TechnologyNovember 8, 2022

Industrial 5G implementations get closer every day

5G offers promising performance enhancements for consumer applications, with up to 20x more throughput than 4G and up to 100x more users in a single cell. But industrial applications will benefit far more from the boost in 5G performance, even though industrial applications have a different set of network requirements.

5G is starting to appear everywhere in our daily lives – on the display of your new smartphone, on billboards, in newspapers or TV-commercials, to name just a few. And although 5G offers promising performance enhancements for consumer applications – with up to 20x more throughput than 4G and up to 100x more users in a single cell – industrial applications will benefit far more.

Industrial verticals have different requirements to a network than consumers have in a public 5G network. One typical example is that industrial robots or automated guided vehicles (AGVs) communicate a low amount of data, however safety and efficiency demand really low latency and a high reliability.

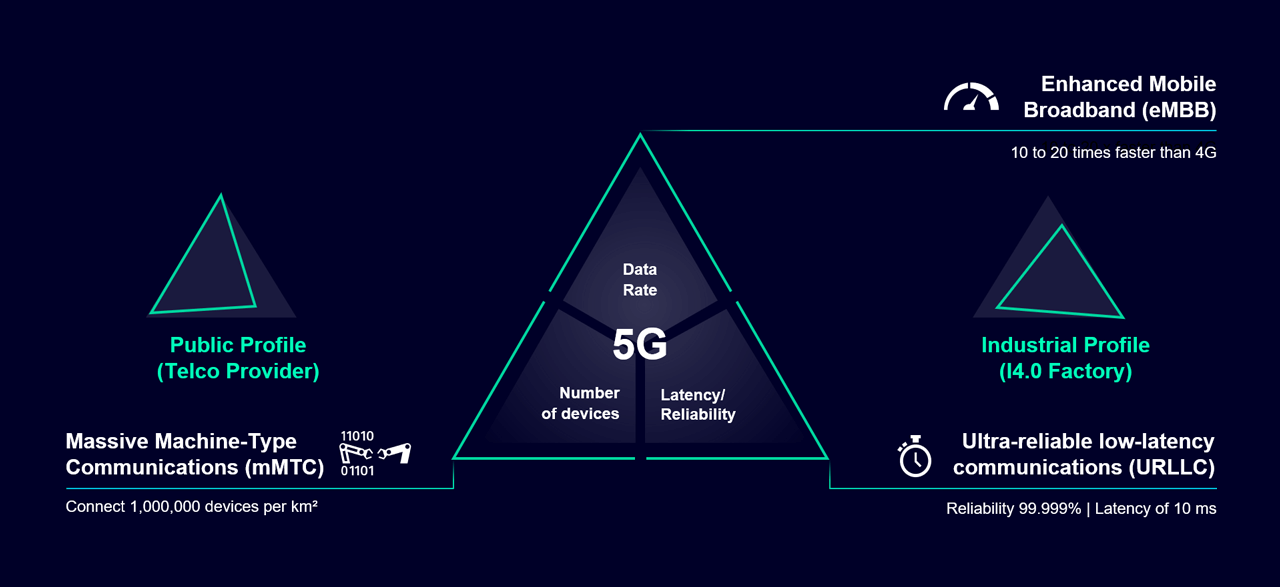

5G scenarios include Massive Machine-Type Communication, Enhanced Mobile Broadband and Ultra-reliable low latency communications.

The three scenarios of 5G

The different requirements of the industrial verticals are addressed by the three main scenarios of 5G: enhanced Mobile Broadband (eMBB), massive Machine-Type Communications (mMTC), and Ultra-Reliable Low-Latency Communications (URLLC).

The first scenario, eMBB, includes enhancements to 4G with the main objective of fulfilling data-driven use cases which require high data-transfer rates and global coverage. A typical example is the growing need for high quality, high-definition streaming of music and video to mobile devices like smartphones and virtual reality (VR) glasses.

