TechnologyNovember 20, 2023

Special Report: Industrial Ethernet machine control and data connectivity

Industrial Ethernet machine control continues to leverage new software innovations, AI and cloud connectivity solutions. But Industrial Ethernet is not merely a tool for connectivity. It represents a comprehensive, secure, and intelligent networking solution is merging traditional machine control with advanced data analytics.

INDUSTRIAL ETHERNET TECHNOLOGY IS CONTINUING TO RE-INVENT ITSELF, even after 25 years in the factory — developing new levels of advanced networking solutions for industrial automation and machine control. Energized by the demands of IIoT requirements and driven by computer and software technology innovations, Industrial Ethernet continues to evolve and provide technology improvements.

For this Industrial Ethernet trends and solutions update, we reached out to industry experts to gain their perspectives on the state of machine control networking in modern factories. Here is what they told us.

Industrial Ethernet continues to move ahead

Remote access, capable routers/firewalls and fast, reliable managed switches on-site.

“Ethernet in the industrial space is evolving at a fast pace. There used to be a time where you had to be in front of a machine on site to control or gather data or really have any great visualization into the overall process. The evolution of industrial Ethernet has been able to expand us far beyond that,” Mike Willett, Network Engineer at Red Lion, told IEB recently.

Due to devices like Red Lion’s FlexEdge and Remote Access Platform, Willett said that remote access is becoming more and more accessible, easily deployable while adding a huge value to the landscape of what can be achieved on site and remotely.

“We now have much quicker response time utilizing methods to passively monitor and control systems and enable alarming to alert users when a particular process needs attention. This Industrial Ethernet advancement has made the devices inside a network perform more efficiently. This is all possible with the addition of managed switches on site with faster port speeds, more advanced traffic shaping and prioritization and much more advanced security measures to keep a network running efficiently but also very securely as well,” Willett added.

“Ethernet in the industrial space is evolving at a fast pace. There used to be a time where you had to be in front of a machine on site to control or gather data or really have any great visualization into the overall process. The evolution of industrial Ethernet has been able to expand us far beyond that,” Mike Willett, Network Engineer, Red Lion.

Expanded networking capabilities

White said that all of this is possible due to the power of remote access, capable routers/firewalls and the benefits of fast and reliable managed switches on-site. The capabilities on site have expanded tremendously with better visualization. An example is the N-Tron series NT5000 managed switches which have a modern look and feel, with a very intuitive web interface and command line.

“One aspect that is so great is that it definitely can cater to a more IT centric user with an intuitive command line structure, but it also has a very user-friendly web interface for a non IT centric user to navigate. Bringing in those enterprise level capabilities while focusing on the ease of use aspect is a huge development which allows these networking solutions to continue to shape the future of Industrial Automation. Putting that power into the hands of the industrial user and empowering them to manage the network infrastructure is a huge improvement in the overall process and efficiency of networking solutions,” Willett said.

According to Willett, new solutions can offer a variety of technological benefits while providing unique capabilities. A fully managed switch can offer faster speeds with gigabit on every port.

“We are definitely seeing the need for faster port speeds within Industrial Networking environments. As surveillance cameras and video scanners become more advanced so do the speed requirements for the network. New solutions can also offer more advanced security options. Not just security from a one device perspective but security encapsulating the entire network that spans from switches to routers to firewalls, etc. This also includes security down to the individual devices such as RADIUS authentication to authenticate a user and Port Security to further lock down ports from inbound devices and users,” he added.

The N0Tron series NT5000 switches incorporates all of these capabilities and more with a very modern design. The very intuitive and graphical web interface is designed for a user to navigate very easily. So, being able to offer a new solution that aggregates all the technological benefits but also focuses on the ease of use for the user is a huge innovation.

Types of applications

“We are seeing plant floor environments leveraging advanced networking to display manufacturing productivity. Also, the use of passive monitoring so that network related or data flow issues can be alarmed and addressed immediately rather than the potential of issues building up over time and causing real outages and downtime,” Willett said.

“Utilizing these tools upfront is essential to help reduce downtime and troubleshooting efforts that can cause delays in production. As manufacturing applications get more involved and various types of devices are introduced into the plant network, being able to utilize faster port speeds on network devices is huge. Also being able to segment traffic with the use of features like VLANs and to shape the traffic more efficiently with advanced networking can become very powerful. We are seeing the use of advanced networking everywhere from food and beverage to automotive plant networks. It is definitely emerging to every industry,” he added.

As the feature sets and technology of Industrial Ethernet become more and more advanced, Willett said that it is very important to maintain a level of user friendliness. The entire idea behind the NT5000 series of switches from Red Lion is to address exactly this.

“I always mention that this switch series can certainly cater to the IT centric user that expects more advanced tools like an intuitive command line, for example, but this user has a certain level of networking expertise to assist in this workflow that they prefer,” Willett said.

