TechnologyJuly 10, 2018

Advanced Physical Layer powers Ethernet to the field

Ethernet to the Field technology promises solutions for process automation and instrumentation in remote and hazardous locations. Taking process industries into the future requires a new network standard to transfer process data with the speed and flexibility of standard Ethernet and IP technologies.

DEVELOPMENTS ARE UNDERWAY to realize an Advanced Physical Layer (APL) for Ethernet that can be used in process automation and instrumentation to connect field devices in remote and hazardous locations.

Ethernet to the Field is a vision driven by new technological developments, such as the Industrial Internet of Things and the German Industrie 4.0 initiative. Both have introduced new paradigms to enable applications based on digital real-time representations of virtually any object. Existing field devices typically rely on limited fieldbus network infrastructures that hinder the implementation of highly data intensive applications.

Taking process industries into the future requires new network standards able to transfer data from instruments to communication systems with the speed and flexibility of standard Ethernet and IP technologies.

APL at a Glance

Here is an overview of the functions and features of Ethernet to the field technology:

- Ethernet-based, for any protocol or application

- Power and data over a shielded twisted pair line

- Any method of hazardous area protection especially intrinsic safety, including simple validation

- Transparent connection to any IT network

- Re-use of existing two-wire cable

- Supports the familiar trunk-and-spur-topology

- Device access anytime and anywhere

- Fast and efficient communications for automation and other applications

Tracing the development timeline

The realization of this vision began in 2011, when suppliers at the urging of end user groups began a investigation of a protocol-neutral, advanced physical layer that could solve the problem of a long-reach Ethernet for use in hazardous locations. The results of this five-year investigation proved the feasibility of a solution for this problem and also generated interest in an industry-wide solution based on IEEE Ethernet standards.

The realization of this vision began in 2011, when suppliers at the urging of end user groups began a investigation of a protocol-neutral, advanced physical layer that could solve the problem of a long-reach Ethernet for use in hazardous locations. The results of this five-year investigation proved the feasibility of a solution for this problem and also generated interest in an industry-wide solution based on IEEE Ethernet standards.

In late 2016, the IEEE Standards Association approved the IEEE P802.3cg project which focused on the development of enhancements to the existing IEEE 802.3 Ethernet standard (IEEE 802.3) for Ethernet via twisted-pair wiring (10BASE-T1L) that would allow long-reach applications and was designed for use within hazardous areas. The draft of the enhanced standard resulting from IEEE P802.3cg including specifications for short-reach constrained applications and for powering, is expected in 2018. The resulting amendment is expected to be approved in the 2nd half of 2019.

A parallel effort known as the APL Project focuses on an extension of 10BASE-T1L for the use in hazardous areas (Zones 0 and 1 / Division 1) to develop standards for all typical protection methods, especially intrinsic safety and to promote the adoption of Ethernet for process automation and instrumentation.

The APL Project is supported by key suppliers to the process industries. The project cooperates with leading standards development organizations (SDOs): the Fieldcomm Group, ODVA and Profibus and Profinet International (PI).

Key aspects of these parallel projects include efforts to amend relevant IEC standards for the installation of Ethernet devices in hazardous areas. After completion of all IEEE and IEC standards and field device conformance tests, Ethernet to the Field should finally be ready by 2022.

Process solutions for digitized world

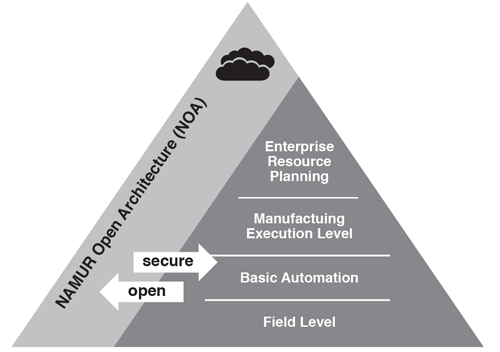

In the manufacturing industries, the Industrial Internet of Things and Industrie 4.0 are already part of everyday operations. In the near future, these technologies will also enter the field of process automation and instrumentation. In the process industries, domain-specific concepts like the Namur Open Architecture (NOA) or the Open Process Automation Standards (O-PAS) by the Open Process Automation Forum (OPAF) are presently attempting to simplify the efficient construction, commissioning, and operation of process plants. Broader use of wireless solutions, simplified field device integration and Ethernet to the field represent integral components of these concepts.

Participants in the APL project recognize the need to add the universality and communication speed of standard Ethernet to existing field device installations. Their goal is to accelerate development and adopt a new Ethernet physical layer for the use in process automation and instrumentation that can be deployed in hazardous areas, allow long-reach connectivity, and include an option for device powering over the line.

This new Ethernet physical layer, together with the automation protocols that define the structure and meaning of information being transmitted to and from field devices, are key enabling factors for the Industrial Internet of Things. It will provide the prerequisite to extend the digitized world to process automation and instrumentation.

The leading SDOs participating in the project are working to ensure that all technologies and standards will be compatible to their respective protocols (EtherNet/IP, HART-IP and PROFINET). They will also contribute to protocol-neutral conformance standards for their respective industrial Ethernet networks.

Technology and ecosystem

APL is the ruggedized, two-wire, loop-powered Ethernet physical layer that uses 10BASE-T1L plus extensions for installation within the demanding operating conditions and hazardous areas of process plants. It enables a direct connection of field devices to Ethernet-based systems in a way that process industries can benefit from a convergence of OT and IT systems. Utilizing a switched architecture eliminates any unwanted interference between devices connected to the same network.

