TechnologyMay 18, 2023

2023 Industrial Ethernet Solutions Showcase

This Connectivity Showcase presents the viewpoints of eight industry experts. With Factory Automation Connectivity Solutions, manufacturers are collecting data in real-time to monitor, track, and optimize production processes, and improve safety, reduce downtime and increase production speed and efficiency.

Industrial Ethernet solutions are at the heart of how modern manufacturing plants are managing their networks, and provide mission-critical technology in the quest to achieve digital transformation.

In this special showcase, the Industrial Ethernet Book has reached out to industry experts to gain their insights into how Industrial Ethernet solutions are evolving to meet the needs of both engineering and information technology professionals.

“Industrial Ethernet is evolving at a fast pace. Not only is there a greater need to conform to the requirements of the IT network environment, but things are always changing and the industrial network has more and more requirements,” Mike Willett, Network Engineer, Red Lion.

Meeting the needs of control engineers and IT personnel

The evolution of technology is providing solutions at many levels

According to Mike Willett, Network Engineer at Red Lion, Industrial Ethernet technology is evolving to provide greater levels of connectivity.

“Industrial Ethernet is evolving at a fast pace. Not only is there a greater need to conform to the requirements of the IT network environment, but things are always changing and the industrial network has more and more requirements,” Willett told the Industrial Ethernet Book recently. “First of all, how we connect is evolving. We have more advanced firewalls, routers and switches now to securely connect to devices and cloud servers.”

Willett said that Red Lion’s FlexEdge can aggregate data from all over the network, perform protocol conversion for over 300 protocols so all of the devices can communicate and also push that data to a cloud server all securely over a VPN and within a firewall architecture. One device can support so many levels of connectivity within itself from networking to automation.

“We have more advanced security at the switch level to allow more devices to be connected securely and again conform to the requirements of an IT network,” Willett said. “Then, aside from the type of connectivity, the way we physically connect is evolving. The speed at which we connect is evolving. We have switches supporting gigabit and even 10 gigabit speeds now to support everything including high definition video streams and surveillance video.”

He also added that, all the way down to the power requirements is evolving. “We have advanced managed PoE switches now and devices supporting various ranges of input powers. So, Industrial Ethernet technology is evolving at a very fast rate, and it is very exciting to see this level of connectivity to support all the necessary applications.”

Industrial Ethernet megatrends

Willett said that Red Lion is seeing more advanced security features in managed switches.

“Again, as the industrial network needs to conform more and more to the requirements of the IT network, they are seeing these trends emerge,” he said. “Also, the ‘ease of use’ aspect of devices is a huge trend. Very often it will be controls engineers that need to have access to these devices and configure them. So it is very important that these devices have that ease of use factor to them. It will very often not be the IT network engineer supporting these devices.”

The N-Tron series NT5000 switches have a very granular set of security features to provide a lot of flexibility. It also has a very user-friendly web interface, so that the controls engineers that need to administer the switches can be comfortable navigating them. The switches also have a very modern look to them inside the web interface but they also have the features that IT is looking for. The devices have a very intuitive command line interface so that the more IT centric user can be comfortable navigating the switches as well.

Another trend in the Industrial Ethernet world that Willett cited is to be able to purchase a piece of hardware today, but also upgrade it as necessary to the features required via software and not have to replace hardware in the future.

For example, the FlexEdge from Red Lion has different levels of feature sets that can be upgraded in the field as necessary. This way users have that ongoing flexibility. Also, having a device that can be more of an “all in one” type of device is a big plus. The FlexEdge can also be the edge device, firewall, router; it can support a variety of automation features, protocol conversion, bringing in tag data, and support connections to various cloud servers. The trends we are seeing fit this type of criteria. It is important to have the intuitive ease of use features for controls engineers to navigate the devices comfortably, but also incorporate the IT feature sets that are required for the overall network architecture.

Key technical benefits

Key technical benefits that new Industrial Ethernet solutions are providing focus on the needs of both OT and IT personnel.

