TechnologyMarch 9, 2020

Ethernet Advanced Physical Layer for process control

Focus on an Ethernet-based single network vision includes one common communication technology for all automation levels. Ethernet technology is key to accessing data from smart instruments. In combination with PA-DIM, which is currently in development, new possibilities for future digital services can be achieved.

Industrial Ethernet is mainly used in factory automation, and only partly in process automation. However, Ethernet in the field would provide higher data transmission speed, ease-of-use and interoperability. In addition, smart instruments with Industrial Ethernet are vital for Industrie 4.0 and IIoT use cases. By these advantages the value generated by the process plant is increased.

Smart instruments which are already on the market today, are not suitable for use in all areas of process control, e.g. in explosion hazardous areas or where separate power is not available. Main issues occur with the physical layer which does not fulfill all requirements of process industries: long distance, power supply and communication via the same 2-wires and intrinsic safety.

To solve these problems, the user organizations PI (Profibus & Profinet International), FieldComm Group and ODVA cooperate with major device vendors to work on the Ethernet Advanced Physical Layer (APL). As Ethernet-APL effects the physical layer (layer 1), the integration of the specification is neutral to communication protocols. This integration in the respective IP-based protocol standards is foreseen in 2020. Afterwards, devices for the complete network infrastructure are expected.

Ethernet-APL enables access to data which is dormant at the field level today.

Based on the diversity of the mentioned organizations, the large number of industry partners who contribute to the Ethernet-APL project, the resulting IEEE and IEC standards and on a focus on customer needs, this technology will achieve major advantages for the process industry.

Single network vision

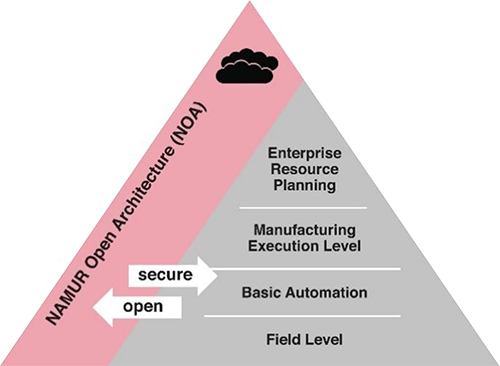

Focus on an Ethernet-based single network vision in an industrial plant includes one common communication technology for all automation levels.

The thinking starts with the evolution of communication protocols to get an understanding for the logical next step – Ethernet-based communication in process automation.

The article presents all relevant details that are necessary to achieve this vision, from organizational setup to technical insights and finally the expected timeline. As the technical specifications are not finalized yet, the technical details are not part of the article but only the reference to the respective specifications.

Based on first customer experiences gathered during a pilot test in a chemical plant, the advantages of the technology are proven. Finally, an outlook shows related topics such as impacts on safety applications or the Process Automation Device Information Model.

