TechnologyMay 18, 2025

CryoPhit USA delivers advanced automated cryotherapy solution

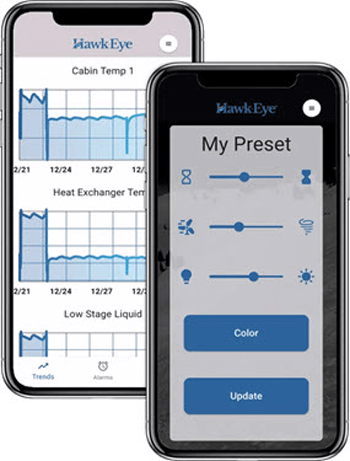

Advanced technology is empowering cryotherapy by offering seamless monitoring, diagnostics, and predictive insights. The solution had to do more than control and schedule events; it had to provide real-time data, predictive diagnostics, remote access and also integrate well with CryoPhit's HawkEye® app.

The cryotherapy industry has seen rapid growth, becoming a staple in health and wellness spas, fitness centers, and medical practices. Cryotherapy uses extremely cold temperatures to reduce pain, decrease inflammation, and accelerate recovery, making it a popular choice for healing and overall well-being.

Cryotherapy has attracted a wide range of users, from athletes seeking faster recovery to individuals managing injuries, chronic pain, or pursuing general wellness.

As demand for cryotherapy expands, the challenge of designing reliable, easy-to-maintain systems has become increasingly important.

Cryo challenges

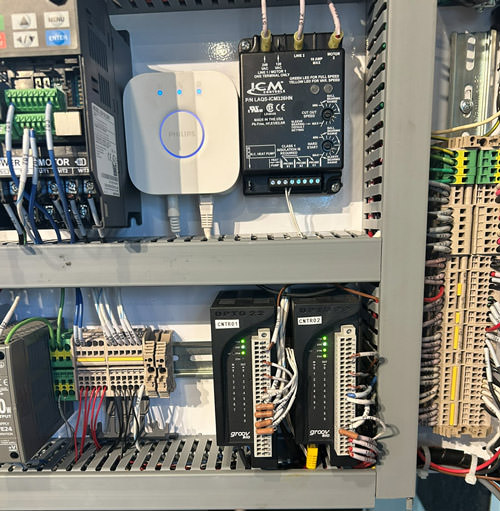

A look inside a CryoPhit USA chamber’s refrigeration and control system.

Traditional cryotherapy chambers have long relied on liquid nitrogen for cooling—a method that, while effective, comes with significant drawbacks. Liquid nitrogen (LN2) systems are expensive to operate, challenging to manage, and pose safety risks because they require ultra-cold substances and proper ventilation.

To avoid these problems, CryoPhit USA™ of Spring Valley, CA specializes in cryotherapy chambers that use electric cooling systems, offering a safer, more reliable, and easier-to-maintain alternative. But these systems come with their own complications.

“Our biggest challenge was solving the complexity of cryotherapy systems—these are specialized refrigeration systems that very few technicians know how to maintain or repair,” says CryoPhit USA co-founder John Grettenberger.

“We needed a solution that could do more than just control and schedule events: it had to provide real-time data, predictive diagnostics, and remote access,” continues Grettenberger. All this functionality also needed to play well with their app, HawkEye®.

Cryophit USA

CryoPhit USA combines a modern vision with over 35 years of industrial refrigeration expertise. Founded by brothers John and William Grettenberger, the company designs, builds, and sells cryotherapy systems to health and wellness facilities, offering both direct sales and ongoing service packages.

“People are taking personal responsibility for their health and not relying on a traditional medical model,” says John Grettenberger. “We want to be part of that.”

Evaluating options

The groov RIO is at the heart of every CryoPhit USA control system.

“Traditional systems like standard PLCs are overly complex and expensive,” Grettenberger explains. “You’re dealing with multiple layers, costly hardware, VPN setups, and extra software that make scalability a challenge. They charge so much for hardware and software, and I just don’t get it.”

With affordability, product support, and ease of use at the forefront of their decision-making process, CryoPhit USA needed a solution that avoided unnecessary complexity while delivering reliable performance.

In his 35+ years in industrial refrigeration, Grettenberger has tried products from various manufacturers.

“I was introduced to Opto 22 first with SSRs [Solid State Relays], then the SNAP PAC system, which is an industry standard for freeze dryers, but builds, and sells cryotherapy systems to health and wellness facilities, offering both direct sales and ongoing service packages.

I hadn’t seen groov RIO,” says Grettenberger. “It looked perfect.”

