TechnologyMarch 30, 2022

Flexible Industrial Remote I/O with Versatile and Easy to Use Alarm Solution

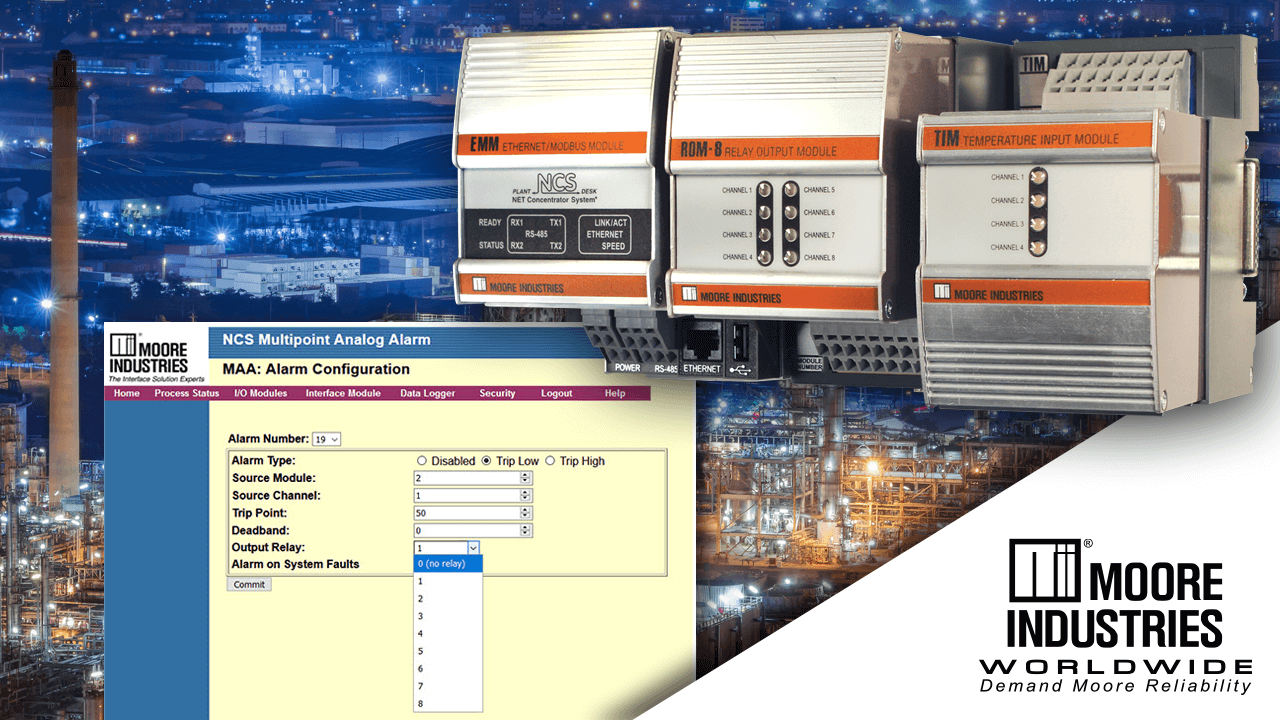

The modular and reliable NCS remote I/O system provides a real-time signal gateway between the field or factory floor and your control strategy and handles a wide range of signal inputs and outputs including current, voltage, relay, RTD, discrete, thermocouple, resistance or potentiometer.

Designed specifically for demanding industrial applications, Moore Industries’ NET Concentrator System® (NCS) features robust RFI/EMI protection, Peer-to-Host and Peer-to-Peer operation, full channel-to-channel isolation, data logging capabilities, superior 20-bit input and 18-bit output resolution, and installs in harsh ambient temperature conditions. The NCS is the ideal solution when you need to network new and existing legacy process sensors, instruments, and final control elements with monitoring and control systems.

NET Concentrator System networks are made up of one or more stand-alone I/O stations consisting of one EMM Ethernet/MODBUS Interface Module (EMM), combined with Input and/or Output Modules. Any combination of Input and Output Modules may be used within a NET Concentrator System network. The NCS comes standard with one Ethernet (MODBUS/TCP) port and dual MODBUS RTU (RS-485) ports. Each of the RS-485 ports can be configured as a MODBUS RTU Master or Slave. When configured as a MODBUS Master the NCS can read data from or write data to any remote MODBUS RTU slave. In addition, each port can be configured to support a peer-to-peer network topology where individual NCS stations can communicate amongst themselves in a publisher/subscriber fashion without the need of MODBUS host. The EMM’s Ethernet port supports communication with MODBUS/TCP hosts or enables users to read real time process data with a standard web browser via the EMM’s internal webserver.