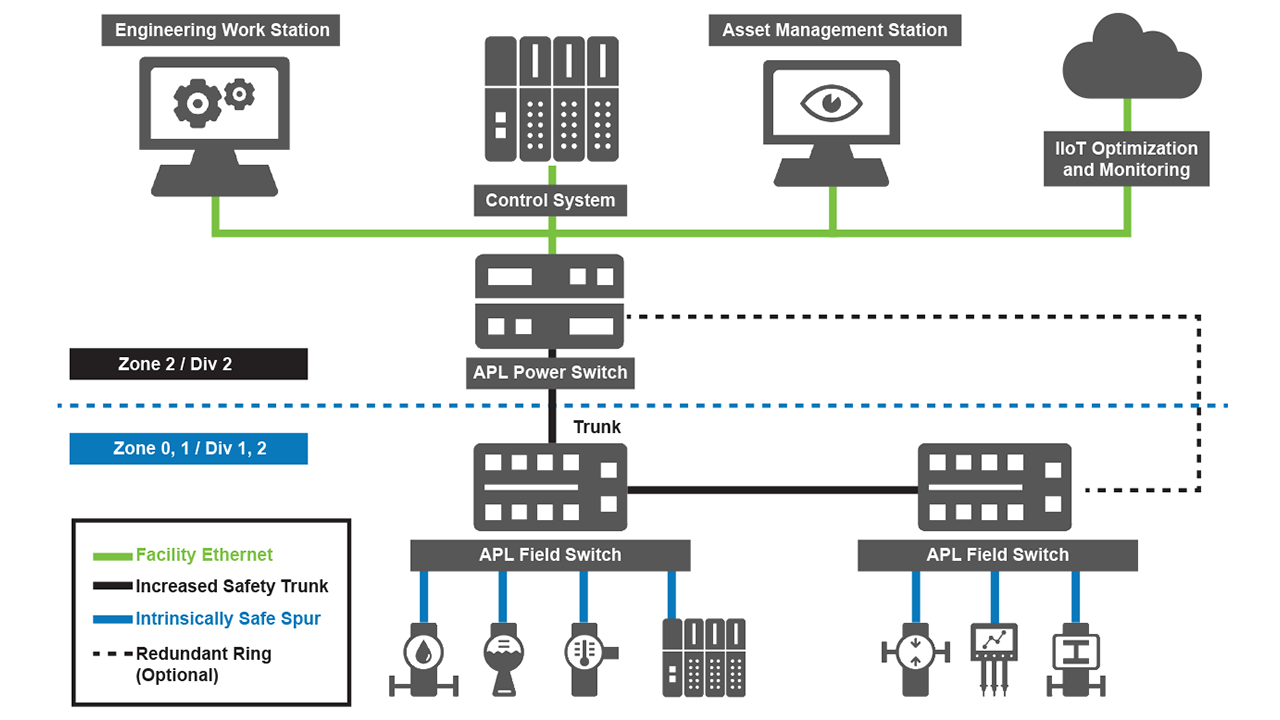

Ethernet to the field adopts technologies and options already established in the field of process automation. This includes the proven trunk-and-spur topology shown in the figure above with the ability to power up to 50 field devices with up to 500 mW each. Widely used and established cable infrastructures are specified to support the migration in brown field installations to future Ethernet connectivity.

Hazardous area protection

Methods for ignition protection follow basic rules typical for electrical installations. At trunk level, mechanical methods such as increased safety are used to transfer the maximum specified power into the hazardous area. Intrinsic safety is supported at the spur. Validation of the intrinsically safe connections is similar to FISCO, allowing a simple validation procedure for each connection without calculations.

Infrastructure

Aside from cables and connectors, an APL infrastructure consists of two basic components. APL power switches provide connectivity between all standard Ethernet networks and field devices and include power supplies that provide power to the APL field switches and field devices. They are typically located in the control room or junction box on a skid. Switches as well as and power supplies can be designed with redundancy.

APL field switches are designed for installation and operation in hazardous areas, which are typically Zone 1 and 2 or Division 2. Normally, they are loop-powered by the APL power switch and distribute both communication signals and power via spurs to the field devices.

Instrumentation/actuators/devices

Field devices with APL interface allow easy integration into higher level systems. Manufacturers can simply integrate APL into their existing product portfolio including level and flow meters, temperature and pressure transmitters, positioners or devices for liquid and gas analysis. APL technology also offers simple connection in hazardous areas for innovative devices like IP-cameras and wireless access points, enabling temporary and comprehensive monitoring for maintenance and troubleshooting.

Simple and legacy components

Simple voltage-free contacts, proximity switches, temperature sensors or simple solenoid valves and legacy instrumentation often require connection to higher level control systems. For some components ,Ethernet connectivity may not be required or economically reasonable. For such applications, Remote I/O systems provide a gateway to the future. Field devices with twisted-pair Ethernet connectivity become standard. The migration of legacy devices to the technology will be easy as the basic Ethernet infrastructure is already installed. Any solutions certified for installation and operation in hazardous areas can also be operated with the future Ethernet to the field.

The Eco System

APL constitutes a major investment by industry partners like field device vendors, automation system providers and infrastructure component suppliers. All of them share the same vision of a single, common and transparent physical layer for Ethernet in the field of process automation. With APL communication, based on established IEEE and IEC standards, certified in any region around the world, comprehensive market participation is anticipated.

APL is a foundational technology that enables broad and innovative product development. From engineering companies to plant and skid-builders, from service providers and data vendors to end users, everybody will benefit from the digitization of process plants.

With its ability to combine Ethernet communication with power over one and the same twisted-pair wiring, the new and easy-to-handle physical layer will trigger a completely new generation of devices and infrastructure components that will simplify process technology and enable completely new applications in process automation. There are virtually no limits.