Process control technologies

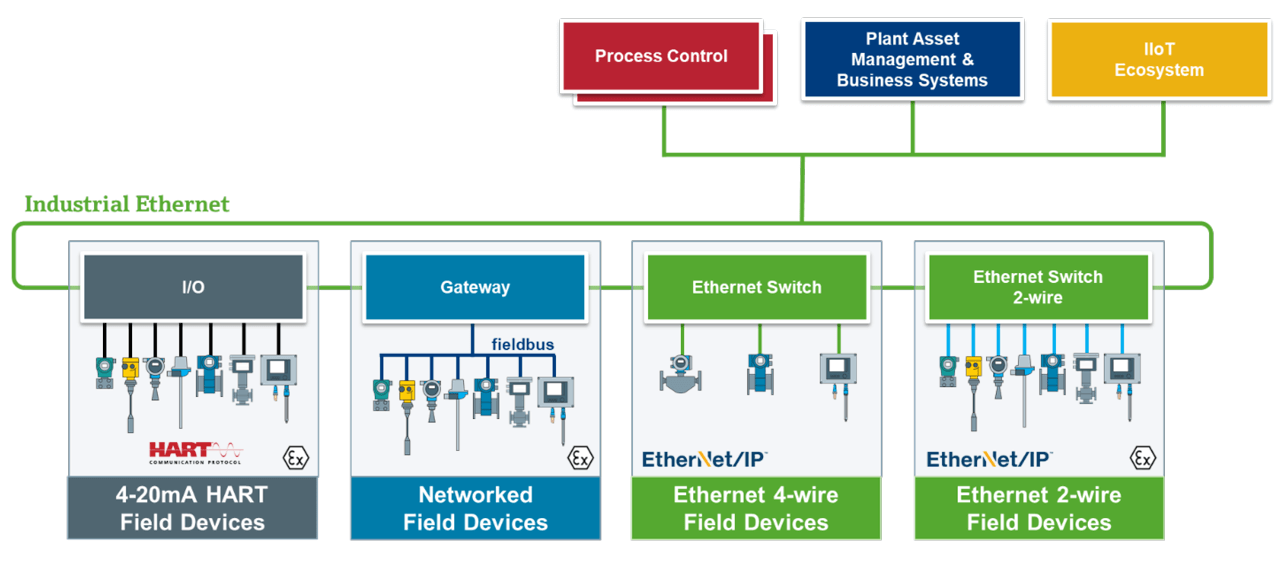

Overview of topology concepts.

By standardizing the HART protocol in the 1980s, the first step of digitalization was done. With this protocol, which can easily be introduced for plants with pre-existing 4-20 mA analog wiring and technology, it is possible to unlock data of smart instruments. The technology is still wide-spread in process automation.

In the 2000s, fieldbus protocols like PROFIBUS PA or FOUNDATION Fieldbus were introduced which provide faster data transmission rates, more standardized functions for diagnostics or device exchange. Both, 4-20 mA including HART systems and fieldbus systems satisfy the harsh requirements of process industry such as power over the cable which reduces the wiring in a plant or usage in hazardous areas.

However, fieldbus systems were not able to replace traditional HART systems which might have various reasons, e.g. do process control systems only use the process values but not the comprehensive diagnostic and parameterization possibilities.

In traditional infrastructures, the data is locked in the field and control level (OT = operational technology) which are based on these traditional communication technologies and is separated from upper management levels (IT = informational technology) which are typically Ethernet-based.

By using Ethernet technology based on current IEEE Ethernet specifications and in combination with Industrial Ethernet protocols like EtherNet/IP, more transmission speed and bandwidth was achieved. However, this physical layer has limitations such as 4-wire Ethernet cables, less cable lengths and it is not suited for installation in explosion hazardous areas.

Driven by future system concepts with data-intensive applications like the Industrial Internet of Things, Industrie 4.0 and the NAMUR Open Architecture, the requirements and communication technologies might change. All these future concepts require data from the smart instruments with no need for interpretation and transformation of the data between the automation levels.

In factory automation, the barrier of consistent communication between IT and OT was already overcome since some years, based on existing Ethernet technology.

In process automation, there are requirements which are not covered by Ethernet specifications yet. These gaps were identified and shall be solved by a new Physical Layer for Ethernet.

Barriers in process automation

In the process industry, aspects like topology (trunk/spur installation), two-wire technology (communication and power supply over the same cable), long distances and intrinsic safety, in particular, are paramount. “Long distances” refers to cable lengths of several hundred meters, with spans even up to 1,000 m having to be overcome.

Since the supplying of power to field devices over the same 2-wire cable used for data communication has proven itself in previous fieldbus installations, this feature should not be left out. The installation of Ethernet-capable field devices in explosion hazardous areas rounds out the requirements of the process industry.

For future system concepts with IIoT use cases, requirements came up as described by the single network vision. Standard Ethernet technology based on IEEE 100BASE-TX and traditional systems with 4-20mA including HART or fieldbus infrastructure do not fulfill all these requirements.

To solve all these requirements and support the Single Network Vision in process plants, the Ethernet-APL project was established.

