, making agile workflows necessary. As a result, real-time information flow, flexibility, and reliable communication become the centerpiece of modern production processes – all made possible by Industrial 5G at MF-K.

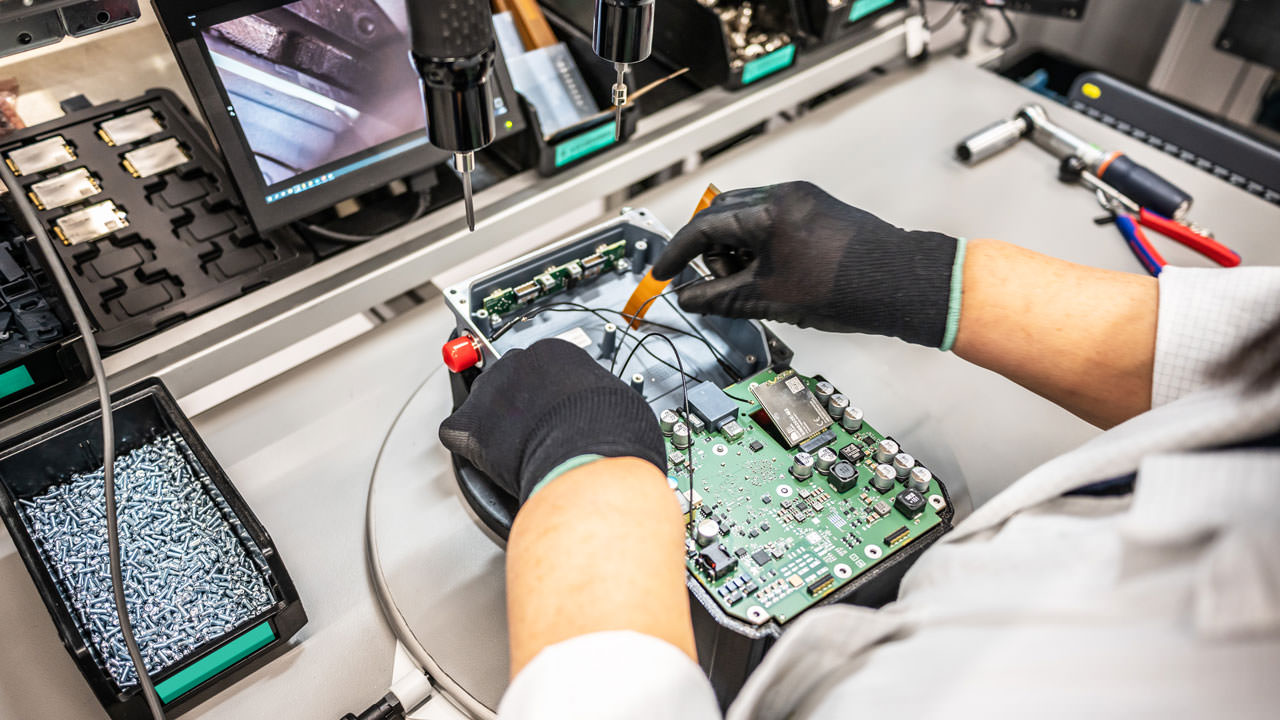

Industrial 5G routers in the making: “At MF-K, we do not only produce them, but we use them as well.”

Forming innovation through technology and humans

MF-K is located at the heart of Siemens-Industriepark Karlsruhe, Germany. Manufacture ranges from automation and process control systems to Ethernet switches, Industrial Wireless LAN devices, mobile wireless routers, and Industrial PCs. The manufacturing concept with its matrix production is based on agile and digital production processes enabled by cutting-edge technologies. However, the success of MF-K doesn’t rely on technology alone.

Its main advantage is the seamless collaboration of people and digital solutions. In 2022, the MF-K received the renowned “Factory of the Year 2021” award. One of the reasons: extraordinary adaptability and active involvement of all employees in the ongoing transformation process. This perfectly fits MF-K’s mission “it’s only through people that our digital factory becomes intelligent.”

Achieving flexible intralogistics by implementing Industrial 5G

One of the focus areas of the human-machine collaboration at MF-K is intralogistics. Typically, shuttles, AGVs (Automated Guided Vehicle), or mobile robots provide workers with exactly the required tools, raw materials, and semi-finished products – right when they need them. One of the core elements of the factory is the “matrix production in flow”. Each product can be produced on any module. For every order, the production management system autonomously chooses the next available module – a concept that has proven effective in avoiding bottlenecks, accelerating throughput, and increasing customer orientation.

“Wickie”, one of MF-K’s mobile “cobots” (collaborative robots), delivers semi-finished products – right when they are needed.