“But this series of switches can also cater to the automation engineer who needs to administer and configure the network switches but doesn’t necessarily have the networking expertise or knowledge that an IT user would have. In the web interface of this switch series there are no shortage of icons with hover over text to highlight features. Also, there is an imbedded manual in the switch under each page to further explain features and terms. There is definitely a fine line when networking becomes more and more advanced to keep the common user in mind. That means the level of user friendliness must progress as well.”

Revolutionizing machine control networking

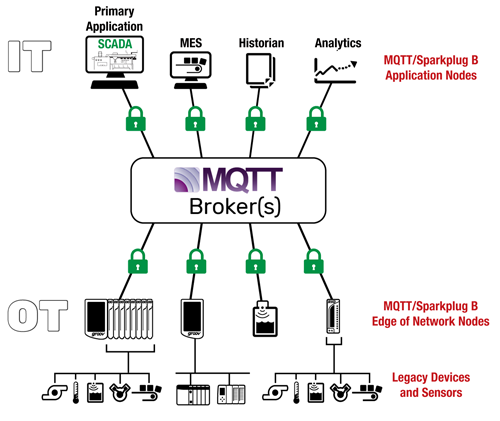

Key technologies include MQT Sparkplug B, OPC UA and RESTful APIs.

“Industrial Ethernet is revolutionizing machine control networking. Newer and more modern products like groov EPIC edge controllers integrate technologies like MQTT Sparkplug B, OPC UA, and RESTful APIs,” Daniel White, Director of Technical Marketing at Opto 22 told IEB recently. “This facilitates rapid and efficient communication between machines. The enhanced communication allows for real-time data sharing and seamless integration with cloud platforms. The cloud offers expansive data storage and provides sophisticated tools for in-depth data analysis. This analysis can reveal valuable insights, identify potential issues, and guide informed decision-making.”

White said that security remains paramount in this evolution. Modern Industrial Ethernet solutions prioritize robust security measures, employing VPNs, advanced firewall management and SSL certificates to ensure data protection. Furthermore, the incorporation of AI and machine learning into these networks is transformative. These technologies enable the network to autonomously learn from the data, refine operations, and optimize machine control processes.

“In essence, Industrial Ethernet is not merely a tool for connectivity. It represents a comprehensive, secure, and intelligent networking solution that merges traditional machine control with advanced data analytics. This integration is paving the way for a more interconnected and intelligent industrial landscape,” White said.

“Industrial Ethernet is revolutionizing machine control networking. Newer and more modern products like groov EPIC edge controllers integrate technologies like MQTT Sparkplug B, OPC UA, and RESTful APIs,” Daniel White, Director of Technical Marketing, Opto 22.

Shaping the future

Networking solutions are transforming the landscape of industrial automation. Machines are no longer isolated entities; they’re becoming part of a larger, interconnected system. By leveraging technologies like MQTT Sparkplug B and RESTful APIs, machines can communicate with each other and the cloud in real time. This communication isn’t just about data transfer; it’s about understanding and interpreting that data.

“The cloud plays a pivotal role, offering vast storage and powerful tools for data analysis. With the help of advanced analytics and AI, this data is transformed into actionable insights. These insights enable machines to operate more efficiently, adapt to changing conditions, and continuously improve,” White said.

Furthermore, the traditional barriers between Operational Technology (OT) and Information Technology (IT) are breaking down. This convergence leads to a more integrated and collaborative industrial environment. The result? A future where machine control is not just about connectivity but about harnessing the power of data for continuous innovation and growth.

“Today’s networking solutions are setting the stage for a smarter, more integrated, and data-driven future in industrial automation machine control,” he added.

Technology benefits

White added that new technologies in the industrial sector are more than just upgrades; they’re changing the way we operate. One of the biggest changes is how fast we can transfer data in real time. This, combined with machine learning and AI, means we’re not just collecting data but using it smartly. It’s not about having lots of data; it’s about understanding it and making better decisions.

Cloud storage and advanced analytics help turn this data into useful insights. Machines can now adapt and even predict future needs, making operations smoother and more efficient. On top of this, there’s a strong focus on cybersecurity. This ensures our data is safe and also helps bridge the gap securely between Operational Technology (OT) and Information Technology (IT).

In short, these new technologies are making our industrial operations smarter, safer, and more connected. It’s not just about machines doing tasks; it’s about them working together, learning, and constantly improving.

Advanced networking is making big waves in various industrial sectors, enhancing operations and bringing in data-driven solutions. Some examples include:

- Water/Wastewater Management: IIoT devices and analytics help improve treatment processes. They can predict when equipment needs maintenance, ensuring water treatment runs smoothly.