Ethernet-APL organization

The industry organizations FieldComm Group, ODVA and PROFIBUS & PROFINET International cooperate on the Ethernet-APL project. Industry partners in this project are leading companies in process automation: ABB, Emerson Process Management, Endress+Hauser, Krohne, Pepperl+Fuchs, Phoenix Contact, R. Stahl, Rockwell Automation, Samson, Siemens, Vega and Yokogawa. In total, three organizations and 12 industry partners working on Advanced Physical Layer for Ethernet.

Addressing the barriers

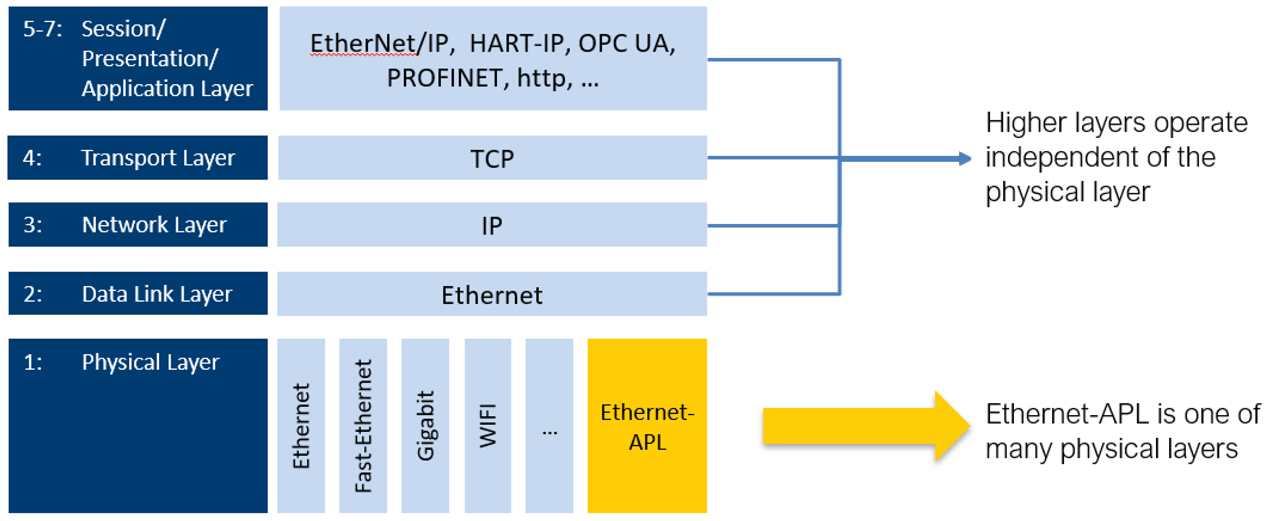

ISO OSI model shows independency of Ethernet-APL from higher layers.

The requirements of process industry, even for future system concepts are identified and clear. To fulfill all requirements, several specifications need to be enhanced. The request was addressed to the appropriate organizations.

IEEE 802.3cg

Main aspect to fulfill these requirements is a new physical layer based on Ethernet technology. Therefore, the request was raised at IEEE 802.3 to work on a specification for 2-wire Ethernet with 10Mbit/s to achieve long-reach applications and power and data over the same twisted-pair Ethernet cable.

In 2016, the IEEE Standards Association approved the IEEE 802.3cg project. The specification was finalized end of 2019 and released beginning of 2020. Based on this specification, manufacturers of PHY chips can start to produce the required Ethernet PHY.

IEC 60079

To fulfill the requirement of intrinsic safety for loop-powered and separate powered devices in hazardous areas up to Zone 0 / Class 1 Division 1, IEC PT 60079-47 project team within technical committee IEC SC 31G is working on a technical specification for the 2-Wire Intrinsically Safe Ethernet (2-WISE) in IEC 60079. The focus is to create a concept for ignition protection.

