TechnologyMarch 17, 2022

Getting TSN products and solutions to market

To enable futureproof industrial communications and next-level performance, automation vendors need to act now to deliver TSN-compatible products or upgrade existing devices with TSN capabilities. Doing so will help customers create factories of the future and enhance their competitiveness in a fast-growing market.

Time-Sensitive Networking (TSN) is an innovative technology solution for Ethernet-based industrial communications that can support smart operations within current facilities as well as tomorrow’s Connected Industries.

How can automation vendors deliver advanced solutions that leverage this technology? What do they need to consider in order to create successful, highly competitive solutions?

This article provides an overview of the CLPA TSN development ecosystem, what solutions can be used and how to integrate TSN-compatible functions in existing devices using conventional industrial Ethernet. It offers recommendations for industrial automation device manufacturers on the successful implementation of TSN and delivery of key solutions for future-oriented applications.

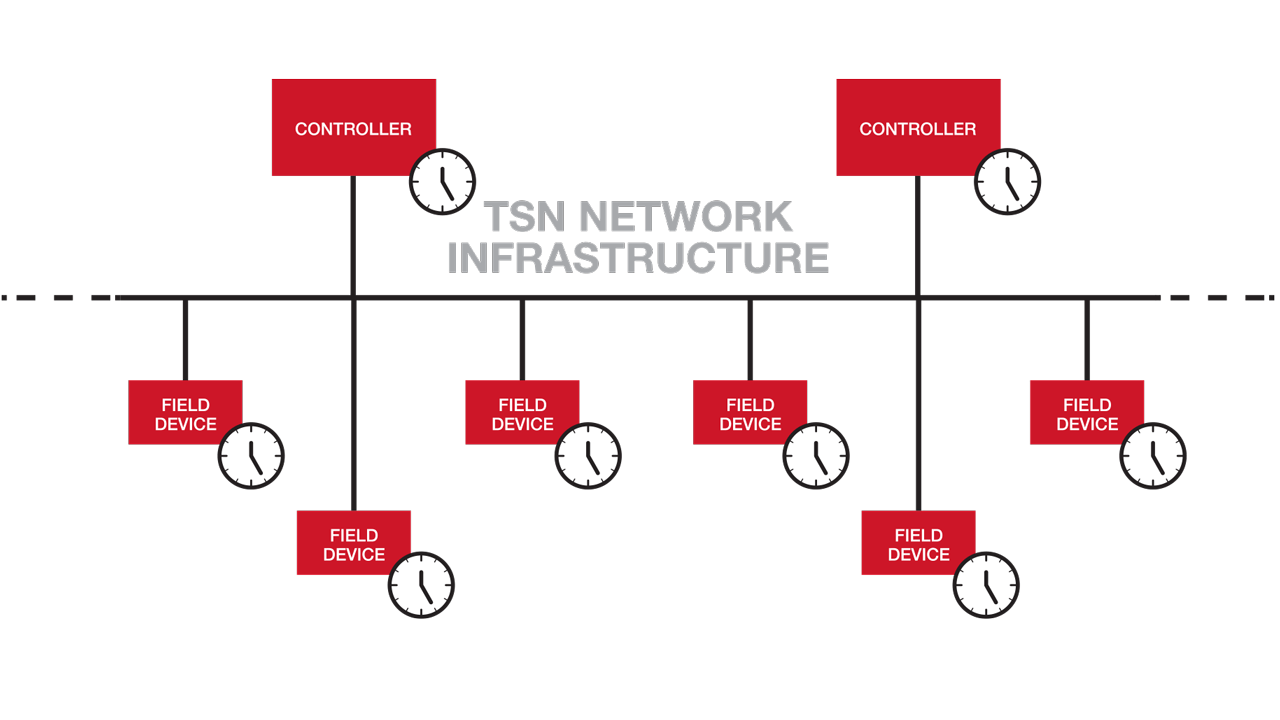

By using IEEE 802.1AS, all devices on the network have a shared time reference. This provides deterministic communications by controlling latency and jitter.

TSN functionality

The two core benefits offered by TSN are determinism and convergence.