Massive Machine Type Communications, the second scenario, focuses on having more devices in a smaller area. An use-case example are IoT-applications (Internet of Things) where a large number of connected sensors and devices send and receive data infrequently and are deployed in a small, defined area.

The third scenario is the most demanding. The typical mission-critical applications using URLLC require high reliability and low latency. Examples include mobile robots, autonomous logistics, automated guided vehicles (AGVs), and safety applications in industrial environments.

However, full implementation of these three scenarios is not possible simultaneously within the same network. A network can only be designed and configured in such a way to optimally support one use case. For example, it can offer either the highest possible data rate or the lowest possible latency. Achieving both at the same time on the same network is impossible.

Private Industrial 5G infrastructure.

Public or Private 5G?

This is where different necessary implementation approaches for 5G networks are most obvious. A public 5G network is typically set up to provide high bandwidths for e.g video streaming, and other data-intensive applications.

However, for most factory applications, bandwidth plays a minor role. The clear emphasis here: reliability and ultra-low latency in the communication network. Fortunately, private networks are an integral part of the 5G standard. They enable companies to establish their own local 5G networks and adapt them to their mission-critical applications.

For this purpose, the German Federal Network Agency (Bundesnetzagentur) has reserved part of the frequency spectrum for use in private, local 5G networks. To be more specific, a total of 100 MHz is set aside between 3,7 – 3,8 GHZ and in the mmWave band an additional 800 MHz in 26 GHz. This private spectrum can be obtained for the setup of local campus networks for a reasonable fee. A network utilizing 100 MHz of C-Band spectrum – which covers a plant from 150.000m² – would cost 5,500 Euro in total for 10 years.

This initiative from the German Federal Network Agency was the start of many countries looking into allocating private 5G spectrum for local use. Most are intended to support the roll-out of local private 5G networks in different industrial verticals. Until September 2022 in Germany, of the 249 requests for private 5G networks, 243 were granted. Most of these private 5G networks are Proof-of-Concepts to assess the benefits of 5G over existing technologies. Beside the fact that in industry typically only proven technologies are used, there are two further reasons why companies hesitate with the roll-out of Industrial 5G networks in production.

5G availability

Reliable availability of products with the right feature set is a major concern. 5G is not a single development, but comes in multiple iterations called releases. In December 2018, Release 15, the first release of 5G was completed by the 3GPP. The latest release available now is Release 17.

However, products for industrial use are not yet widely available. The main reason for this is that it takes about three years to move from a finished release to a finished product that can be used in harsh industrial environments. What’s more, most of the industry specific features are part of the newer releases – and products follow roughly three years after the corresponding release. A further concern is that the 5G user equipment ecosystem is insufficiently developed. A quick look at the number of available 5G devices results in a list of Industrial 5G routers, smartphones, and some tablets. Only recently, we’ve seen interest from vendors to equip laptops with 5G, but typical industrial devices, be it a connected screwdriver, a handheld scanner/reader, are yet to become available. However, once this has been resolved an uptake in the number of installed private Industrial 5G networks is to be expected.

Industrial 5G

And then there is another challenge: how to bring a technology driven by telecom companies into industrial verticals, where the leading technologies are Ethernet and Wireless LAN. A private Industrial 5G infrastructure solution designed to meet the needs of industrial use cases is the answer. The hardware needs simultaneously to be compact – for installation in the field – maintenance free and withstand harsh industrial environments.