In the meantime, the working group agreed that the principals defined in Fieldbus Intrinsically Safe Concept (FISCO) are also suitable for the 2-WISE technical specification, including some adaptions for the new physical layer. The perception is supported by successful tests executed at DEKRA Testing and Certification GmbH. The final technical specification (IEC TS 60079-47) is expected by the end of 2021.

Finally, the Ethernet-APL definitions must be considered in the relevant specifications of the organizations FCG, ODVA and PI. These adaptions are expected to be finalized by the end of 2020.

Basic definitions for Ethernet-APL

ISO OSI model: As named, the Ethernet Advanced Physical Layer is an additional physical layer based on IEEE 802.3cg. Therefore, the Industrial Ethernet protocols like EtherNet/IP are independent of this enhancement as they operate independent of the physical layer.

Topologies: By Ethernet-APL, already established topologies can be realized. This includes the proven trunk-and-spur topology of fieldbus infrastructures with the ability to power up to 50 field devices with up to 500mW each. The installation of both APL field switches and APL field devices in hazardous areas with intrinsic safety is ensured.

Advantages from a customer point of view: Ethernet-APL provides many advantages for planners, engineers and maintenance staff.

Reduction of system design and integration time: By having one pervasive communication technology between field level and control level, gateways and proxies that convert different communication protocols are not required in an Ethernet-APL system infrastructure. Due to power supply output up to 60W, more devices per power supply can be added which leads to fewer segments. The well-known trunk & spur topology can be adapted by Ethernet-APL systems. In addition, pre-existing installations can be replaced easily by re-using fieldbus cables. In total, the complexity of the system design is reduced.

Reduction of startup efforts

During installation of an Ethernet-APL infrastructure, less installation errors might occur due to polarity independence and the common trunk & spur topology.

After installation, test efforts are lower as the physical layer in an Ethernet-APL infrastructure is always the same. Same applies due to power and data on the same cable which occurs in the minimal amount of wiring.

Even for training purposes, the effort decreases as there is only one communication in all network levels. By standard means for IP based communication which is supported by auto-instantiation, the vertical integration of OT in IT can be done easily.

By high data transmission rates which is up to 300x faster than traditional systems, fast device configuration is supported.

Timeline

As already described, all relevant specifications are expected to be finalized and released by the end of 2020. The objective is to demonstrate Ethernet-APL with real products of the complete network infrastructure at Achema fair (Frankfurt, Germany) in June 2021.

First customer experiences

In 2019, the Ethernet-APL technology was evaluated in a chemical plant in Germany based on first prototypes. Focus of the evaluation project were the already described requirements of process industry:

- One Ethernet protocol for all applications

- Robust Ethernet communication over all automation levels

- Data communication and power supply over the same 2-wire cable (reuse of fieldbus cable)

- Usage in hazardous areas

- Parallel data access for IIoT use cases according to NAMUR architecture: The evaluation project was executed in a realistic set-up including a control room and a field.

First results of the experiences were presented during the NAMUR General Assembly in November 2019. Summarized, the evaluation was successful, and the technology offers the advantages that were expected.

Further customer evaluation projects will provide an ability both to receive feedback for the technology and for creating more awareness, evaluation projects based on prototypes are planned by industry partners with suitable customers in different industries.

Digitalization in safety applications

With Ethernet-APL, the vision of a single network for all automation levels becomes reality. But what about safety applications?

The number of safety-related measuring points is increasing which enforces this question. In terms of the single network vision, also safety applications shall be ready for digitalization. By considering the safety protocol CIP Safety for EtherNet/IP, exactly this use case fulfilled.

Process Automation – DIM

Ethernet technology will be the key to get access to data from smart instruments. In combination with PA-DIM, which is currently in development, new possibilities for future digital services are achieved.

PA-DIM offers the realization of these digital services as it is defined independently of manufacturers, protocols and platforms. This device information model is based on OPC-UA and is transferred based on TCP via Ethernet.

Basically, PA-DIM consists of a unified device information model which defines the semantic of data to avoid the interpretation of data.