TechnologyMarch 21, 2023

2023 Time-Sensitive Networking Technology Update

Industry experts provide their perspective on the megatrends and technology shaping the development of Time-Sensitive Networking (TSN) applications. The lure of the technology continues to the convergence of IT-OT applications on a single network especially in tandem with high-speed, Industrial Ethernet networks.

Time-Sensitive Networking (TSN) continues to move forward offering the elegance and simplicity of a single network, solutions for IT-OT convergence and the fulfillment of IEEE/IEC 60802, backed by the collaboration efforts of a wide range of industrial companies.

In this special report, the Industrial Ethernet Book reached out to industry experts to gain their insights into the technology megatrends driving Time-Sensitive Networking, the possibilities of new applications and the challenges for automation engineers.

Evolving TSN Landscape

Key automation building blocks and software integration needed.

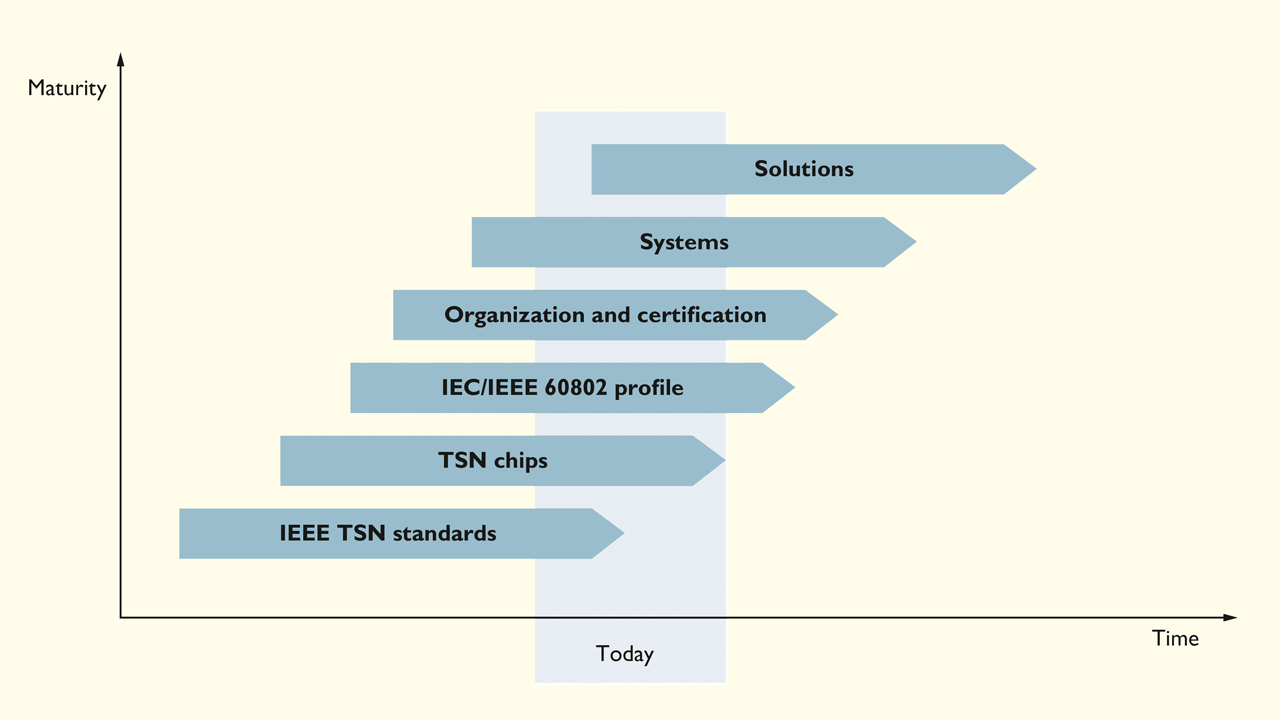

According to Gunnar Lessmann, Master Specialist Profinet and TSN for Phoenix Contact, the continuing emergence of TSN will require industry developments at many levels.

“The enabling of TSN requires Ethernet hardware and software that supports the necessary IEEE standards. We can see that many chip manufacturers are integrating TSN capabilities into new and already existing devices,” Lessmann said. “These new building blocks still need to be integrated into new versions of automation products by device manufacturers and finally tested and certified before they can be used in OEM automation Solutions.”