- Food and Beverage: Intelligent networking ensures high quality and safety. It uses real-time data to monitor and control factors like temperature and humidity during production and storage, while also collecting and storing data to adhere to regulatory requirements.

- Mining: Networking allows for remote monitoring and control of machinery. This not only boosts efficiency but also ensures the safety of equipment and workers.

- Concrete and Aggregates: Sensors and AI work together to perfect the batching process. This ensures consistent product quality while saving resources.

- Cold Supply Chain: Advanced networking, combined with IIoT and analytics, helps maintain the right conditions during storage and transport. This ensures product quality, meets regulations, and promotes energy efficiency.

In all these sectors and many more, advanced networking is changing the game. It’s helping industries move from just reacting to problems to predicting and preventing them. The result is smarter, more efficient, and sustainable operations.

Connectivity challenges

“Automation engineers grapple with several challenges, with cybersecurity being paramount. As they endeavor to merge operational technology (OT) with information technology (IT), they often confront the complexities of integrating older, less secure systems with modern frameworks. This juxtaposition can introduce potential security vulnerabilities,” White said.

Advanced features in new products like groov EPIC and RIO offer rich Ethernet networking security tools, providing secure and dependable connections and facilitating the seamless integration of OT and IT. Essential security measures such as VPNs, user authentication, and firewalls are now built-in as a standard practice, fortifying data protection. Additionally, TLS/SSL certificates play a crucial role in encrypting communications within the network.

“Another significant challenge is ensuring consistent and real-time data flow. Engineers require immediate data for decision-making, but safeguarding this data across diverse devices and platforms is vital. Industrial Ethernet champions newer communication methods like MQTT, designed explicitly for secure and efficient data transmission,” he said.

“Merging OT and IT offers numerous advantages but also presents inherent risks. Thanks to newer products running on Industrial Ethernet, engineers have a robust toolkit to navigate these challenges, guaranteeing that systems remain both potent and secure.”

EtherCAT technology

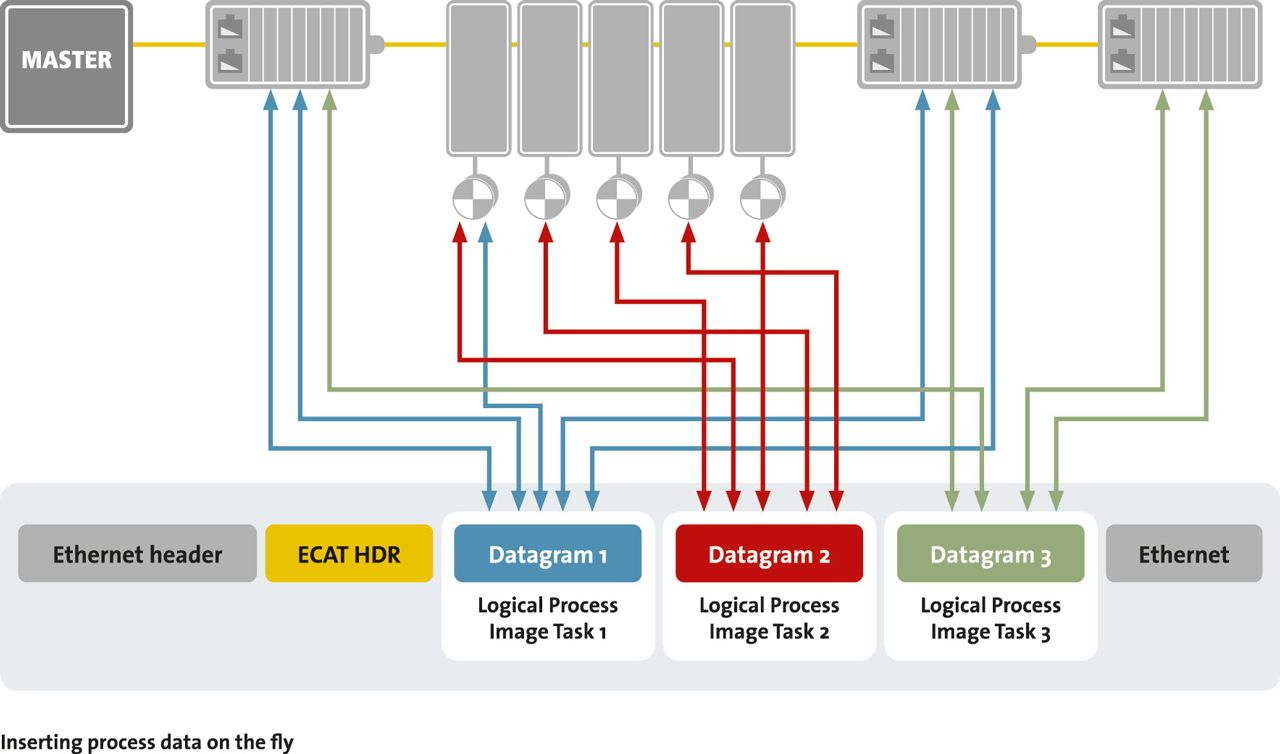

Processing of frames on the fly delivers highest network performance.