The NCS also has a versatile Multipoint Analog Alarm (–MAA) option that allows users to quickly set up simple or dynamic alarming schemes. The-MAA option utilizes a built-in ISaGRAF program providing a flexible alarm configuration that is accessed via easy-to-use web pages through the on-board web server. With the -MAA option, a full NCS station can have as many as 60 inputs, 32 alarms and eight physical relay outputs. Each alarm can be assigned to any of the eight relay outputs on the Relay Output Module (ROM). This enables each relay output to be driven by one input/alarm or multiple inputs/alarms. A basic physical configuration of hardware to implement multipoint alarming includes the Ethernet MODBUS/Interface Module (EMM), Relay Output Module (ROM), and Temperature Input Module (TIM) or Analog Input Module (AIM).

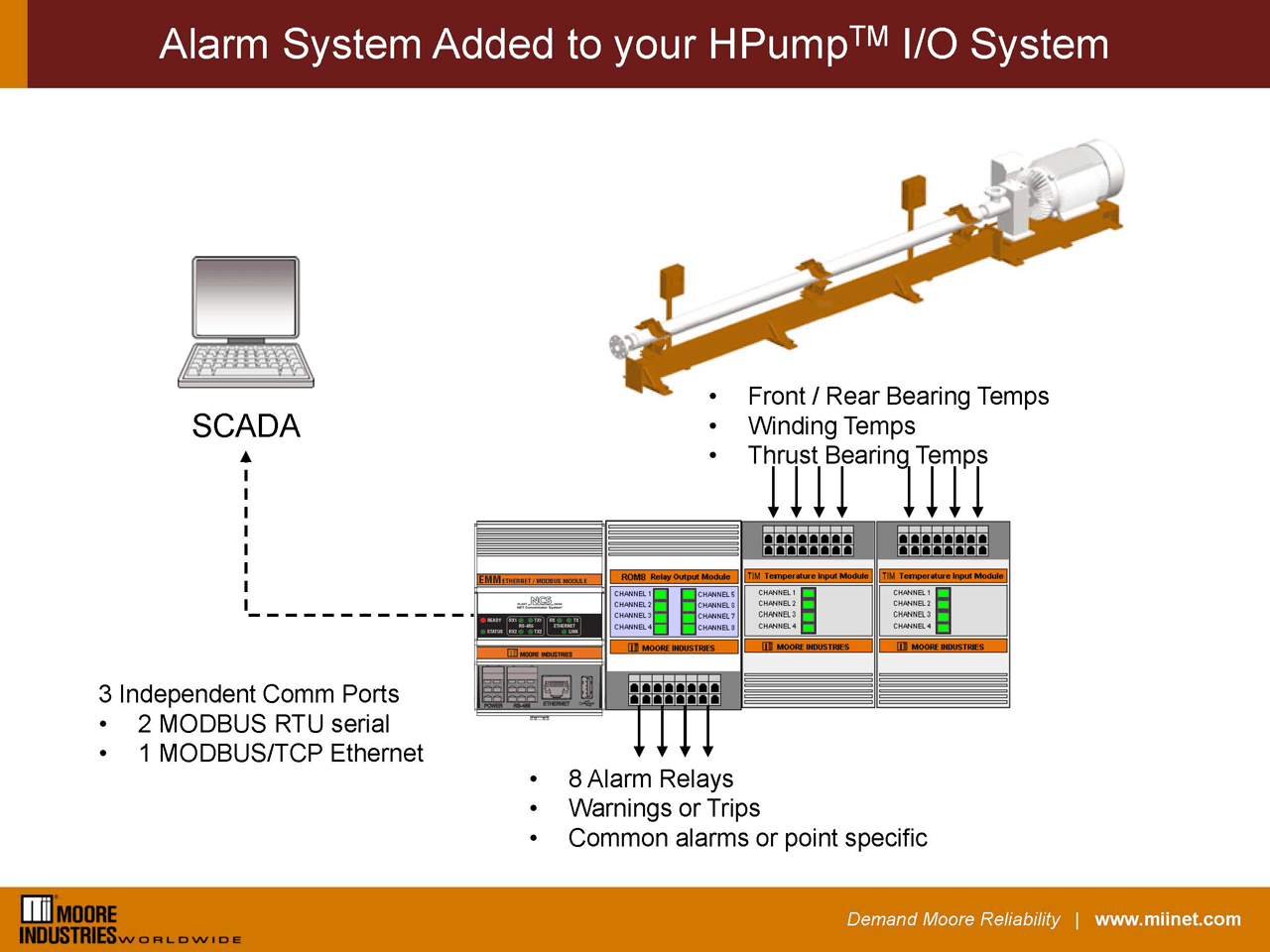

Figure 1. NCS Alarm System for HPumps

Figure 1 shows an effective application with NCS alarming capabilities for early detection of temperature excursions in HPump system motors that are used in oil and gas operations to meet a variety of pumping needs. If temperature excursions are not caught early on in these system motors, extensive damage to HPump components such as front and rear bearings, windings, and thrust bearings can occur. The NCS, with its configurable -MAA alarm capability which provides relays for warnings or trip functions, is an effective monitoring and alarm solution because it can alert the production staff of temperature excursions early on to help prevent damage and production downtime.

See the NCS with the -MAA option on the Moore Industries website by clicking on the button below.