He said that, in addition, the “industrial middlewares” such as PROFINET or OPC UA need to support TSN. Based on this model, in 2023 each middleware has its own “roadmap” regarding TSN.

“Each point of these is complex and represents a challenge for large scale market adoption. But all items are addressed and under work in the responsible organizations,” he said.

TSN technology focus

When asked about what specific application areas or markets are a fit for TSN, Lessmann responded that a specific application or market for TSN cannot be identified. Basically, all applications are candidates for TSN that benefit from high determinism and bandwidth, short cycle times, synchronization, and IT/OT convergence in a single network. This goes from industrial image-recognition and processing over motion-control to energy management in substations.

Thanks to IEEE-standardization of TSN, all these applications can be solved with the same hardware and may differ only in software support. But it still offers significant potential benefits for smart manufacturing.

“The biggest advantage of TSN is the so-called convergence of IT and OT applications in just one network. This is especially valid in combination with link-speeds of 1Gbit/s or more,” Lessmann said.

“TSN allows the combination of functions from classic high-deterministic fieldbus systems and IT applications like large data transfer in one network. Today separate networks for IT and OT are used in many applications leading to higher device and installation costs, know-how, etc.,” he added.

As far as the expected impact of TSN, Lessmann offered a different perspective.

“Let me explain this with an example from industrial image processing. A synchronized Ethernet camera captures images during the running process. The image data is transported deterministically to a controller and processed in real time. Then, depending on the result, actuators such as valves or drives are controlled, which act synchronously on the running process. In addition, the actuators and the camera provide further information about themselves and other process parameters that enable predictive maintenance in the “cloud,” Lessmann said.

“With TSN, all this is possible in one network with just one planning, installation and operational support. Furthermore, classical digital process-sensors may be reduced. The configuration can also be changed during operation without influence on other devices. TSN in applications such as these enable significantly higher flexibility,” he concluded.

TSN Technology Advances

Focus on industry collaboration, QoS Ethernet and TSN-enabled applications.

Georg Stöger, Director Training & Consulting along with Alexander Damisch, Vice President Dependable Networks for TTTech, together responded to our questions about continuing developments with Time-Sensitive Networking.

Their viewpoint is that, although TSN has still not been widely adopted in automation products currently available on the market, three very significant advances are enabling further and faster adoption. Here is a summary of those advances.

#1 – An industry-wide collaboration group (TIACC, https://www.tiacc.net/ ) for ensuring conformance of industrial TSN components according to the IEC/IEEE 60802 profile has been established. Industrial networking consortia that have announced the adoption of TSN – including OPC UA FLC, PROFINET, CC-Link, ODVA – are joining forces with the Avnu Alliance to define a common conformance test plan for TSN capabilities.

This will ensure that industrial TSN networking components will work seamlessly together, both in applications where TSN is used as a high-performance extension for the existing industrial networking technologies and in more integrated, converged architectures where several previously competing industrial networking technologies co-exist.

#2 – TSN is increasingly established not just as QoS improvement for Ethernet, but as base technology for a dependable communication sublayer for application layer technologies, including OPC UA, the Open Communication Framework (OCF) of the Open Process Automation Specification (OPA-S), and DDS.

#3 – As vertical market-specific profiles and TSN enabled hardware become state of practice, a more software-defined world is emerging, where software stacks and tools to support deployment of TSN enabled applications and products are being developed.

Stöger and Damisch added that there are several “philosophies” on how to apply TSN to industrial applications.

The conventional “system builder” approach results in a fully engineered network, and TSN is a great fit for this kind of approach because it provides mechanisms to statically configure a multitude of networking services and robust delivery.

- The “plug and produce” approach adds a dynamic element of run-time reconfiguration to the mix, but still requires that the network performs deterministically like an engineered OT network after each reconfiguration. Again, TSN is a great fit for this use case.

- For IT-centric (non real-time) applications, which are probably managed with containerization and orchestration and operate as webservices, TSN supports the flexibility and performance of QoS Ethernet.