According to Martin Rostan, Executive Director of the EtherCAT Technology Group, “Industrial Ethernet technologies have become the fieldbus technologies of choice for machine controls. However, many users do not realize how big the differences are between the technologies on offer. Some even believe that it ultimately doesn’t matter which protocol is used; after all, everything is Ethernet-based and therefore has comparable properties.”

Rostan added, however, that the choice of the right technology has a decisive influence on the central characteristics of the machine or system. The bus system is the core of the control architecture because it determines whether the performance of the controller can be utilized at all. But most industrial Ethernet technologies work with cycle times of well over one millisecond and can therefore no longer keep up with the CPU performance of modern PC-based controllers which allows users to close control loops in well under one millisecond.

“But it’s not just about the cycle time, but also about the reaction time: how quickly can a control system recognize and react, for example, that a part has arrived, a cylinder has reached its end position, or another transition condition has been fulfilled. If you can react faster here, you can speed up your machine or system and achieve higher throughput – even with relatively slow mechanics,” Rostan added.

Advanced networking solutions

When asked how networking solutions are shaping the future of Industrial Automation machine control, Rostan said “it’s not only about performance. Because the bus system links the components together, it has a decisive influence on the selection of components and therefore on the cost of the control system: only a widespread bus system guarantees healthy competition between suppliers and therefore low prices.”

“And here some systems have considerable deficits, especially on the controller side, because the technology is mainly supported by one PLC supplier. It is therefore worth taking a close look when selecting the Industrial Ethernet solution and not just viewing it as a ‘by-catch’ of the controller,” he added.

“Due to its special functional principle, the processing of frames on the fly, EtherCAT fulfills the above-mentioned performance requirements particularly well; it is not for nothing that the technology is regarded as by far the fastest Industrial Ethernet technology,” Martin Rostan, Executive Director of the EtherCAT Technology Group.

EtherCAT technology benefits

“Due to its special functional principle, the processing of frames on the fly, EtherCAT fulfills the above-mentioned performance requirements particularly well; it is not for nothing that the technology is regarded as by far the fastest Industrial Ethernet technology,” Rostan said.

“It is easy to demonstrate that EtherCAT and PC-based control improve the throughput of many systems by several percent. EtherCAT is not only particularly fast, but also particularly easy to use; you don’t need switches or routers and you don’t need to be an IT expert to use EtherCAT. The addresses are distributed automatically during start-up; EtherCAT supports any network topology with virtually no restrictions and the diagnostic properties of EtherCAT are unique. Safety over EtherCAT provides integrated functional safety and EtherCAT P combines data and power supply on the same cable, eliminating the need for a separate supply cable. EtherCAT therefore has a whole bundle of unique selling points, which has led to the technology having by far the greatest variety of devices on the market.”

Machine control applications

Rostan said that, while EtherCAT was initially used primarily in applications that benefited in particular from its outstanding performance, the technology has now established itself in almost all areas of application. He added that, after all, the handling benefits, robustness, simple commissioning and low costs come into their own almost everywhere.

EtherCAT is used in all types of manufacturing machines from semiconductor production, to plastics machines and machine tools. EtherCAT is used in intralogistics, in packaging technology, in mobile machines and in power generation and distribution, and even space technology relies on this innovative and proven technology. Even the process industry is increasingly recognizing the advantages of EtherCAT, especially as high availability and the connection of intrinsically safe sensors and actuators are no problem with EtherCAT.

Engineering challenges

Rostan said the one challenge for system engineers implementing these types of systems is the increasing demand for cyber security resilience of the connectivity solutions used. Two aspects are primarily important here.

Firstly, the system architecture, which must ensure that not every I/O node and drive is exposed to direct attacks via the company network. A hierarchical architecture has proven its worth here: the controller separates the subordinate network from the company network in terms of both performance and security and acts as a kind of firewall, while at the same time providing structured process data and status information and enabling controlled and security-monitored access to the subordinate devices.

And secondly, the integrated properties of the underlying bus system must ensure that any attack on the system itself does not lead to success. EtherCAT also has advantages in this respect: as EtherCAT is not based on the Internet Protocol, the attack surface is massively reduced from the outset, and non-EtherCAT frames are recognized and filtered out by the EtherCAT chips in hardware.

“With EtherCAT, even a network node with compromised firmware cannot influence the other nodes. EtherCAT is therefore ideally prepared for the challenges of the future,” Rostan said.