Determinism is fundamental to supporting time-critical communications on the factory floor, as it ensures the predictable delivery of data by minimising latency and jitter. This, in turn, supports real-time applications and provides the foundation for convergence.

Convergence, the second key ability of TSN, enables companies to merge different traffic types onto a single network without affecting the performance of shop floor communications. This is fundamental to sharing operational insights and hence increasing process transparency across an enterprise, which can then be used to derive insights to optimise manufacturing facilities and entire organisations.

Since TSN is an extension of standard Ethernet, it is also interoperable with existing network technologies and devices. Hence it can be used alongside existing devices, reducing system investments. In order to harness the full potential of TSN, it may be beneficial to consider a hardware-based solution.

While this route may require more investment and development time, the benefit is a more competitive product and longer lifecycle. Several different solutions are available, enabling vendors to select the right platform for their needs.

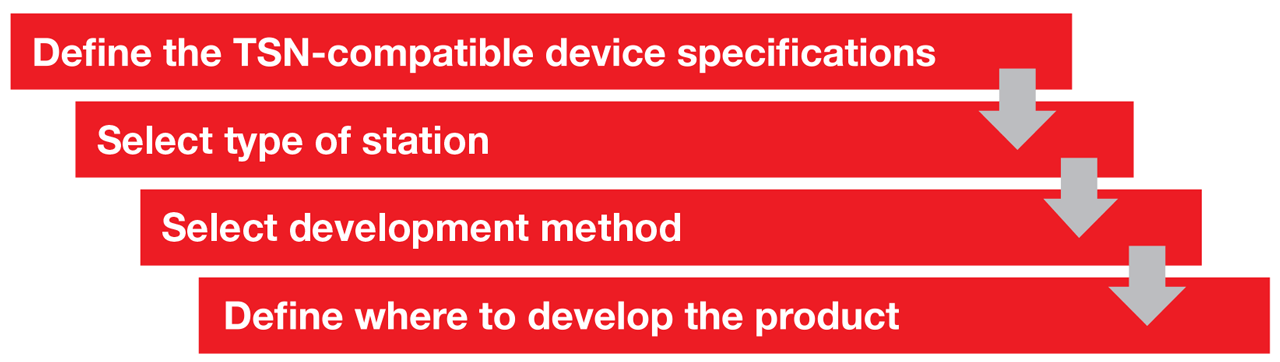

Product development workflow summary.

TSN development workflow

It is clear why offering TSN-compatible products is highly beneficial for automation vendors. To successfully develop devices that provide added value to end users, it is necessary to consider the capabilities, performance and nature of the products themselves from the outset.

First, companies need to clearly define what the product should be able to do. This will determine the type of station that is to be developed, such as master or remote. Also, the required performance level, in terms of speed and synchronisation accuracy, needs to be decided. Once features are set, vendors can look for existing products that may be suitable for an upgrade to deliver TSN functions.

Businesses then need to select the most suitable development method for the TSN device that they are producing. The decision should be based on the pre-identified performance requirements, along with a consideration of the suitability of their existing development methods.

Another key decision that companies need to make is where to conduct the product development activities. Should these be carried out using in-house resources? Or is it best to rely on a specialist contractor?

Once the TSN device is ready, it also needs to be certified in order to prove that the necessary technology requirements are met. To do this, vendors should undertake relevant third-party certification. This offers an independent assessment of the communications performance that can offer extra assurance to customers.

When all these tasks have been completed, the TSN-compatible device can be introduced to the market.