- The unique application area for TSN is when all these paradigms need to be combined, i.e. when a system contains statically configured, robustly isolated networking functions for OT applications, but also requires dynamic, flexible reconfiguration and adaptation during runtime to support “plug and produce” as well as edge computing and connectivity to the cloud with containerized, orchestrated web services.

“We expect that systems of this kind will become more prevalent due to industrial IoT and edge computing trends. TSN will then act as ‘IT-OT software-defined network infrastructure’; interaction with the network configuration management services will be handled by application layer services such as OPC UA FX, DDS, and Kubernetes,” they added.

When asked about specific application benefits that TSN provides, they offer three specific areas:

Higher, faster, further

Probably the least surprising benefits of TSN versus classic fieldbus technologies based on 10/100 Mbit/s Ethernet are the incremental performance gains that the technologies in the “TSN toolbox” can provide for automation applications – higher communication bandwidth, lower communication latency. This is mainly relevant where existing applications could not be scaled because of technical limitations.

Wired-wireless network architectures with unified management

The tighter integration of TSN with 5G wireless networking technologies and layer 3 enhancements (IETF DETNET) to provide consistent networking quality of service (QoS) and synchronization services across a complex automation plant/system with wired and wireless domains.

Communication services with defined QoS for applications distributed across several such domains can be established and managed without having to configure and manage the individual network controllers separately. Dynamic network reconfiguration, which would otherwise be very complex and possibly subject to vendor-specific tools, will become a standard service.

Industrial edge computing architectures

The co-existence of OT applications (IEC 61131, 61499) with reliable real-time communication requirements, IT/cloud applications and networking protocols in a converged infrastructure is becoming reality. This means virtualized and containerized applications will be managed more and more by agile delivery of services and applications. While the app is becoming software-defined, making sure applications can be developed independently of their physical deployment, software-defined networks (SDN) are needed to ensure the Quality of Service (QoS) of the production and consumption of the data the applications need. These highly configurable QoS and determinism needs from the network are all key capabilities provided and guaranteed by TSN.

As far as the expected impact that TSN technology will have on smart manufacturing, and the general timeline for these innovations, they concluded that, as noted above, we expect that TSN facilitates integrated IT-OT edge computing architectures, also for smart manufacturing.

“As a technology provider, we cannot speak to the specific impact and timelines that our customers envision for their manufacturing systems, but for companies who want to influence the standards and reference architectures, now is the time to get involved.”