“A cohesive, comprehensive networking architecture is a must for modern operations. Operations have sometimes grown over the years in a piecemeal fashion and consist of a variety of networking equipment with their own management systems, and no consistent way to secure them,” Vivek Bhargava, Product Marketing Manager, Cisco Industrial IoT.

AI and cloud operations

Industrial Ethernet solutions are helping make advances possible.

According to Vivek Bhargava, Product Marketing Manager, Cisco Industrial IoT, Industrial Ethernet is advancing the state-of-the-art in machine control networking.

“AI and cloud solutions are driving the biggest changes in industrial operations. AI enabled applications in datacenters and cloud rely on accurate and timely data from operations processes to derive insights to help improve product quality, product yield, perform maintenance, etc. Corrective actions flagged by these insights need to be brought back to operations for a “closed loop” machine control. Today’s Industrial Ethernet solutions are helping make these advances possible,” Bhargava said.

To enable these applications, industrial networking extracts, transforms, and transports operations data in real-time to the datacenter or cloud. Most of the communication between devices in production environments is local to the LAN and never leaves the network segment. With newer advancements, some traffic needs to flow between the zones and the applications. Some of this traffic could potentially require higher bandwidth, for example, high-resolution video captured by cameras used to monitor product quality. This not only increases the complexity of networking within the zone, but also all the networking components that connect to the cloud.

“Such use cases are driving requirements for an increase in network bandwidth capacity. The increasing dependency on the network also means that the network performance itself needs to be monitored and always assured,” Bhargava added. “Modern Industrial Ethernet now offers GE, mGig, and even 10GE speeds. Intelligent management of industrial Ethernet switches helps assure this performance so that production uptime is maintained. Security constructs built in the switches further protect operations.”

Industrial automation networking

Bhargava said that a cohesive, comprehensive networking architecture is a must for modern operations. Operations have sometimes grown over the years in a piecemeal fashion and consist of a variety of networking equipment with their own management systems, and no consistent way to secure them. This increases network complexity and necessary changes like expanding production lines, adding new assets, or changing the product mix become very difficult. Extracting meaningful data and introducing software-based control by connecting such operations to applications in the cloud is nearly impossible.

Networking solutions are responding to these challenges. Architectures like Cisco and Rockwell Automation developed Converged Plantwide Ethernet (CPwE) is an example of a complete networking, management, and security solution. CPwE provides a validated implementation for secure connectivity between the lowermost cells and zone to control systems over to IT managed enterprise network and the cloud.

Wireless solutions are making autonomous guided vehicles (AGV) mobile robots possible on factory floors, warehouses, and distribution centers. Secure Access Services Edge (SASE) architectures are easing secure connectivity of distributed field assets. Security advances that leverage the network rather than depend on complex set of firewalls are improving visibility, limiting malware flow by segmentation, and making remote access to industrial assets simpler.

Benefits and unique capabilities

“An integrated network architecture offers a standardized, validated, and proven blueprint ready for deployment. It allows for easy scalability as it follows well-defined guidelines and best practices. This makes it easier to add or remove network components as the organization’s needs change,” Bhargava said. “Standard network architectures ensure compatibility and interoperability between various network devices and components. This simplifies the integration of equipment into the network, allowing for seamless communication and data transfer.”

With a standard architecture, network administrators can efficiently manage and maintain the network infrastructure. Following consistent processes and procedures for configuration, troubleshooting, and monitoring, leads to improved network performance and reduced downtime – making it simpler to incorporate security best practices and protocols and implement robust security measures.

Bhargava said that cybersecurity measures must be built into a network design. CPwE, for example, relies on Cisco Cyber Vision, a visibility sensor that runs within Cisco industrial switches avoiding the need for laying out extra SPAN networks and servers. The visibility insights help inform segmentation policies to contain any malware and protect operations. Such security measures also include zero-trust network access (ZTNA) to allow workers to remotely access assets in a secure and controlled manner, with the switches acting as gateways.

Using a standard network architecture helps in reducing costs associated with network design, implementation, and maintenance. They are well-documented and widely supported by various vendors. This means that organizations have a larger pool of vendors to choose from for their network equipment, software, and services.

Advanced networking in manufacturing

“An advanced technology now being increasingly being used in manufacturing is communications redundancy,” Bhargava said. “This means every Ethernet frame from the source is replicated across different and separate network devices and delivered to the destination. The technology is called Parallel Redundancy Protocol (PRP). It works at the Ethernet layer. By replicating all the Ethernet frames, the reliability and dependability of the communication between two devices really increases.”

Control systems virtualization, a recent advancement in manufacturing environments depends on the reliability and dependability that PRP enables. Virtualizing PLCs and other hardware resources involves removing dedicated hardware systems from the factory floor to onsite datacenters. Virtualization can provide a host of benefits including better scalability and agility, increased security, improved disaster recovery, and better sustainability.