“It is all about including those network devices that fit the requirements of the IT network architecture and are comfortable for an IT centric user to support, but also have the ease-of-use aspect and be user friendly for a controls engineer to be able to support it,” Willett said. “New Industrial Ethernet solutions need to provide this. The new Industrial Ethernet needs to have a high level of security features since these networks are now connecting across the world and connecting to cloud servers and management platforms.”

New Industrial Ethernet solutions are providing that “pay as you go” structure as well. Red Lion’s FlexEdge provides different levels of feature sets that can be upgraded via software in the field. The idea of connecting anything to anything at anytime, anywhere, over fast, reliable and secure connections is a huge technical benefit of the new Industrial Ethernet solutions.

Willett said that one big challenge is being able to use all of your devices together and securely. Very often there are devices in the network that are older that have been in place for years. Also, sometimes they are communicating over different protocols. So, being able to convert legacy protocols so that all of these devices can communicate together and also be able to connect back to a modern and secure device that can handle all the outbound connections, VPN connections, and secure cloud connections is critical.

“More and more data needs to be aggregated and sent externally to your local network,” Willett said, “so being able to undertake the vast requirements is crucial to address the design of a modern industrial network.”

“We see a lot of different technologies running within factory automation solutions – everything from legacy fieldbus systems with minimal transmission rates to decentralized solutions running machine to machine communication, machine learning/AI, or digital twins in connection with technology innovations such as wireless, 5G, high performance Ethernet, hybrid connectivity, or Single Pair Ethernet (SPE),” Manuel Rüter, Principal Engineer TE Connectivity.

Fragmentation drives need for better interoperability

Moving toward a decentralized system that operates in clusters or subsystems.

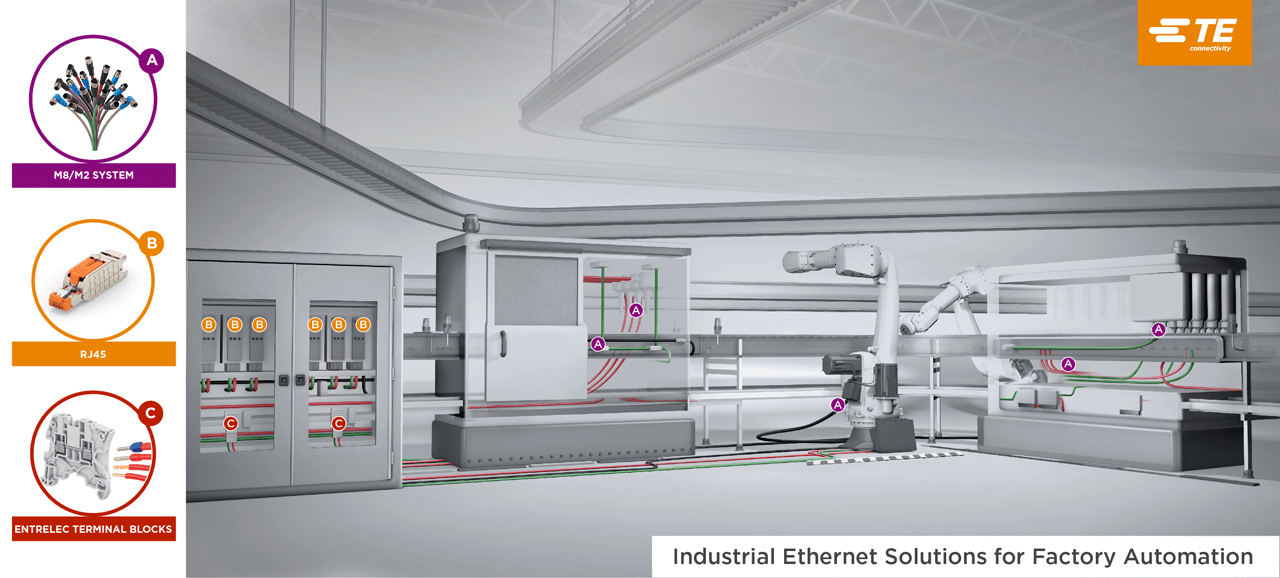

“We see a lot of different technologies running within factory automation solutions – everything from legacy fieldbus systems with minimal transmission rates to decentralized solutions running machine to machine communication, machine learning/artificial intelligence, or digital twins in connection with technology innovations such as wireless, 5G, high performance Ethernet, hybrid connectivity, or Single Pair Ethernet (SPE),” Manuel Rüter, Principal Engineer at TE Connectivity told the Industrial Ethernet Book.