Convergence and Unification

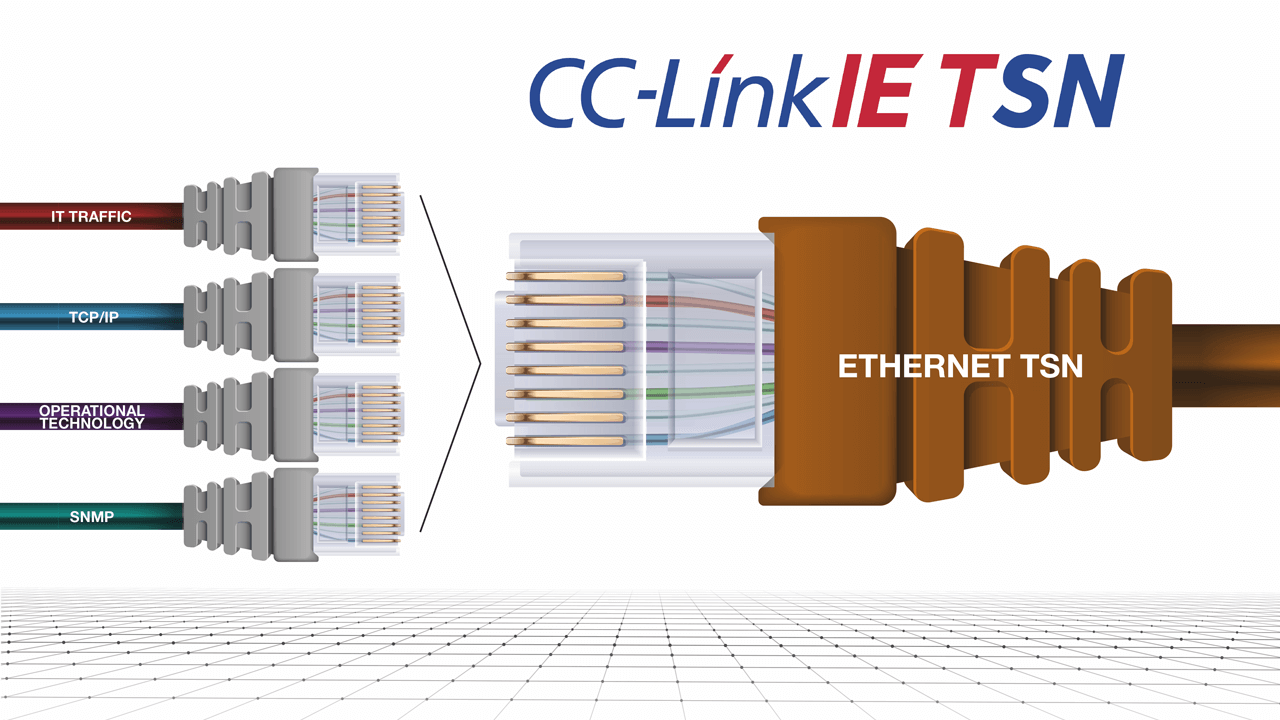

Different types of traffic on a single network.

Thomas Burke, Global Strategic Advisor for the CC Link Partner Association, said that Time-Sensitive Networking technology is moving ahead with sweeping changes that are impacting automation and machine control networking.

“The industrial communications landscape has dramatically changed over the years. I remember when Ethernet was first coming into the factory, and it took a while to be successfully understood that this was the right technology for factory and process automation,” Burke told IEB.

“The value of TSN is it’s clearly about the convergence of networks and the ability to have multiple industrial Ethernet networks running on the same physical wire. But what customers are realizing with the value of the technology is the fact that they can perform control applications simultaneously and be able to configuration applications – plus they can have other applications and devices like printers and cameras on the same wire without affecting control.”

Burke said that things like safety and motion are commonplace on industrial Ethernet networks and the fact that it will be able to add new devices to the network while the network is being used for control applications will make the life of everyone much easier. There are a multitude of opportunities that can leverage the deterministic performance and the ability to address digital transformation and IT to OT conversions that TSN technology provides. Safety and security are critical components that automation applications clearly need.

TIACC Collaboration

Industrial Ethernet organizations are working closely together and have formed a partnership to validate the technology known as TIACC (TSN Industrial Automation Conformance Collaboration).

“The challenges of adoption are the concerns of the manufacturing community as to how they support all these legacy devices that are currently running on their own different industrial Ethernet networks,” Burke said. “Clearly, we will need the necessary bridges and gateways and switches that will enable the existing devices and networks to coexist with this great new TSN technology.”

He added that the beauty of the TSN technology is that there is no application area or market that cannot benefit from this transformative technology.

“TSN truly is a game-changing technology because it allows high speed performance deterministic operation and supports convergence of the different industrial Ethernet networks coexisting on the same physical wire,” he said. “But if you think about markets specifically that are recognizing the benefits, you will see that automotive, pharmaceutical, oil and gas, water treatment, food and beverage, and the semiconductor industry all will benefit with dramatic increases in the capability and the beauty of being able to support complex applications in this new digital transformation. We will now be able to have data analyzed from many disparate devices and disparate networks and convert it into useful information for the IT world — and all existing on the same physical wire.”

He said that one area that will see a significant benefit in the one-wire concept is robotic applications. Robotics has been preaching single-payer Ethernet for a long period of time and coupled with power over the data line and TSN technology, nothing won’t be able to be accomplished. But he added that the technology also really supports the concept of quality of service. This is a significant value to TSN technology and will allow support for existing devices coexisting. Although, it will not have the same benefits of the quality of service that you have in a TSN network.

“Determinism has always been a benefit of the existing industrial Ethernet networks, but now with TSN it takes it to the next level. IEC/IEEE 60802 is an evolving standard where the focus is changing the world in comparison to standard un-minified Ethernet,” he said.