However, for this virtualization to work, the network that connects assets to controllers must be highly available to ensure uninterrupted production. While high-bandwidth, high-performance, continuous monitoring, QoS parameters such as delay, latency, jitter, etc., are important, the network must also provide deterministic delivery and guard against packet loss. Usage of PRP is a must to ensure uptime.

Implementation challenges

Bhargava said that the biggest challenges that automation engineers face in this age of Industrial IoT is the exploding number of devices and sensor that they need to deploy, the network that must be built to connect these new assets, and to ensure the performance and security of such networks. Connecting operations to software applications in datacenters and cloud also adds new requirements that automation engineers may not be equipped to handle.

Automation engineers should partner with the organization’s IT department. IT knows how to deploy, scale, and maintain large networks, whereas the engineer knows the production assets and their connectivity needs. Industrial Ethernet and associated management and security tools make achieving this collaboration much easier. For example, when Industrial Ethernet switches are managed and secured by the same set of tools that IT knows and trusts.

“Cisco Industrial Ethernet switches incorporate several security measures, as well as integrate with tools such as AAA servers (such as Cisco Identity Services Engine), SoC platforms (such as Cisco XDR) for incident detection and response. These capabilities directly address automation engineers’ challenges allowing them to focus on production processes, incorporate new innovations, and not have to worry about whether the network is up to the task,” he said.

Impact of Time-Sensitive Networking

Single converged network architecture enabled by adoption of TSN.

According to John Browett, General Manager, CC-Link Partner Association Europe, it was often necessary in the past to use separate networks to address each type of control traffic on a machine. This often meant a separate network was used for functions such as safety, I/O and motion control, etc. Moreover, if there were functions not directly related to real time control, such as TCP/IP traffic related to printers, bar code readers or video, etc., this was also handled separately.

“We are now seeing a move towards a single converged network architecture that delivers a number of key benefits by combining all of these different traffic types together onto one network,” Browett said. “This is being enabled by the adoption of Time-Sensitive Networking (TSN). This is an extension of Ethernet that enables determinism and provides the foundation for converged networks. Another key topic relates to the “explosion” of data that is related to the introduction of Industry 4.0. More devices are producing more data, which, if properly handled, can provide valuable insights for optimizing processes. This is driving the move to industrial Ethernet that offers gigabit bandwidth as a means to handle this data effectively.”

“We are now seeing a move towards a single converged network architecture that delivers a number of key benefits by combining all of these different traffic types together onto one network. This is being enabled by the adoption of Time-Sensitive Networking (TSN). This is an extension of Ethernet that enables determinism and provides the foundation for converged networks,” John Browett, General Manager, CC-Link Partner Association Europe.

Networking solutions

Browett said that a key concern for any company is to make sure their processes are operating in the most optimized way. This will allow maximum productivity, minimum waste, and so on. Combined together, these allow the highest level of competitiveness in their industry.

“To help achieve this, it’s necessary to have a clear understanding of what the process is actually doing. The advent of Industry 4.0 is seeing the introduction of systems that can produce a tremendous amount of data regarding their operation. TSN is a key tool to help increase transparency of processes, as instead of multiple disparate streams of data all having to be analyzed separately, the opportunity now exists to combine them together and deal with them as one coherent picture. This is a key contributor to increasing transparency and therefore process optimization,” Browett said.

“When gigabit bandwidth is added to the picture, this allows more data to be handled more easily, further contributing to performance and accelerating the ability complete analytical tasks faster.”

New solutions offer unique capabilities

Since it’s no longer necessary to have separate networks for I/O, motion, safety and IT related functions, the engineering effort of machines is reduced, as now multiple separate networks can be reduced to a single architecture. Hence costs are reduced, as less development time and hardware is required. This then translates into greater competitiveness as machine costs and time to market are also reduced.

When a machine is up and running, it also means increased uptime, as simpler systems are easier to maintain. Non time critical functions, such as printing a shift log, or maintaining a video stream, can share the same network with time critical, deterministic data such as I/O or motion control, without getting in each other’s way.

As we have seen, it also helps to increase the transparency of the process. This means productivity is increased, because the process can run in a better way and have increased uptime as we just mentioned. In the end, this is the key point. Customers want to know that a new technology can help address their business challenges.

Advanced networking in manufacturing

Browett said that CLPA is already seeing over 100 companies worldwide who have adopted TSN in their operations. These cover a wide range of industries such as automotive, semiconductor, food & beverage, lithium batteries, consumer packaged goods and consumer electronics.

A specific example is Keller, a leading OEM of machines that perform screen and pad printing as well as hot stamping based in Poland. They have developed an innovative new machine that leverages TSN network technology to deliver next level productivity via deterministic motion control over 65 motion axes. This has resulted in significant improvements in terms of performance, accuracy and precision.