“This fragmentation in Ethernet-based systems has increased the demand for stronger interoperability between and among automation solutions. To help readers understand the challenges and opportunities of this fragmented approach, it might be helpful to compare the current state to the human nervous system,” he added.

Rüter stated that today, older and current systems communicate via a centralized I/O system in the control cabinet or automation control unit – this is essentially the brain. Acquaintance technologies like terminal blocks are one of the most common solutions.

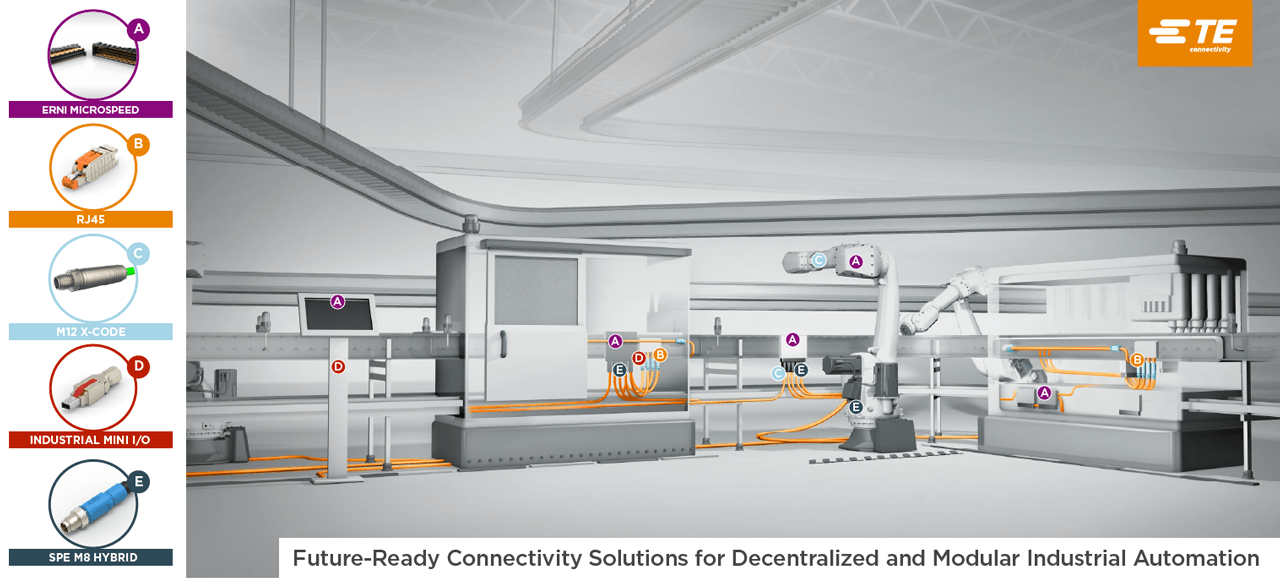

In the future, real-time communication and greater volumes of data at the field level will require a decentralized communication system that operates in clusters or sub-systems – similar to nerve endings and neurons. Most of the transactions occur directly inside these sub-systems, which requires high transmission and communication capabilities inside the device as well as significant shielding and transmission rates, which affects the innovations in board connections (example of high-performance board connection).

“Interactions and dependencies between these sub-systems are becoming more important, which has placed a higher demand on performance and bandwidth, as well as greater interest in merging the capabilities of informative technology (IT) and operative technology (OT),” he added.

Technology Trends

Rüter said that there are four trends that are having an impact on smart manufacturing operations and demonstrate the need for improved communications and interactions between IT and OT systems in the factory:

- The influence of the decentralization trend has advanced the movement toward greater modularization, which further enhances flexibility in manufacturing processes.

- Regarding topics such as material feed, predictive maintenance productivity, and better-quality information, there have been many optimizations in the material flow process, allowing manufacturers to use the parts where they need them at the right time.

