TechnologyNovember 18, 2021

Assemble circular connectors with M12 Push-Lock technology

Push-Lock connection technology provides new possibilities for M12 connectors. With its convenient handling, the connection reduces sources of errors and installation times significantly. Now, this type of connection is more than equal to screw connections whether for signals, data or power.

As a part of the digital transformation, the requirements on networking industrial devices and systems are increasing. Standardized and tailored solutions are needed to be able to plan and realize reliable and future-proof cabling. Circular connectors designed for assembly with fast-connection technology and an M12 design have huge potential.

In addition to flexibility and time savings, the simplified conductor connection as well as contacts that remain stable over the long term also play a role in increasing cost effectiveness. Because by selecting the right connector, users are setting a decisive course for the future-proof cabling of their devices and systems.

In the field of M12 connectors designed for assembly, there are several connection technologies available. Here, insulation displacement and spring-cage connections have undergone massive further development in recent years, and are now the standard for M12 connectors designed for assembly. High sales figures and growth rates confirm this development. Sales of Piercecon and the popular screw connection technology are also increasing constantly. And last but not least, crimp connection technology is irreplaceable; it underpins the high proportion of connectors designed for assembly on industrial M12 cabling.

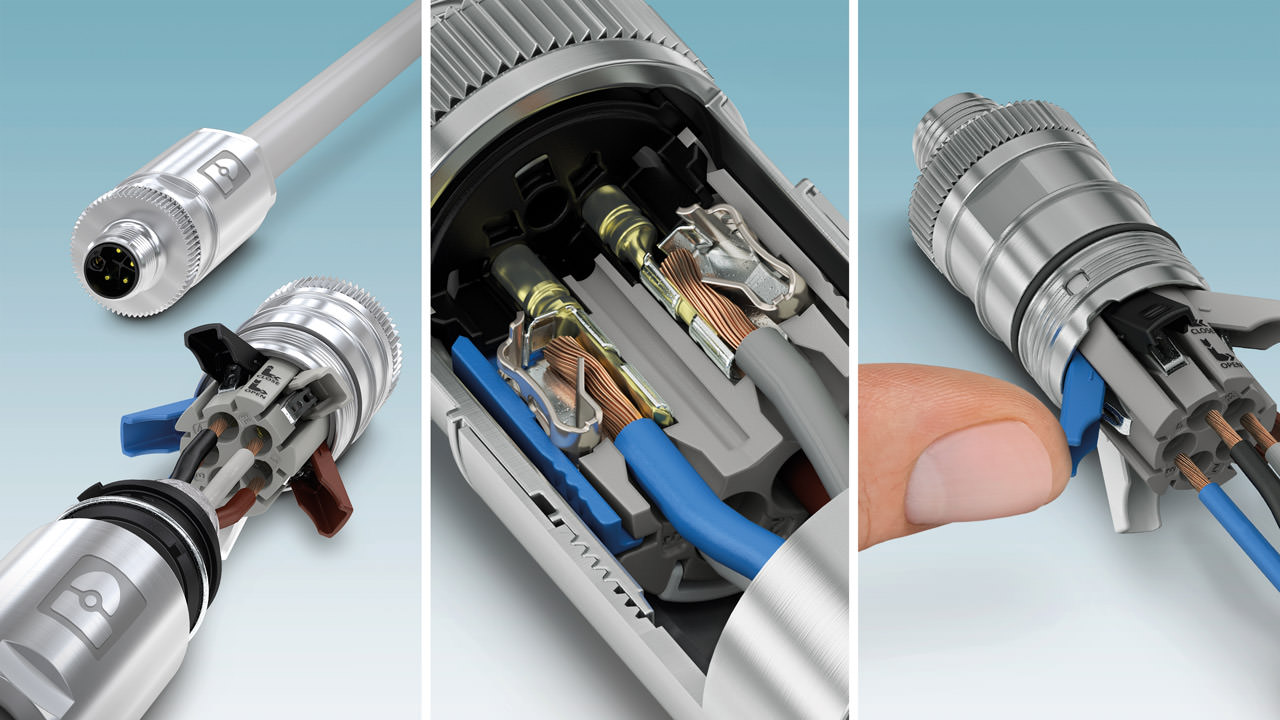

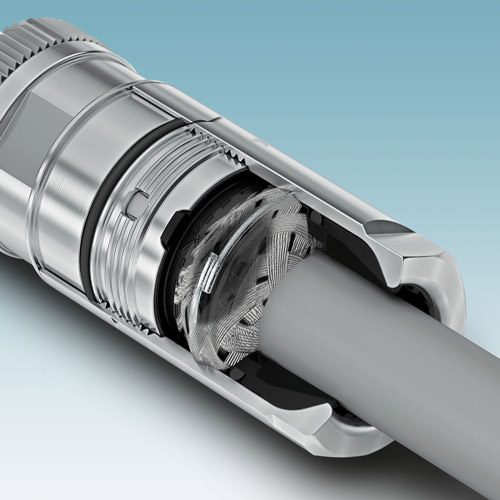

The M12 connector with Push-Lock connection combines Push-in technology and actuation lever for a simple and long-term stable conductor connection.

Connection technology depends on the application

The application is always the focus when answering the question of the right connection technology with copper-based cabling for signals, data, and power more precisely. Even if the connectors appear to be very similar on the inside at first glance, it is worth taking a closer look. Further information is available online, but samples can also be procured immediately.