His view is that there are so many technical benefits and technology changes that should be easily adopted by suppliers rolling out TSN products. Typically, networks have been underutilized but now with the new volume of devices, people are starting to realize they need connectivity and higher speed networks, which will give us the capability of better utilization and performance along with the coexistence of multiple networks running on the same wire. Clearly, we can have universal quality of service and fault tolerance now being built into the industrial Ethernet protocol when leveraging TSN technology.

TSN application benefits

Burke said that TSN’s specific application benefits are clearly that the automation industry — both process and discrete — really wants complete solutions from top to bottom and to be able to have IT and OT applications share data and information in a bidirectional fashion.

“The fact that there is a push for this whole new digital transformation and making use of complex information data models is driving the adoption and need for TSN technology,” he said. “There’s a lot more data and information that can be leveraged with this new strategy and specifically how you can have ‘plug and play’ when adding new devices on a network without affecting the existing control applications running simultaneously.”

A driving force is that there are a multitude of vendors that are building TSN technology on a chip, which will really facilitate adoption of the technology. So, the business value is clear that there is significant value in the increased determinism and performance on this new converged technology and it’s driving new vendors to look for opportunities to become the toolkit vendors to really help companies adopt the technology.

“The standardization of TSN and the standardization of these different data models really brings the digital transformation to reality. There have been a multitude of information model organizations that all were operating independently and you’re going to start seeing the ability to have all of these different devices and applications leveraging these standardized information models because of the increased network bandwidth of the TSN technology,” Burke said.

The industrial Internet organizations are rapidly working to develop their corresponding industry standards to embrace TSN technology. CLPA released CC-LINK IE TSN in November of 2018 officially. The significance of this was they recognized that the technology of TSN was evolving but they could still put a stake in the ground to help the end users through the development of products by suppliers to achieve and begin their journey in support of smart manufacturing.

CC Link IE TSN brings together IT and OT communications.

TSN developments

Burke said that recently a number of the other industrial Ethernet organizations have been rolling out their TSN-based standards to help their suppliers bring TSN products to market. Success is measured by the level of adoption of technology and clearly there are a multitude of vendors that are actively developed or have already released products supporting the TSN technology in their products.

“The industry is ready for the technology, but it takes time for the major automation players to roll out a complete portfolio of their products supporting this brand-new technology. Some of the automation players, like Mitsubishi Electric Automation, have already rolled out all of their products supporting TSN technology. Mitsubishi Electric Automation also recognizes the need to have all of the industrial Ethernet networks supported with their product portfolio, as well as a number of the other major automation suppliers all support multiple industrial Ethernet protocols from a connectivity solution with their products either natively or through third-party products that provide the gateways to other networks,” he said.

“So, the simple answer is it takes a while to have native adoption of these important evolving industry standards but in the meantime there’s the ability to have connectivity and leverage TSN technology through interim product solutions. We will always have a multitude of process and discrete operations that will have an existing system of different devices and networks that will need to be bridged into this new technology. Many manufacturers are developing products that will allow this new TSN technology to coexist with all of the legacy devices and networks already installed,” he added.

“I like to compare TSN with a large selection of spices, which are delivered without a recipe. IEEE doesn’t even claim to specify how the technologies should be used. And it is now up to the cook what he makes of it. And just as a dish is not just spices, TSN is not a communication solution or industrial Ethernet system.”– Martin Rostan, Executive Director, EtherCAT Technology Group.

Not a Comprehensive Solution

Biggest benefit of TSN is level above real-time control, for synchronization of network controllers.

Martin Rostan, Executive Director for the EtherCAT Technology Group, told IEB that TSN technology advances have been slower than many anticipated, and its strengths are not at the real-time control level but instead the level above the controller.

“We continue to hope that TSN technologies will be suitable to cost-effectively realize vendor-independent real-time features at the controller-to-controller communication level and above,” Rostan told IEB recently. Cost-effective in that TSN technologies will become commodity and supported by all commercially available Ethernet switches and chips – not just dedicated devices and chips for the automation industry. Vendor-independent in that common approaches to configuration are becoming prevalent.”

He added, however, that development continues to be delayed, and it is already clear that TSN technologies are unlikely to live up to expectations.