- The merger of IT and OT capabilities allows manufacturers with automated guided vehicles (AGVs) to select parts directly from the office over the shop floor.

- Sensors allow manufacturers to detect even the smallest deviations in parts or process, which reduces tooling wear and material resources, and helps optimize process runtime as well as maintenance cycles and commodity flow. Modular machine elements or production areas make this concept complete and also include the possibility of shared production.

Applications focus

He added that enhancements to Industrial Ethernet technology are providing unique capabilities that can are being applied to industrial applications.

Rüter said that collaborative robots (cobots) are a good example of the enhancements made available through Industrial Ethernet technology advancements. The greatest value of cobots is that they can help free a skilled employee from the menial aspects of their job in order to concentrate exclusively on the high-value aspects.

For example, in complex device assembly requiring a deft human touch, a cobot can perform simple handling or manufacturing tasks that allow workers to focus on the parts of the job that make full use of their skills or knowledge. The goal of the industrial internet of things (IIoT) is to make processes easier and help optimize workflows.

“Camera and sensor systems are also great examples of advances in Industrial Ethernet technology. In the past, manufacturers were limited to information provided by the quality gates or the quality control behind the complete process. Now, with IIoT components, manufacturers have access to just-in-time information on each piece, including reaction time, optimizations, intervention-related quality, and efficiency – all to help reduce costs and minimize bad parts,” he said.

He added that there are three ways Industrial Ethernet solutions contributing to IIoT and enterprise connectivity.

- In the fast-paced world of production, machine-to-machine communication that allows information to be exchanged directly between the involved production areas and elements (such as robots and conveyor technology) makes it possible for manufacturers to keep up with highly complex supply and production chains.

- Sensors of any kind require processing intelligence and interpretation to provide data and information that is useful to manufacturers. Whether you are talking about temperature sensors, distance sensors, pressure sensors, or cameras, all of these industrial elements require real-time connectivity to meet the promise of the IIoT.

- The interconnection between the IT and OT provides manufacturers with better efficiency and reliability in their operations. This access is not locale limited, data is available all over the world to anyone with access.

For example, internally at a manufacturer’s facility, it could be helpful for a production planner in Europe to access production data from different factories in real-time to optimize their workflow. Or an external partner with access, such as the maintenance or service partner for robots, could access all relevant data on the robot to enable smooth operation and service.

“Broad acceptance of this technology is important for optimal integration. The RJ45 connector is the most common used connection for data communication today (see below), and is considered the standard communication interface for industrial applications. Yet even greater capabilities can be unlocked when manufacturing customers expand their system to include new technologies like TE’s Mini I/O or SPE connectors to transform and optimize their production environment,” Rüter said.

Challenges for automation engineers

One major challenge for automation engineers managing Industrial Ethernet networks is the “possibility of rethinking processes”. For example, does it make sense to split certain steps in the production process? Which information points in the whole process could be used as indicators for better quality, fewer scraps, and/or speed recovery?

“With IIoT systems, we have access to those data points (and more) so we can share it with virtually all involved areas to identify opportunities to gain efficiency. Consider the digital twin for example. The digital twin of your machine includes information like maintenance data, runtime, error quotes, and energy consumption. But the digital twin is not only a solution for a product. Manufacturers can review the digital twin data for information about sustainability and to identify places to conserve resources. Sustainability and resource conservation are not only mega trends and significant challenges for our daily business, but they are also an opportunity to drive greater production efficiency,” Rüter said.

Another challenge is the integration of many periphery devices. Next to the data connection, power is also needed. Fortunately, hybrid SPE technologies not only provide high-speed Ethernet to the sensor, they deliver power directly as well. This not only enables a more forward-thinking, future-ready approach, it also reduces the amount of cabling required, saving valuable company resources.

“In response to increasing operations digitization and the move towards adoption of Industry 4.0 principles in various industry verticals, Industrial Ethernet technology has made great advances in recent years. Industrial Ethernet solutions are evolving to support remote access, obviating the need for more complex and potentially unsecure methods allowing machine vendors to connect to machines to monitor, troubleshoot, or configure them,” Vivek Bhargava, Product Marketing – IoT Networks, Cisco Systems.