Regardless of the insulation material of the conductors to be connected, the M12 connector with screw connection works; it is widely known in almost all markets around the world and is used almost universally. However, it cannot always be guaranteed that the screw is tightened with the correct torque. If it is too low, the conductor is only partially contacted, which can lead to the contact resistances increasing. If the torque is too high and there is no conductor protection, there is a danger that the conductor will be damaged under the screw, the conductor cross-section will be reduced, and the terminal point will heat up excessively. Because the correct torque is essential for a long-term reliable connection, manufacturers document it and can also be contacted for this information.

M12 connection with spring-cage

With the right torque used on the screw, the conductor connection is secure.

Connection technology using springs, the most widely known of the fast-connection technologies, appears similar at first glance, but is completely different. This technology allows the convenient connection of terminal blocks, circular connectors, and PCB connectors.

The spring-cage connection is a fast wiring option for rigid and flexible conductors, both with and without ferrules. Here, the clamping space has to be opened using a screwdriver, and then the conductor is fed in. Push-in connections go one step further – Push-in technology has gained significant importance over the past few years.

With this type of spring connection, the tool for opening is, in a manner of speaking, “included”. A lever, also known as a pusher, is pressed to open the terminal point. Once open, flexible conductors without ferrules can be fed in easily.

The lever is then released and the terminal point closes automatically. At the same time, the conductor is contacted with a defined contact force, creating a long-term safe and reliable connection. When using rigid conductors or flexible conductors with ferrules, actuating the pusher is not necessary, because the conductor can be plugged in directly. Both connection technologies ensure a robust and maintenance-free conductor connection.

Spring-cage connection with M12

While the terminal is fixed in PCB or DIN rail mounting, M12 connectors designed for assembly must be held by hand when connecting. To resolve the challenge of the “third hand”, Push-in connection technology for M12 connectors has been continually developed over the past few years. The “Push-Lock” principle has come about as a result. As with the Push-in connection, the Push-Lock connection also uses a leg spring for contacting the conductor. The function of plugging the conductor in directly, like in Push-in connections, has also been carried over.

Now, the Push-Lock connection has an even more decisive advantage when assembling M12 connectors. A lever is positioned on the clamping chamber that can be operated by hand, allowing the clamping chamber to be opened and closed. The lever features another advantage: The clamping chamber remains open and the user has both hands free to feed the conductor in.

Every installer will appreciate this feature, not just when connecting thin signal lines and data cables, but also when connecting power cables with conductor cross-sections of 1.5 mm² or 2.5 mm². The Push-Lock connection makes the work considerably easier, because it also turns the spring-cage connection into a true fast-connection technology for the M12 field.

PE connection already integrated

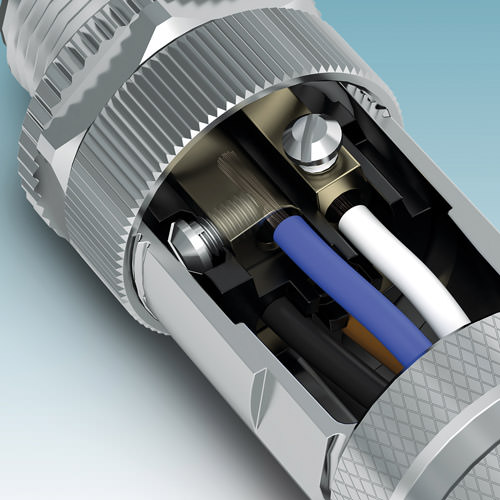

M12 connectors in shielded applications must contact the conductor shield across a large area and with long-term stability.

To design the connection to be even more intuitive, a colored marking is included in addition to the numerical marking. The levers are available in the standard colors for signal, data, and power cables to suit the application. This means it is much easier for the installer to assign the conductors, and the number of errors is significantly reduced. Moreover, commissioning the system is faster and the availability increased.

The PE connection and shielding deserve further attention. A PE connection is required for power distribution with high voltages, for example. It has to dissipate power in the event of an error and protect the user against life-threatening voltages. This function is already integrated into the Push-Lock connection. The terminal point of the PE conductor is connected internally to the metallic housing so that in the event of an error, the power is safely dissipated via the PE connection. Moreover, the lever for the PE terminal point is marked in green-yellow, which further simplifies assignment for the user.

The shield connection has long been an issue for data transmission, and field cabling must also meet the growing requirements on communication within devices and systems. Because the length of the cables installed also has an effect on data transmission, the shortest possible cable lengths are used.

To this end, assembled data cables are ordered to size or the data cable is cut to length during installation and fitted with connectors designed for assembly. Here, the M12 connectors with Push-Lock connection offer a spring-based solution that can contact a wide range of cable shielding diameters. With 360° contacting, the contact covers a large area and satisfies the demands for a low contact resistance.

Summary

With its innovative functions, the Push-Lock connection provides new possibilities for M12 connectors designed for assembly during the installation and commissioning of devices and systems. With its convenient handling, the Push-Lock connection reduces sources of errors and installation times significantly. Now, in terms of handling, this type of connection is more than equal to screw connections – whether for signals, data, or power. As a result, more and more users are taking advantage of the numerous technical and economic benefits of the M12 plug connector with Push-Lock connection.

Dipl.-Ing. (FH) Jörg Hohmeier, Product Marketing Industrial Field Connectivity, Phoenix Contact