TechnologySeptember 22, 2019

Migrating to TSN-based networks of the future

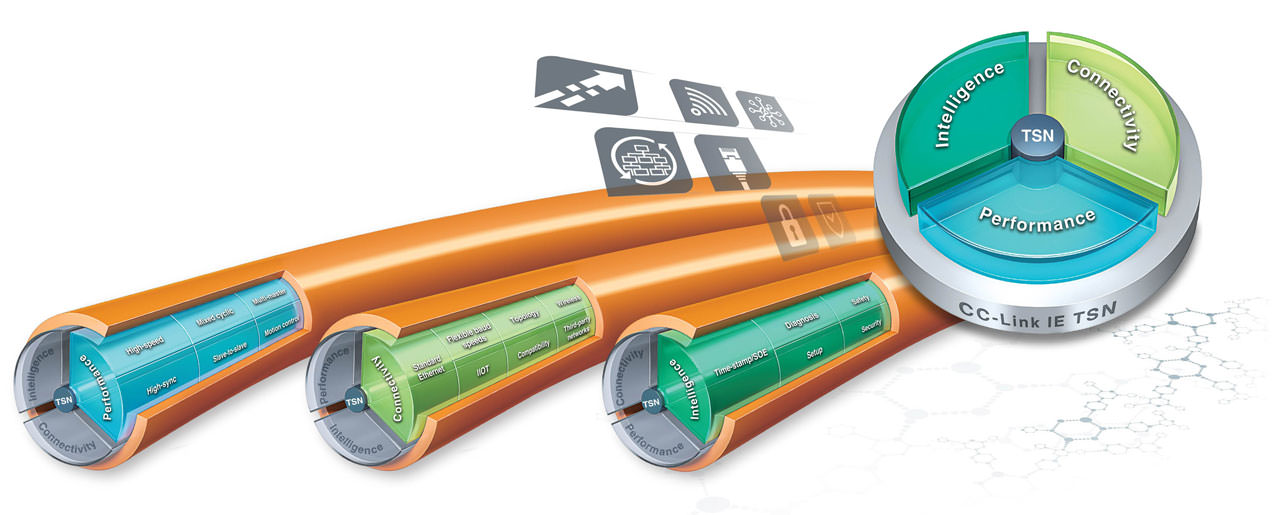

Looking at the impact of Time Sensitive Networking, two key points clearly come out. First, industries should consider what open network technologies are available to help them migrate current industrial Ethernet systems to TSN compatibility. Second, any assessment needs to combine TSN and gigabit Ethernet.

The implementation of a smart factory concept is designed to deliver ever-increasing efficiency and productivity. By providing a continuous stream of data flowing across an entire enterprise and beyond, it is possible to monitor and manage manufacturing processes in real-time. Time-Sensitive Networking (TSN) technology is bringing what was on the horizon for Smart Manufacturing closer by offering an increasingly holistic approach to industrial communications today.

Connectivity is a crucial requirement in the digital transformation that is currently being experienced in the industrial landscape, and its role will continue to become increasingly prominent. Standard industrial Ethernet has served manufacturing industries well for a long time, evolving over the years to address new challenges and requirements in industrial communications. However, some of its features are becoming increasingly obsolete, hindering businesses in adopting Industry 4.0.

Only a new technology, built around the needs of Smart Manufacturing, the Industrial Internet of Things (IIoT) and Big Data, can successfully address this issue. TSN, as defined by IEEE 802.1, provides a migration path to the future for current industrial Ethernet.

TSN as defined by IEEE 802.1 provides a migration path to the future for current Industrial Ethernet implementations.

What TSN can do for business?

Fundamentally, the creation of a responsive and transparent cyber-physical enterprise requires high-level systems to monitor, control and make decentralised autonomous decisions on all process operations. The most elegant way to achieve this is by using one single industrial network to provide the necessary convergence of information technology (IT) and operational technology (OT). In practice, only a few companies have this luxury. Typically, any given plant will have many different types of networks, as installations take place over time and according to different needs. TSN can address this issue by offering the possibility to unify multiple different industrial Ethernet protocols on the same network infrastructure.

These capabilities are enabled by the set of IEEE 802.1 standards that define TSN. Key amongst them are 802.1AS and Qbv. These define the synchronisation of devices on a network and control the prioritisation of traffic respectively. TSN ensures that vital process data is handled in a reliable and deterministic manner, while allowing lower priority traffic to co-exist on the same network. Hence, not only does TSN offer productivity benefits, but it also lowers cost of ownership associated with the network infrastructure.

The removal of any physical separation between critical and non-critical data sharing, simplifies network planning as well as reducing capital expenditure (CAPEX) and operating expenses (OPEX) associated with cabling and network administration.

Attention has been focused on the fact that TSN allows “standard” Ethernet to be deterministic. While this is true, TSN only addresses the data link layer of Ethernet. It does not consider higher level functions addressed by industrial Ethernet protocols, such as safety and motion control. Users looking for a migration path to future communications need to consider how TSN can be combined with these needs to ensure high performance and functionality.

Moreover, as a series of open IEEE technical standards that device makers can currently pick and mix, TSN ensures openness and future interconnectivity among technologies adhering to the same IEEE 802.1 sub-standards. The IEC/IEEE 60802 working group is currently building on this by creating a set of profiles for using TSN in automation to ensure standardisation.

Revolutionising smart manufacturing

These opportunities have the potential to contribute to improving manufacturing processes and increased competitiveness for businesses that adopt TSN. In the long term, they will transform global manufacturing. Major players in the factory automation business have already introduced a range of products that support TSN, so the concept isn’t a theoretical tomorrow’s world, but very much a solid step in the evolution of industrial networking. The level of connectivity offered by TSN will help to connect different ‘islands of automation’ within a production plant into one independent and self-coordinated ‘living system’ responsive to many variables including both fluctuating inputs and scheduled events.

Cyber-physical systems that TSN can support are not confined to automation but can be extended to asset management and predictive maintenance. When combined with OPC UA, TSN provides an efficient and reliable network for the transfer of high-quality, real-world data on the performance of physical machines and their virtual counterparts. As a result, it is possible to create highly accurate and responsive real-time digital twins.

Consider adopting TSN technology?

As a key enabler for Industry 4.0, TSN will likely become a must for industrial communications. Development teams from different disciplines from IT and engineering, to manufacturing and logistics, should start researching and planning the implementation this technology into their industrial communication networks. Looking at TSN is a chance to assess in-house systems and look for a migration path to address future needs. A parallel emerging trend is the growing need for increased bandwidth to handle the “explosion” of data that Industry 4.0 is generating.