Greater levels of connectivity

Industrial Ethernet solutions are evolving to address a wide range of performance criteria.

“In response to increasing operations digitization and the move towards adoption of Industry 4.0 principles in various industry verticals, Industrial Ethernet technology has made great advances in recent years,” Vivek Bhargava, Product Marketing for IoT Networks at Cisco, told IEB.

Bhargava summarized how Industrial Ethernet technology is evolving to provide greater levels of connectivity by concentrating on key performance requirements.

Harsher environments: Ruggedized Industrial Ethernet equipment has long provided connectivity in non-temperature-controlled environments and resistance against dust, shock and vibration, humidity, and water. For extra protection against corrosion from moisture, fine dust, salt, and chemicals, some Industrial Ethernet equipment also comes with conformal coatings on its PCBs.

Higher speeds: To support the ever-increasing needs for higher throughput, gigabit Ethernet port speeds are now quickly becoming the norm. Industrial Ethernet products also feature multi-gigabit (mGig) ports for connecting even higher bandwidth equipment such as Wi-Fi 6/6E access points, and 10 gigabit ports for uplink connections to distribution and core switching layers.

Industrial protocols, resiliency, and compliance: Compliance with industrial protocols ensures that industrial ethernet equipment can communicate with devices on the network using a common language. This, in turn, ensures that devices can exchange data and control signals reliably and efficiently, without errors or delays. It also helps to simplify the integration of new devices into existing networks. Compliance with protocols such as Ethernet/IP, PROFINET, MODBUS, GOOSE etc., are basic requirements.

Other protocols include those for timing (Precision Timing Protocol (PTP)), for resiliency (High-Availability Seamless Redundancy (HSR), Parallel Redundancy Protocol (PRP), Media Redundancy Protocol (MRP), and Device Level Rings (DLR)), as well as those for specific use cases such as IEC61850 (Electric Substations Communications).

Advanced security: Industrial Ethernet is evolving to meet more complex standards such as IEC62443 (Security for industrial automation and control systems). This standard defines the requirements for security for industrial automation and control systems, and lays out a framework for hardware integrity, asset visibility, segmentation of operations into zones and conduits, and control.

Being directly connected to industrial assets, Industrial Ethernet equipment can offer deep visibility into the identity and interactions of those assets, without the need to span the traffic to a separate server, and thus obviating the need for extra network traffic and costs of the server. This visibility can be leveraged to formulate access and segmentation policies and enhance security. Industrial Ethernet can also enforce these policies.

“Industrial Ethernet solutions are evolving to support remote access, obviating the need for more complex and potentially unsecure methods allowing machine vendors to connect to machines to monitor, troubleshoot, or configure them. This is particularly useful for organizations with multiple sites or distributed operations, reducing costs and time,” Bhargava stated.

Fostering collaboration with IT: Industrial Ethernet is evolving to enable more integration of IT solutions and practices helping operations bring the same levels of networking automation, performance assurance, and centralized policy, proven in the largest of enterprise networks. Adopting IT practices also helps in better collaboration between IT and OT by sharing knowledge and expertise, creating a shared vision, using common tools and platforms, establishing a governance structure, and focusing on common concerns such as cybersecurity.

Technology trends driving innovation

Bhargava said that “to keep up with the demand and usability that industries expect from these devices, Industrial Ethernet hardware and software is advancing at a rapid rate.”

The key technical trends can be summarized as follows:

Higher performance: Organizations are bringing an ever-increasing number of industrial assets online. Some endpoints such as high-resolution cameras, Wi-Fi 6/6E access points, and those needed for real-time communication required on the plant floor are driving the need for higher switching and routing capacities requiring Industrial Ethernet to adopt technologies and architectures from their enterprise counterparts.

Superior Power-over-Ethernet: With higher-wattage 4-pair PoE (IEEE 802.3bt) coupled with higher bandwidth multi-gigabit ports and large total PoE capacities, Industrial Ethernet can supply the required power to industrial devices requiring a larger amount of power than could be supplied with earlier PoE technologies. Devices that consume more power and simultaneously need more bandwidth such as high-definition PTZ cameras, digital signage, and Wi-Fi 6/6E access points can benefit from the mGig ports that also supply 4-pair PoE up to 90W.