“Contrary to what was expected years ago, TSN is not gaining acceptance in general IT applications, and there is unlikely to be a general approach for heterogeneous automation networks that is independent of manufacturers and fieldbus technologies. This means that TSN will establish itself in some isolated solutions, but will not become the comprehensive solution that many are hoping for,” Rostan said.

According to Rostan, at this point it must be said again that there is no such thing as “the TSN” or “the TSN technology”. He added that the TSN Task Group of the IEEE is working in more than 40 projects on a variety of technologies, not on one.

“I like to compare TSN with a large selection of spices, which are delivered without a recipe: IEEE doesn’t even claim to specify how the technologies should be used. And it is now up to the cook what he makes of it,” Rostan said. “One uses only a few selected spices, the other prefers others, or many more. And so the dishes that are created with the same set of spices differ massively. And just as a dish is not just spices, TSN is not a communication solution or industrial Ethernet system.”

He said that Time-Sensitive Networking can be used by such systems to improve their availability or their real-time properties. Even the joint “60802 working group” of IEC and IEEE, which deals with the application of TSN technologies for the automation industry, does not have the goal of creating the TSN cooking recipe and thus interoperability – here it is “only” about co-existence of many different “TSN recipes”. Therefore, the question of “unique solutions” is correct; there will be several TSN recipes that are incompatible with each other, which in the best case can co-exist on the same network.

“The idea is to use TSN technologies to improve the real-time properties of communication between controllers, while at the same time providing bandwidth for non-real-time communication,” Rostan said. “No market-ready solution is yet within reach, and it remains to be seen what it will look like – and how complex the configuration will be, and what it will cost. And unfortunately, the solution will probably not be vendor-independent.”

Rostan concluded by stating that real-time communication has the greatest impact on smart manufacturing at the level below the controller: i.e., in the communication from the controller to its sensors and actuators.

His view is that TSN-based approaches will not have any advantages over the much simpler and more powerful EtherCAT Device Protocol.

“At the level above the controller, where TSN technologies belong, we hope for better synchronization of networked controllers. This will probably be possible in a few years, but I don’t expect it to become widespread: the applications that will significantly benefit from it are not numerous enough,” he said.

IEEE/IEC 60802

Different types of traffic on a single network.

According to Dr. Al Beydoun, President and Executive Director at ODVA, TSN is enabling technology in the development of advanced automation application solutions in 2023 although he see challenges to large scale adoption.

“IEEE/IEC 60802 Time Sensitive Networking (TSN) will make it possible to have different types of traffic running on a single network with priority applied to each message that will ensure that the most critical information arrives on time, such as safety packets, with other less important information, like routine diagnostics, arriving with a delay, if needed,” Beydoun told IEB recently.

“This also opens up the door for multiple communication protocols to run on a single network with fair quality of service, depending on the message type and priority. The ability to include many different types of devices, such as machine vision, surveillance cameras, safety light curtains, and more, on the same network will simplify planning and make it easier for data to flow from the plant floor to the controller, edge, and the cloud. 60802 TSN will also enable additional devices to be added to machines after initial commissioning without degrading network performance or impacting existing devices.”

Beydoun said that challenges related to large scale adoption of 60802 TSN include development of the prioritization mechanisms that will need to be configured within switches across the broader network to ensure appropriate quality of service is applied to each packet during transportation.

“Without software configuration tools that allow for centralized commissioning diagnostics, and configuring network changes for all different types of traffic regardless of protocol, device type, or vendor, the value of TSN is significantly reduced and other solutions, such as simply increasing the overall bandwidth, become more practical,” he said.

Additionally, since the IEC/IEEE 60802 TSN specification hasn’t been finalized yet, there are risks to installing TSN devices too early in case there turn out to be interoperability issues with devices that don’t adhere to the final specification.

TSN application solutions

Artificial Intelligence (AI) neural networks and Machine Learning (ML) algorithms that rely upon camera images and training models to identify quality defects compared to the desired output are a potential use case for TSN. Over time, higher resolution images, additional camera angles, or an increased number of images could be transported over the network to help the algorithm improve quality with additional input.

Beydoun said that TSN would ensure that the critical information on the network would be able to continue to arrive when needed despite any increases in the amount of data relative to total bandwidth. Another possible use case is the transport of different communication protocols through the network to a consolidated edge device for upload to the cloud. While this data wouldn’t be used for control, it would be important to ensure that it didn’t interrupt other critical control traffic on the network.