Mobile “cobots” (collaborative robots) with cuddly names support intralogistics at MF-K. They communicate wirelessly using Industrial Wireless LAN. Hence, using also 5G for this purpose was a logical step to go. The supply process was identified as an ideal area to implement 5G-driven applications in a tough real-life environment. In MF-K, Autonomous Mobile Robots (AMRs) fulfill their task on the shopfloor by moving components and semi-finished products to their relevant location. They communicate in a private 5G network.

MF-K acts as a pioneer by incorporating a private 5G network into daily work: “We’ve been producing industrial solutions for a very long time, and we know what’s needed for the future of industry. Private Industrial 5G is an essential part of this story”, states Stefan Förschner, Head of Factory Operations. “Many manufacturing companies consider establishing private Industrial 5G networks. We at Siemens believe in the new communication standard and have supported its standardization and industrial implementation by developing a corresponding portfolio. Here in MF-K, we already produce 5G routers, and we also use the private 5G infrastructure in a very early stage”, adds Stefan Förschner.

“Our private 5G network allows us to smoothly operate AMRs. MF-K has extreme requirements in terms of quality and productivity. Using a private Industrial 5G network under such demanding conditions is an excellent reference on the path to broader applications for various industries. And, of course, we are planning to expand the number of our AMRs, which will exclusively work with Industrial 5G in the future”, explains Uwe Bollinger, IT Infrastructure & IT Security Manager.

Stefan Förschner proudly presenting the Factory of the Year Award 2021.

Working with private Industrial 5G: advantages of a campus network

At MF-K, a private 5G network is implemented. Such a network is run locally at a defined location: here, it’s at a manufacturing site. It is operated by the user with an own 5G infrastructure and works with a private frequency. The MF-K uses the private 5G spectrum of 3.7-3.8 GHz that was introduced by the German government.

The private 5G infrastructure in the MF-K comprises a 5G Core and a Radio Access Network (RAN). They run on two Siemens Industrial PCs in a server room close to the shopfloor. One IPC hosts the 5G Core, which manages the entire 5G network including the RAN. The RAN is hosted on the second IPC and consists of a software-based Central Unit (CU) that manages the wireless network and the Distributed Unit (DU) that translates Ethernet into digital radio signals. Finally, the Radio Units (RU) – also part of the RAN – make the radio signal available on the shopfloor.

They are connected to the DU via fiber optics and are mounted on the ceiling in the production area. They ensure the even transmission and distribution of the 5G signal on the shopfloor. Each AMR is equipped with a Siemens 5G router, a SCALANCE MUM856-1 that connects it to the 5G network. The device was chosen because it offers a protection class of IP65 and can be mounted directly on the AMR without an additional cabinet.

“Our private 5G network with our private frequency gives us the possibility to smoothly operate AMRs without interferences from other users. We can assure that mission-critical or safety relevant applications run without any problems”, says Uwe Bollinger

Siemens is developing a complete private Industrial 5G ecosystem consisting of a private 5G infrastructure and end devices. The application in the MF-K is a first proof of the solution in a real-life production plant. “And it works just well”, says Stefan Förschner.

Manufacturing companies will benefit from Industrial 5G in a wide range of areas. With its characteristics, Industrial 5G will change the way companies make decisions, manufacture products, and maintain factories. Thanks to Industrial 5G, companies will even further increase their efficiency and productivity as real applications in the MF-K factory has proven.

Solution highlights

- Increased efficiency and productivity

- Smooth operation of AMRs without interferences from other users

- Mission-critical or safety-relevant applications run smoothly

- Smooth operation of AMRs without interferences from other users

- A secure and stable 5G network handling the high information flow and offering fast adaptability

- An agile workflow closing the gap between unpredictable delivery times and short-cycled customer demands

- The complete solution from one supplier – private 5G infrastructure, user equipment, and end devices

MF-K acting as a pioneer by

- Proving how 5G increases the efficiency and productivity of manufacturing

- Offering future Industrial 5G users a solution proven in practice

- Pushing further development and optimization of Industrial 5G

- Showing how manufacturing companies can strengthen competitive production even in high-wage countries

Manufacturing Karlsruhe (MF-K)

Difference between private and public 5G network

5G can be deployed in public or private networks. Public 5G networks are run by Mobile Network Operators (MNOs) and usually focus on providing a high bandwidth to a high number of participants, e.g., smart phones. Private 5G networks – so-called campus networks – are run locally at a defined location, e.g., a manufacturing site. They are operated by the users themselves on a private 5G frequency using an own private 5G infrastructure. The users can adapt the networks to exactly support their applications with regard to real-time behavior, reliability, or needed bandwidth.