Smaller form factors: Increasing number of devices and controllers constrain cabinet spaces and add engineering efforts in custom-built machinery. These environments often have limited space for networking equipment, especially in applications such as machine control or automation. Smaller equipment can help ease these constraints. However small form factor equipment must not compromise on features and speeds.

Modularity: Being able to add modules to an existing base unit helps extend the organization’s investment, allowing them to match their network investment in sync with their needs. Industrial Ethernet switches and routers equipped with field pluggable modules that add ports or allow you to switch between connectivity methods such as public or private 4G or 5G, or FirstNet, provide the needed flexibility.

Edge-computing: Edge-computing enables data processing close to where it is generated, not only reducing latency and response times but also decreasing the amount of data, and the network load, that needs to be transmitted to a central server. Computing performed in Industrial Ethernet devices themselves can even eliminate the server. Edge-computing is extremely beneficial for running applications such as deep packet inspection (DPI) for visibility on assets and their interactions, secure remote access to allow remote monitoring of assets, and for extracting real-time process data for analysis.

The result is that new Industrial Ethernet solutions are providing key technical benefits.

Interoperability: By using standard communications interfaces, Industrial Ethernet solutions replace proprietary communications technology, providing interoperability, enabling seamless communication and integration of devices and subsystems from different vendors and technologies. This promotes flexibility and innovation, as organizations can select the best products for their specific needs.

Virtualization: Industrial control systems vendors are starting to introduce software-based PLCs (Programmable Logic Controllers) that industrial organizations can install as virtual machines on the plant floor to simplify deployment, maintenance, and updates to their automation systems and dramatically reduce operational expenses. Industrial Ethernet provides the highly available, secure, and high-performance deterministic networks that such virtualization needs.

Machine to cloud connectivity: Industrial Ethernet, funneling through the enterprise network, connect operations to the cloud, enabling communications with cloud-based applications and services. This allows for real-time data collection, AI/ML aided analysis, and processing, as well as remote monitoring, control, and maintenance of industrial systems.

Applications and challenges

When looking specific applications and the types of engineering challenges that these new innovations are designed to address for customers, Bhargava outlined how greater levels of connectivity has specific impacts depending on company goals and objectives.

Process optimization: Industrial engineers are tasked with optimizing manufacturing and business processes to improve efficiency, reduce waste, and increase productivity. Visibility and real-time data that Industrial Ethernet can help obtain, can provide insights into potential inefficiencies and better control.

Product quality control: Industrial engineers are responsible for ensuring that products and services meet customer requirements and standards. This requires developing quality control systems, implementing statistical process control, and conducting root cause analysis to identify and resolve quality issues.

Supply chain management: Industrial engineers are responsible for designing and managing supply chains to ensure timely and cost-effective delivery of goods and services. This requires coordination of multiple stakeholders, including suppliers, manufacturers, distributors, and customers, and dealing with challenges such as variability in demand, disruptions in supply, and changing market conditions.

Sustainability: Industrial engineers are increasingly focused on designing sustainable systems and processes that minimize environmental impact and maximize resource efficiency. This requires incorporating green design principles, reducing waste and emissions, and implementing renewable energy and recycling programs.

Health & safety: Industrial engineers must also ensure that the industrial equipment, processes, practices, and procedures protect the health, safety, and wellbeing of workers. Industrial Ethernet can help them with tools such as remote monitoring, obtaining real-time data, and performing predictive maintenance.

Secure remote operations: Operations are challenged to provide secure access to remote workers, especially to distributed, hard to reach locations. Industrial Ethernet can enable not only connectivity over fiber or cellular but also run remote access application for a standard, consistent method that obviates the need for many and potentially unsecure techniques.

“Industrial Ethernet technology is rapidly evolving to meet the demands of Industry 4.0 and the Industrial Internet of Things (IIoT). This evolution is driven by the need for robust, reliable, redundant, and secure communication protocols that can handle large data volumes with minimal latency and downtime,” Igor Bozovic, Product Marketing Engineer, Moxa Europe.