“Network performance issues can be ameliorated today, for example, by increasing the total bandwidth or by identifying the root cause of the traffic bottlenecks and working to remove them via network segmentation or the addition of network switches to filter unnecessary traffic,” he added.

Properly configured 60802 TSN networks would be able to simply prioritize the most important safety and I/O traffic while allowing other diagnostic and non-time critical packets to wait until the pipeline is freed up. One of the advantages of 60802 TSN is that you can take a network that would have otherwise had an unacceptable amount of jitter, latency, and lost packets due to peak traffic exceeding the available bandwidth and transform it to a reliable network by prioritizing critical messages and having lower priority messages wait until traffic clears up.

Looking ahead

Beydoun said that 60802 TSN will make it easier to host converged networks with different communication traffic types, and potentially even protocols, assuring a high degree of availability for critical messages resulting in dependable network performance. Additionally, 60802 TSN networks will have the advantage of being capable of accepting additional devices on the network in the future with known impacts on performance. 60802 TSN will also help prepare for future solutions, such as AI, that can bring valuable new approaches to the table that can optimize production, but could also add additional data transportation requirements over time to existing networks.

“Once the IEC/IEEE 60802 standard is published, ODVA will finalize and publish a Common Industrial Profile (CIP) Application Profile to make 60802-enabled TSN an option for new EtherNet/IP devices either natively or via a gateway. EtherNet/IP is anticipated to have an 60802 TSN compatible specification available as soon as is practical after the IEC/IEEE 60802 TSN specification is released,” he stated.

Time-Sensitive Networking is enabling technology for the Automation Model of the future.

TSN Profile for Industrial Automation

Large-scale adoption may be linked to working group’s conclusions.

“The Institute of Electrical and Electronics Engineers (IEEE) finished the basic standardization of TSN some time ago.” Phil Marshall, Chief Operating Officer at Hilscher North America told IEB recently.

“However, it consists of a set of standards that cover a range of real-time requirements across a diverse array of markets including automotive, medical and industrial. This makes it necessary to agree upon a base set of parameters and definitions for how TSN should be utilized by each industry,” Marshall said.

He added that an International Electrotechnical Commission (IEC) 60802 working group has taken over this responsibility and has been tasked with determining a “TSN Profile” for industrial automation. Their latest draft, version 1.4, was released in July 2022 with ongoing discussions continuing.

“We will have to wait and see how large-scale adoption plays out based on this working group’s conclusions,” Marshall said.

Looking at TSN applications

According to Marshall, TSN is a rule-set that decides how traffic transmits through Ethernet networks in a deterministic way. It also minimizes jitter. Its intention is no different from any existing standards. As an IEEE standard, it is not driven by individual firms and therefore has the potential to harmonize layers two and three of the Open Systems Interconnection (OSI) model in industrial communications.

This standard also has unlimited media compatibility, allowing TSN to use Single Pair Ethernet (SPE) or even 5G for data transmission. TSN transport mechanisms are pictured in the graphic above.

“TSN’s time synchronization and real-time mechanisms allow designers to cluster controls based on Gigabit Ethernet, which enables more complex automation systems. For applications in general, both accuracy and control complexity will increase,” Marshall said.

“Depending on how the standardization evolves, it may become feasible to connect different machines from different vendors. In terms of network topologies, another possible benefit is to combine the OPC UA Publish-Subscribe mechanism with TSN to facilitate a common data model between the field and the cloud,” he added.

His assessment is that TSN is a technology with huge potential because it will enable more complex control and massively extend the capacity to address current industry challenges in asset management, remote monitoring and diagnostics, edge computing and cloud-based architectures as well as applications. However, market assessments widely differ in their predictions of business and adoption times.

Hilscher expects to see a wider usage of TSN-based controls and devices from 2025 onwards.

“As an industrial automation “enabler” company, we are following developments closely. TSN-based equipment for 100-Mbit applications is already available today, and our future generations of Gigabit devices will unlock the full potential of TSN whenever the market demands it,” Marshall added.

Al Presher, Editor, Industrial Ethernet Book