“The machine offers end users a modular, versatile solution that delivers enhanced productivity, cost-effectiveness, flexibility and high print quality. Moreover, the setup is scalable, as it can incorporate up to 8 different colours (and their necessary axes) and is completely reconfigurable. It can be extended to include additional printing modules to deliver a highly integrated system,” Browett said.

Keller identified the convergent network architecture benefits that TSN can deliver for future development and plans to add additional machine functions like vision systems on the same network architecture.

Challenges for automation engineers

Browett said that ongoing challenges relate chiefly to engineering machines faster, reducing costs, making them more productive and reliable. TSN can assist automation engineers to address all these challenges as we have seen already. It can reduce the complexity of a system, thus making it simpler to engineer and therefore quicker to produce a design, helping to decrease time to market.

Machines that take less time to develop and are simpler consume fewer engineering resources and have lower hardware costs, thus decreasing overall costs. This means that a more competitive product can be offered.

“Once out in the field, we have already outlined how the benefits of TSN allow machines to be operated in a more efficient, optimized way, since the processes they contain can be understood better due to the increased transparency. This leads to a more productive manufacturing line. Since the systems are less complex, maintenance becomes less of an issue, meaning that when problems do occur, they can be addressed more quickly, leading to greater uptime and increased productivity,” he noted.

“Industrial Ethernet is continuously evolving to make it possible for significant increases in efficiency as well as innovative business models for OEM machine builders. With ever-present supply chain challenges, OEMs often wait on device availability, and this can reduce the time allocated for machine commissioning in order to keep the project on schedule,” Steve Fales, Director of Marketing, ODVA.

Industrial Ethernet continues to develop and evolve

Leveraging bandwidth into greater efficiencies and smoother device integration.

“Industrial Ethernet is continuously evolving to make it possible for significant increases in efficiency as well as innovative business models for OEM machine builders. With ever-present supply chain challenges, OEMs often wait on device availability, and this can reduce the time allocated for machine commissioning in order to keep the project on schedule,” Steve Fales, ODVA Director of Marketing, told the Industrial Ethernet Book recently.

“New technologies such as LLDP, which is available with EtherNet/IP and other industrial Ethernet networks, can allow machine builders to simplify and shorten device commissioning through automatic discovery of devices, enabling smoother device integration. LLDP also increases security by transmitting device information to directly connected peer devices, since a connection isn’t needed to obtain the network topology.”

Fales said that the increased speed and bandwidth of Ethernet has opened the door to a wide variety of network and device information that was previously not possible. Industrial Ethernet enables additional diagnostic information as well as remote connectivity to allow OEM machine builders to sell service contracts, without having to have personnel ready to get on a plane 24/7 or be located onsite, and even offer machines as a service that can be billed by usage. EtherNet/IP, in particular, provides access to the Big 12 network diagnostics that expose key network health and device loading information via the standard network diagnostic assembly.

The future of industrial machine control

“The future of machine control is poised to transition from running static control programs and having maintenance workers reacting to devices failing, to control programs that learn over time and are capable of predicting when devices need to be replaced,” Fales added. “One of the key steps in the process of enabling data to be transferred from a PLC to the edge and/or cloud for analysis and action is to ensure that the field devices support data models such as PA-DIM and OPC UA as well as standardized diagnostics such as NAMUR NE 107.”

Data scientists today spend a lot of time cleaning and organizing data, which isn’t a scalable approach to enable a future powered by machine learning and predictive maintenance. Instead, data will need to be labelled and contextualized in a consistent manner regardless of communication protocol or device manufacturer. This will ensure that data is ready for machine learning and predictive maintenance analysis. EtherNet/IP supports PA-DIM, OPC UA, and NE 107 to provide end users with the critical information when and where they need it to make informed business decisions with the aid of automated tools.

Solutions and technology benefits

Fales said that solutions such as standardized information models for Industrial Ethernet can make technology like augmented reality more accessible, since the data is ready to be used, which can help to increase worker efficiency by making training manuals, device replacement instructions, and diagnostic explanations for machines more easily available. Additionally, Industrial Ethernet has made safety networking possible without a separate hardwired safety system.

“This has helped safety to become more common and enabled smaller safety zones that don’t require a whole machine to shut down when a hazardous area needs to be briefly accessed by a worker,” Fales said.

CIP Safety for EtherNet/IP is an Ethernet enabled solution that allows for small light curtains to be placed in many areas of a machine to increase worker safety and efficiency. Additionally, security is another service that can be built into Industrial Ethernet to allow for device level protection for secure remote access by OEMs to enable 24/7 service for end users. CIP Security for EtherNet/IP provides device level security as a part of a defense in depth approach for automation networks.