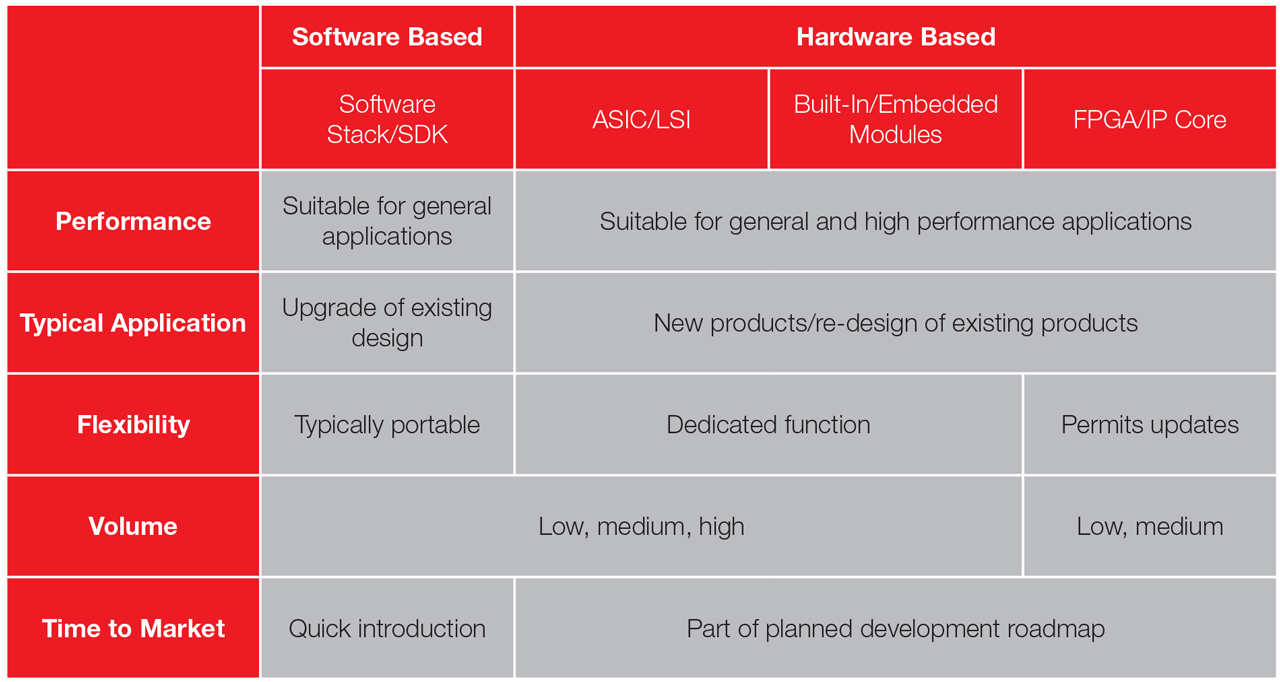

Comparison of development methods.

TSN development methods

In order to implement TSN for industrial communications, end users and OEMs need both a suitable network technology as well as automation devices that can support this technology’s capabilities. This need is met by vendors offering innovative products, which address customers’ needs while increasing their competitive advantage in the marketplace. In general, to minimise costs and time to market, a vendor will look to use their existing platforms and tools where possible to develop these products.

Hence it is important that the type of industrial Ethernet technology used offers an open development ecosystem that includes options that match the vendors’ existing methods. The broader the range of options, the better chance there is of catering to the needs of the most vendors. Typically, this means there should be both hardware and software solutions in addition to different bandwidth options, such as 100Mbit and gigabit.

Each development method will offer different advantages while perhaps being more suited to one application or another. It is therefore important for developers to know what options are available and how they might fit with their existing designs and hardware architectures.

Deciding what kind of TSN product to develop

The first consideration that vendors should take into account is to decide what type of device network functions they want to support, i.e. what is the role of the end product within a network. In the context of this article, this means master, remote or local stations.

Masters manage networks by controlling the traffic of other stations. This may include cyclic (synchronous) and transient (asynchronous) transmissions. Typical master devices include PLCs and industrial PCs.

Remote stations, conversely, are overseen by masters and represent field devices, such as I/O, valve blocks, HMI, inverters and servos. They can perform 1:n cyclic and transient transmissions with other stations. Transient communications are handled by client/server functions.

Local stations are often PLCs or industrial PCs. They can perform n:n cyclic transmissions with themselves and the master. They can also perform 1:n cyclic and transient transmissions with other stations. Transient communications are also handled by client/server functions.

Vendors should also consider whether they want to develop devices for motion or safety applications. The first typically require full TSN support to provide the necessary axis synchronisation capabilities. This can typically deliver microsecond synchronisation accuracy as would be required in demanding applications such as a printing press.