Greater levels of connectivity

Industrial Ethernet solutions are evolving to address a wide range of performance criteria.

Industrial Ethernet technology is evolving to provide greater levels of connectivity. According to Igor Bozovic, Product Marketing Engineer at Moxa Europe, “Industrial Ethernet technology is rapidly evolving to meet the demands of Industry 4.0 and the Industrial Internet of Things (IIoT). This evolution is driven by the need for robust, reliable, redundant, and secure communication protocols that can handle large data volumes with minimal latency and downtime.”

“Advanced standards like TSN (Time-Sensitive Networking) provide deterministic communication and synchronization, while OPC UA (Open Platform Communications Unified Architecture) enables seamless data exchange. The adoption of cloud and edge computing enhances data processing and analysis capabilities. Cloud computing centralizes storage and analysis, while edge computing enables real-time processing at the network edge. These advancements enable more connected, efficient, and intelligent industrial environments, empowering organizations to achieve higher productivity, profitability, and sustainability,” Bozovic said.

Technology trends

Bozovic said there are key trends shaping the development of Industrial Ethernet products including Moxa’s switches, gateways, routers, and software solutions like MxView:

Higher Bandwidth and Speeds: Industrial applications generate increasing data volumes, driving the need for higher-speed Ethernet standards like 10GbE and 40GbE.

Enhanced Cybersecurity: Robust cybersecurity features are crucial for protecting industrial networks against cyber threats. Advanced protocols such as network segmentation, intrusion detection, and access control are being incorporated into Industrial Ethernet products.

Improved Network Management: With complex industrial networks, effective management solutions are essential. Features like remote management, automated configuration, and real-time monitoring simplify network management and enhance operational efficiency. MxView MXview One software is an ideal solution for network device management.

Edge Computing: Real-time data processing and analysis at the source are facilitated by edge computing, reducing latency, and improving performance. Industrial Ethernet products now integrate edge computing capabilities for applications like predictive maintenance and quality control.

Interoperability: Open standards and protocols like OPC UA and MQTT ensure seamless communication between devices and systems in complex industrial networks.

These trends drive the evolution of Industrial Ethernet products, enabling greater connectivity, cybersecurity, network management, edge computing, and interoperability in industrial environments.

Key technical benefits

“New Industrial Ethernet solutions bring key technical benefits that are transforming the industrial landscape. They enable organizations to improve operational efficiency, reduce downtime, and enhance safety and security,” Bozovic said.

“These benefits include increased connectivity and data exchange, improved reliability, enhanced security features, greater flexibility for adapting to operational changes, real-time data access for faster decision-making, and reduced costs through efficient operations and minimized maintenance expenses. Overall, these advancements drive the transformation of industrial environments, empowering organizations to achieve higher productivity, profitability, and sustainability,” he said.

These new Industrial Ethernet innovations address specific applications and engineering challenges in various industries. Common applications include:

Smart Manufacturing: Industrial Ethernet enables real-time data collection and analysis for improved efficiency, quality control, and predictive maintenance.

Industrial Factory Automation: Real-time communication and control through Industrial Ethernet enhance operational efficiency and reduce downtime.

Power and Energy: Industrial Ethernet enables real-time monitoring and control of power systems, improving efficiency and reducing downtime.

Transportation (ITS): Industrial Ethernet facilitates real-time communication and control in transportation, enhancing safety and efficiency.

Building Automation: Industrial Ethernet enables real-time communication and control of building systems, improving energy efficiency, and reducing costs.

Engineering challenges

Bozovic added that engineering challenges that automation engineers are facing include interoperability, reliability, security, scalability, and integration. Industrial Ethernet ensures seamless communication with different devices, reliability to minimize downtime, robust security against cyber threats, scalability to handle large data volumes, and smooth integration with existing systems.

“These innovations drive operational efficiency, reduce downtime, and enhance safety and security in industrial environments,” Bozovic said. “They cater to specific applications and overcome engineering challenges, empowering organizations across industries to achieve greater efficiency and productivity.”