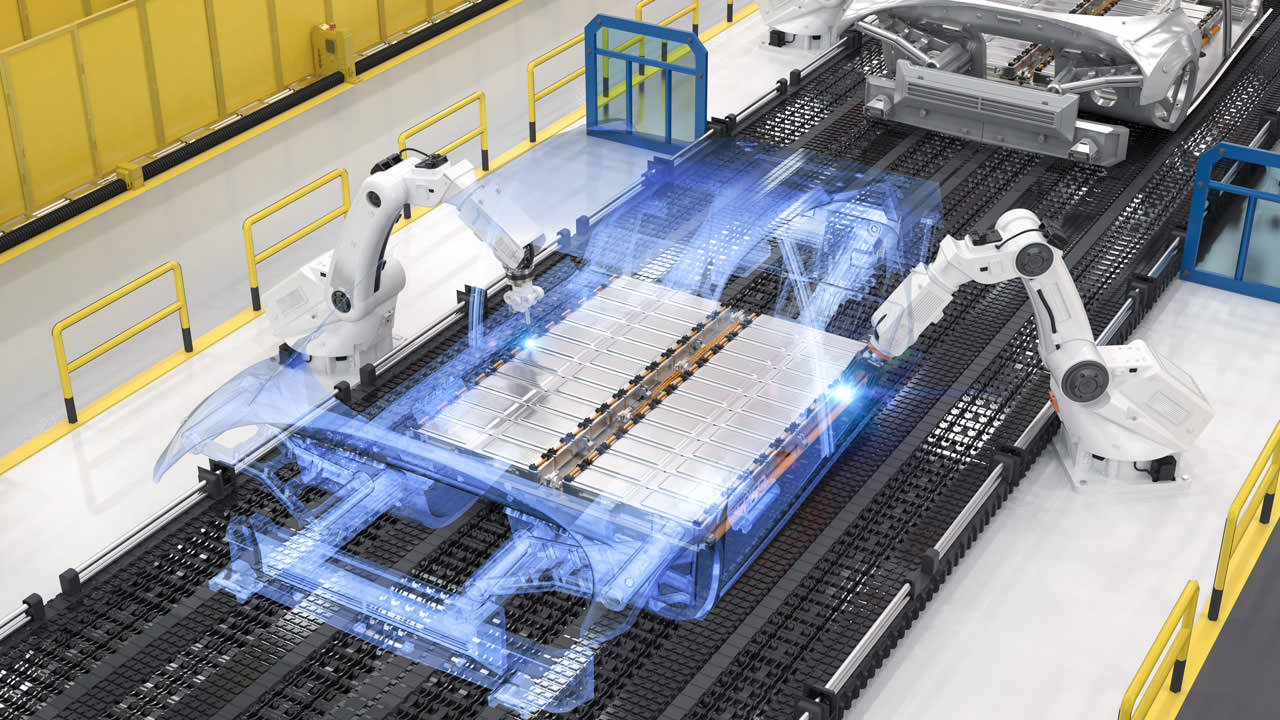

A wide variety of applications also utilize advanced Industrial Ethernet networking features such as safety networks for stamping equipment and robotic welding or preventative maintenance predictions for packaging machinery and conveying systems.

Fales said that one of the newest applications for Industrial Ethernet has been wireless solutions such as Wi-Fi and 5G. An example is an Automated Guided Vehicle (AGV) in a factory moving on a fixed route to supply components to a machine or to transport finished goods to a delivery vehicle loading area. This requires the usage of Industrial Ethernet, wireless, and safety together. EtherNet/IP can be used in this application since it is a physical layer independent protocol that can run over 5G and offers the CIP Safety extension.

The devices on the AGV would use CIP Safety to detect any failures in communication and that would then cause the system to move to a safe state. Additionally, wireless AGVs can transmit data about the number of components or finished goods that have been transported over a given period of time via Industrial Ethernet to provide a better understanding of operations and how to improve them. This data can be transported either to the edge or to the cloud for further processing or inclusion in KPI dashboards making the promise of IIoT a reality.

Application challenges

When asked about application engineering challenges, Fales said that automation engineers are tasked with continuing to increase efficiency while maintaining reliable, safe, and secure operations. Industrial Ethernet has offered scalable and proven solutions for many years to automate basic repetitive tasks in a safe manner to allow workers to focus on higher value activities.

This has been accomplished via combining the increased speed and bandwidth of Ethernet combined with specific accommodations for the industrial environment such as safety where protocols like CIP Safety are capable of detecting communication errors via diagnostics and internal calculations to ensure that the device moves to a safe state if any issues are found.

“Industrial Ethernet will also be up for the challenge of integrating wireless, security, preventative maintenance, and machine learning into machines to continue to increase Overall Equipment Effectiveness (OEE) as the era of Artificial Intelligence is set to begin,” he said. “This will be accomplished through Industrial Ethernet communication networks that are physical layer independent, utilize open security standards, and support standard information modeling, such as EtherNet/IP.”