Safety devices are another key market area that can also be served by TSN networks. One implementation method is to use a software stack combined with a safety stack to provide a “black channel” approach.

Third-party testing to validate performance is an important part of the development of TSN products.

New design or migrate existing products?

Once the type of station has been selected, vendors should decide if they should add TSN capabilities to an existing product, or if new product development will be necessary. In the case of a new product, after taking market requirements into account, a specification that fixes what the new TSN-compatible products should do, the capabilities they should offer and the investment required to implement this is essential. These elements are key to defining the performance, ease of implementation and time-to-market.

In the case of upgrading existing products, while this may decrease the time to market and investment required, it may also require compromises that may not fully exploit the potential of TSN.

In order to offer further development flexibility, it is possible to decide what level of performance is required. This allows the right balance to be found between device performance, development investment and time to market. One option is to follow a generally software-based approach. This can offer a quick upgrade of existing devices. Thus, it offers a key tool to speed up the adoption of this innovative technology, although the device performance may be lower.

The converse of this is a generally hardware-based approach, which although may require additional development effort, can avoid the compromises in performance that software development may require.

Finally, bandwidth and heat dissipation are key considerations to determine the communication speed. While a gigabit PHY is preferred for best performance, this has to be balanced against thermal considerations, which may be an issue for smaller devices, or those with advanced ingress protection ratings.

Once these decisions have been made, it is crucial for businesses to be able to access a suitable development method, whether software or hardware. Hence selecting a network technology that can offer a comprehensive open development ecosystem is essential.

The following sections explore what development ecosystem solutions and features are available for the creation of TSN-compatible products.

Software solutions

A software protocol stack, or just “stack” is a collection of independent components that work together to support the execution of an application. It can be configured to address the specific needs of a product. In the case of TSN, this should provide support for IEEE 802.1 standards. They generally have low operational overheads, meaning they can run on economical CPUs platforms. These are usually microprocessors or microcontrollers.

Generally, software stacks are compatible with a variety of real-time operating systems, such as RTLinux, VXworks® or µITRON. Nonetheless, device makers should check the specification of the software stack they intend to utilise to ensure compliance.

A TSN stack is typically part of a software development kit (SDK). This is a collection of software development tools, often in a single installable package, that support the creation of the required solutions.

Software methods offer perhaps the fastest solution to provide TSN capabilities to existing products, as they reduce in-house development time and costs for vendors. Furthermore, they are generally portable, so they can be applied with minimal changes. Hence, they offer a versatile solution to businesses interested in quickly implementing TSN.

Hardware solutions

In order to harness the full potential of TSN, it may be beneficial to consider a hardware-based solution.

While this route may require more investment and development time, the benefit is a more competitive product and longer lifecycle. Several different solutions are available, enabling vendors to select the right platform for their needs.

ASIC/LSI

Application Specific Integrated Circuits (ASICs), also referred to as dedicated communication Large Scale Integration (LSI), are integrated circuits made of a “hard-wired” design of logic elements. These can be found with two different structures. One may offer a network interface that includes a switch and possibly one or more PHYs. The other takes this design and adds a CPU.

Built-in/embedded modules

Embedded module solutions, or built-in modules, cover a wide range of devices that usually combine a processor core, such as a microcontroller or a microprocessor, for key operations and a network interface that focuses on data exchange.

Thanks to these features, developers choosing built-in embedded units can benefit from an easy to integrate solution as well as a flexible framework to exchange the network interface to suit specific applications.

FPGA/IP core

Field Programmable Gate Arrays (FPGA) are integrated circuits whose logic functions can be specified via hardware description languages (HDLs), typically VHSIC Hardware Description Language (VHDL) or Verilog. These solutions are based on programmable (and reconfigurable) interconnects that link different configurable logic blocks (CLBs), which are made of basic logical units, known as ‘slices’. These, in turn, typically feature look-up-tables (LUTs), flip-flops (FF), different types of multiplexers and a network of carry logic to implement complex logic functions.