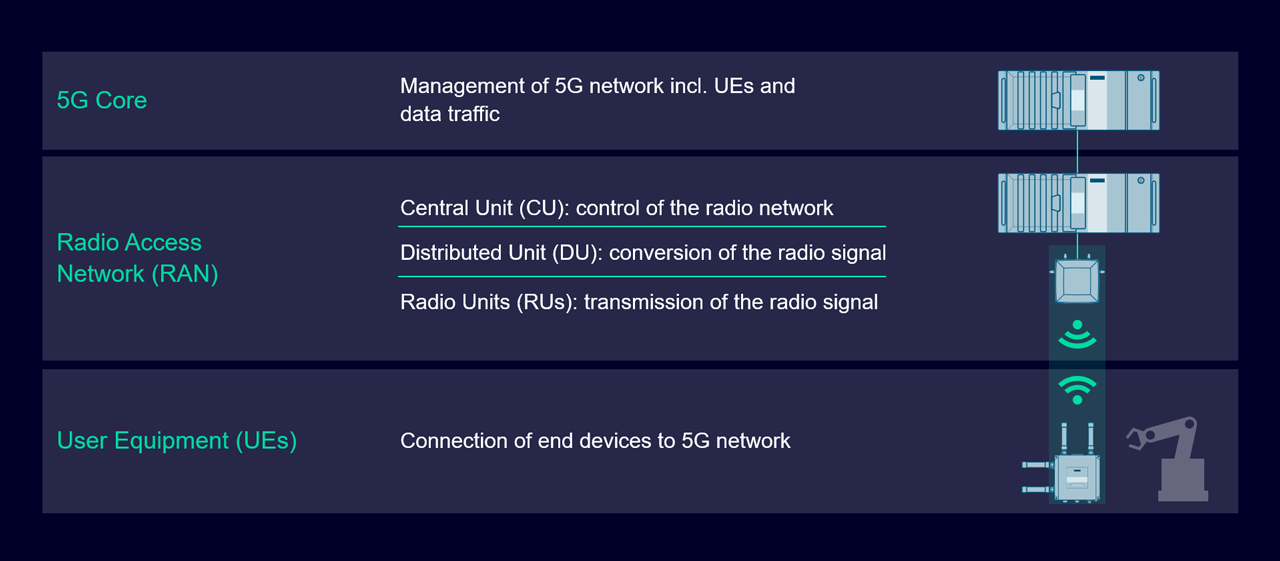

Furthermore, a simple and understandable user interface for daily operation of the network is essential. All this is currently in development and being tested by Siemens with a prototype private Industrial 5G network. The resulting network is a compact solution that runs on Siemens Industrial PCs. These Industrial PCs run both the 5G Core and a part of the Radio Access Network (RAN).

The 5G Core manages the complete 5G network including the RAN. The RAN consists of three different elements: the Central Unit (CU), the Distributed Unit (DU), and the Radio Units (RU). The CU connects the 5G Core and the DUs and provides high-level coordination of the 5G radio network. The DU converts the data packets into a digital radio signal. The RUs are the network’s radios, and they convert the digital radio signals sent and received into a radio signal.

User Equipment (UEs) is not part of the private 5G infrastructure, but connects to it like the smartphones we use every day. However, in industry it’s typically Industrial 5G-Routers like SCALANCE MUM853-1 and MUM856-1 which connect robots, AGVs and industrial devices to the local private network.

Enabling the implementation of industrial 5G

After prototype testing of our private 5G solution in the Automotive Showroom and Test Center in Nürnberg, the time came to start implementing it into a live production plant. Siemens Manufacturing Karlsruhe (MF-K) often implements innovative solutions that push boundaries.

MF-K is located in the Siemens Industrial Park in Karlsruhe, one of Germany’s most technology-driven regions. Over 37,000 m², approximately 1,000 employees manufacture 24,000 assorted products for Siemens’ global customers. Examples range from automation and process control systems to switches, Industrial Wireless LAN access points, Industrial PCs, and now Industrial 5G routers.

With so many diverse products, workers must be equipped with the tools, raw materials, and semi-finished products they need – just when they need them. Autonomous Mobile Robots (AMR) play a huge role in this. They require reliable wireless connectivity and that led to the implementation of our prototype private 5G solution. A complete setup with Core, CU, DU and RUs has been installed to provide network coverage in the areas where the AMR is active. The AMR connects to the network with a SCALANCE MUM856-1 5G router.

By testing and operating these products in our own manufacturing facility, we are developing a reliable private 5G solution to be available on the market soon and enable the industrial use cases of today and tomorrow.