Opto 22’s groov RIO edge device

CryoPhit USA’s custom app displays live data and allows setpoint adjustments.

“People are taking personal responsibility for their health and not relying on a traditional medical model,” says John Grettenberger. “We want to be part of that.”

The groov RIO, Opto 22’s compact industrial edge device, features 10 software-configurable I/O channels, allowing flexible control and monitoring without the need for additional modules.

Reviewing the system’s I/O requirements, Grettenberger determined that it would take two groov RIOs to provide all the inputs and outputs required to control their chambers:

- 8 thermocouples to monitor various refrigeration and environmental temperatures

- 5 pressure transducers to monitor health of refrigeration equipment

- 2 relay outputs to activate freeze and defrost functions

- 1 analog output to vary the speed of a fan that circulates cold air to maintain the -80 °C cryotherapy environment.

And after a feasibility consultation with their software developer, the team decided to move forward with the dual groov RIO design. At a price of under $1,000 per device, CryoPhit USA was able to develop and launch their entire control system on these rugged, compact, industrial edge devices.

Technology focus

Operator UI on a CryoPhit USA cryochamber.

“Our system is far simpler [than traditional PLC systems] and uses free tools like Node-RED, which integrates beautifully without requiring additional paid software licenses,” Grettenberger adds.

CryoPhit USA has made extensive use of Node-RED—a flowchart-based tool for IIoT processes and data integration, included with groov RIO—for handling various parts of their operation:

- Equipment monitoring—groov I/O input nodes track temperatures and pressures of the refrigeration system to ensure optimal performance.

- Machine control—groov I/O write nodes activate outputs that control the chamber’s temperature and operation settings in real time.

- Communication to energy monitor— Node-RED interfaces with a three-phase power monitor that tracks all electrical phases, allowing operators to monitor kilowatt usage, calculate power costs over time, and generate detailed reports.

- App integration—using an MQTT publish/subscribe topology, the groov RIOs publish data to AWS® (Amazon Web Services®) for integration with custom iOS® and Android® apps, developed by CryoPhit USA’s software developer.

• Historical data logging—a Microsoft® SQL Server® on the AWS cloud computing platform stores operational and performance data long-term.

As CryoPhit USA develops new, potentially larger and more complex systems, the scalability features of groov allow for easy expansion.

“If we need more I/O, we can just add another RIO module, giving us 10 more points. It’s efficient, adaptable, and fits our model perfectly,” says Grettenberger.

Technology impact

Two groov RIOs handle I/O for each cryotherapy chamber.

While CryoPhit USA achieved several key advancements with its electric cryotherapy systems, the most significant result has been the ability to diagnose 80% of issues remotely. This capability has addressed one of the cryotherapy industry’s biggest challenges: maintaining specialized refrigeration systems with minimal downtime.

A system once reliant on reactive troubleshooting now uses real-time monitoring and predictive diagnostics to prevent failures before they occur. CryoPhit USA’s cryotherapy chambers minimize the need for on-site service visits, saving operators time and money.

Custom linear regression models improve failure prevention, predicting potential issues up to two weeks in advance, minimizing downtime and ensuring continuous operation—essential for operators whose revenue depends on uptime.

In addition to diagnostics, CryoPhit USA has delivered other impactful results:

- Energy management—Built-in tools track power usage, calculate costs per session, and generate detailed reports, providing operators with clear data on energy expenses.

- Scalable design—The modular nature of groov RIO allows systems to grow with customer needs, enabling easy expansion without requiring costly overhauls.

- Enhanced operator experience—Features like remote-start capabilities give operators full control from anywhere, ensuring chambers are ready

- Enhanced user experience—Users can also customize lighting and music before they begin their session, creating a personalized and immersive experience.

CryoPhit USA has turned complex cryotherapy operations into a user-friendly, streamlined, data-driven process that maximizes uptime and makes daily management simpler and more efficient.

What’s next?

CryoPhit USA remains committed to delivering reliable, straightforward cryotherapy systems, with no major changes planned for its product line.

Meanwhile, the Grettenbergers are expanding into industries with similar demands. As principals of TriplePoint Services, Inc.™, they design, manufacture, and service ultra-low temperature refrigeration equipment.

One promising opportunity lies in pharmaceutical cold storage, where compliance with CFR 21 Part 11 requirements for secure and traceable data is critical. Using the same hardware and software framework as their cryotherapy systems—groov RIO, Node-RED, and AWS— they are developing new solutions under TriplePoint Services, Inc.