Specialised applications

Developers can also rely on TSN-compatible PC boards to implement key capabilities on industrial/ standard PCs and similar devices within advanced industrial Ethernet networks. This allows the connection of PCs without any special development. This is especially useful in edge computing applications where a PC/IPC may be used as the gateway to higher level IT systems, providing a component of an OT/IT converged system.

Importance of conformance testing

To validate the capabilities of TSN-compatible devices, developers need to conduct thorough conformance testing, i.e. confirm that the product complies with all the requirements of a given network standard and that it is correctly implemented.

By testing the conformity of their products, developers are able to identify performance issues that may prevent correct operation with other vendors’ compatible products or make them incompatible with the relevant communication specifications. This testing gives end users the confidence that the selected automation component will be fully interoperable with all other devices tested and used on the same network.

Third-party certification

Conformance and interoperability testing can be performed in-house by vendors and/or by independent organisations. Since end users usually look for an independent third-party certification, in house testing is generally only used to confirm that a product is ready to be tested by a third party.

In effect, third-party testing provides an impartial and unbiased evaluation from an external source. As a result, it provides a high degree of confidence to end users that they can use the vendors’ products without any problems. On top of these advantages, accreditation organisations tend to have dedicated testing facilities with specialised, state-of-the-art equipment. Therefore, it is possible to conduct advanced assessments using a wide range of instruments that vendors may not otherwise have access to.

Finally, as conformance testing is conducted by a third-party, automation vendors can focus on development activities whilst specialised engineers assess the products. Test engineers are well trained and experienced in compliance and interoperability testing, providing a level of expertise that may be difficult, time-consuming and expensive to match in-house.

Global testing network

Many vendors are global companies that operate development facilities around the world. Sending products to a single location for testing can be inconvenient, due to language, time zones and other issues. Having access to a global network of test facilities increases convenience and can reduce project lead times. It is also critical that a global testing network use standardised testing procedures so that regardless of where a test is conducted, the outcome will be the same.

Industrial Ethernet protocols that support TSN

To quickly deliver innovative TSN-compatible products for industrial automation applications, CC-Link IE TSN offers an open network that combines TSN functions, as defined by IEEE 802.1 AS and Qbv standards, with gigabit bandwidth.

By selecting this solution, product developers can benefit from a comprehensive development ecosystem that supports the creation of master, local and remote stations. In particular, multiple members of the CC-Link Partner Association (CLPA) already offer ways to implement CC-Link IE TSN via software and hardware and more are being added continuously. The CLPA supports vendors by assessing the conformance of their products, ensuring compatibility with CC-Link IE TSN specifications. The organisation offers development support, pre-certification testing as well as actual conformance testing via a global network of certification facilities.

The workflow to achieve the CC-Link IE TSN conformance certification starts with vendors checking the regulations for the conformance test. Based on this, companies can perform an initial assessment in-house. Afterwards, they need to apply for the CLPA’s conformance test. For the organisation to conduct this, vendors send product and a copy of the in-house test report to the selected testing facility.

Upon successful completion of the conformance test, a certificate and report are issued to the company. This then confirms compliance with CC-Link IE TSN network technology. As a further benefit, the product can be included in the CLPA’s online catalogue, making it visible to customers worldwide. Joint promotion with the CLPA is also possible.

Conclusions

TSN is a key enabling technology for the digital transformation of manufacturing, and can offer key benefits for end users and OEMs:

- Simpler network architectures/machine designs

- Greater process transparency and better management

- More productivity

- Better integration of OT and IT systems

To enable futureproof industrial communications and next-level performance, automation vendors need to act now to deliver TSN-compatible products or upgrade existing devices with TSN capabilities. By doing so they can help their customers to create the factories of the future whilst enhancing their own competitiveness in a fast-growing market.

Special TSN Supplement Sponsored by the CLPA

Getting Your TSN Product to Market

CLPA Technology White Paper

The full “Getting Your TSN Product to Market” white paper discusses the importance of TSN and why device vendors should be considering adding it to products. It describes what development methods are available and details on how TSN functionality can be integrated into products.

Download White Paper