TechnologyMarch 23, 2025

Time-Sensitive Networking system-level solutions

TSN backers continue to emphasize the inherent strengths of TSN networking technology. But now, new silicon solutions are set to enable step-by-step integration of TSN capabilities into a wide range of automation devices, potentially alleviating one of the greatest obstacles to greater adoption.

For this special report on TSN in factory automation, IEB reached out to industry experts to get their perspective on the technologies that are impacting TSN in smart manufacturing operations.

A key advantage of Time-Sensitive Networking is how it leverages innovative networking technology, combining traffic scheduling, prioritization and shaping in high performance manufacturing systems while also enabling the coexistence of disparate traffic types and protocols on the network.

But now in addition to the technology benefits of TSN itself, new silicon (Ethernet chipsets) are offering communication interfaces with multi-protocol support for a variety of protocols could alleviate one of the greatest obstacles to more widespread adoption.

System-level TSN solutions

New silicon enabling step-by-step integration of TSN capabilities in all automation devices

Gunnar Lessmann, Master Specialist Profinet and TSN, PLCnext Technology, Phoenix Contact GmbH & Co. KG said that one important prerequisite for TSN in factory automation is the integration of required capabilities and standards in all automation devices and network switches without additional cost.

“More and more silicon vendors integrate TSN capable interfaces in new generations of their silicon, while these are the same or less costly, than the version before. This leads to a step-by-step integration of TSN capabilities in all automation devices,” Lessmann said.

Lessmann said that one other important activity is the integration of relevant TSN features like time-synchronization according to IEEE 802.1AS and high precise frame transmission in Linux mainline kernels and tools. Both aspects will lead to decreased device and development cost of TSN devices combined with more performance. This integration in end devices is a must, to utilize new solutions like virtual PLC. Without TSN capable interfaces in hardware machines, such solutions will not be possible.

Furthermore, ongoing standardization activities like PROFINET, OPC UA FX, or IEEE/IEC 60802/61802 are gaining momentum and will find their way in the market.

“With that in mind, it is expected that all customers and applications which benefit from a converged network instead of separate networks will adopt the technology,” Lessmann said. “One example is the communication in large windfarms, where time synchronization and large data transfer is required in one network. In applications like these, it is not reasonable to use separate networks.”

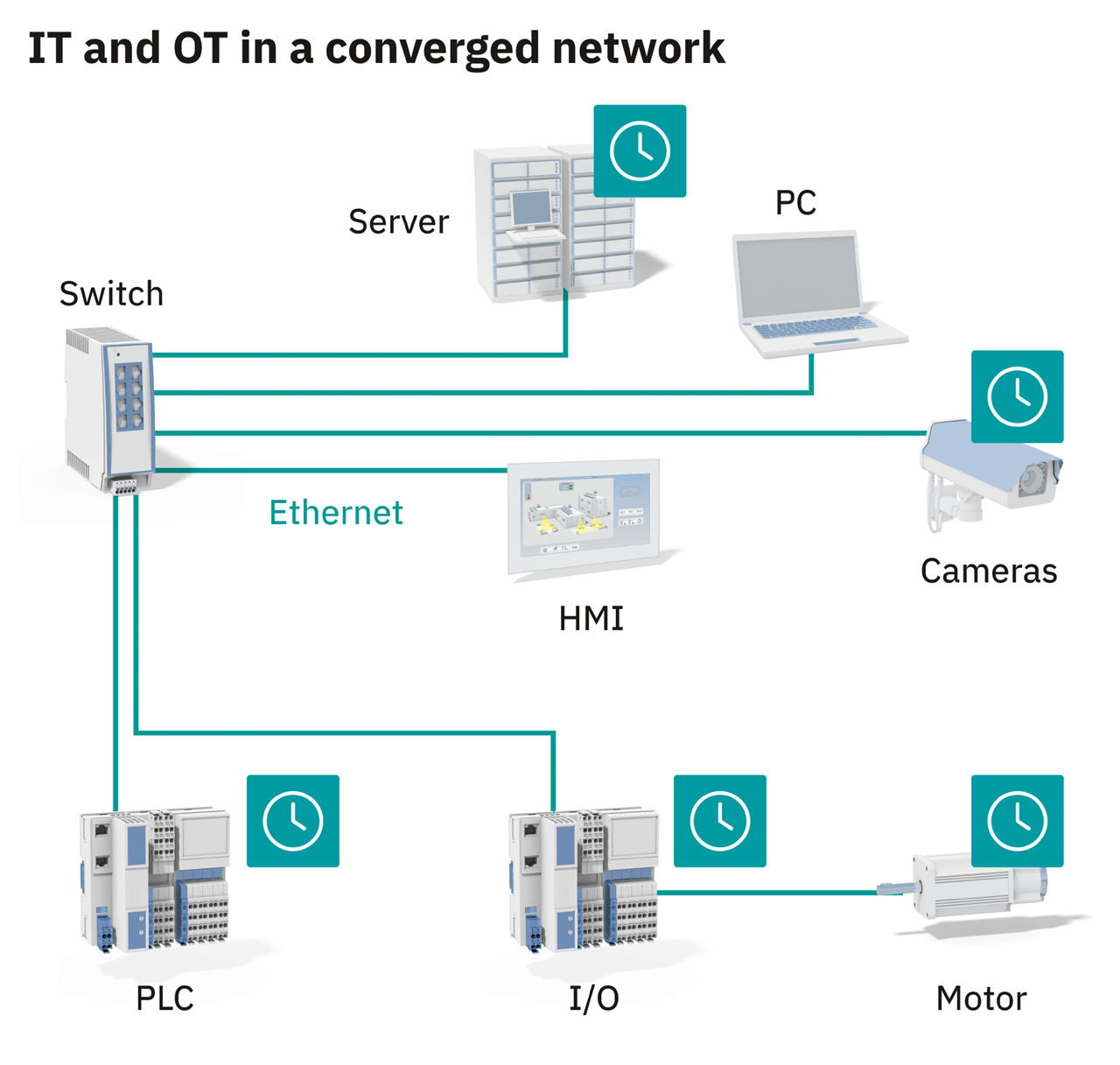

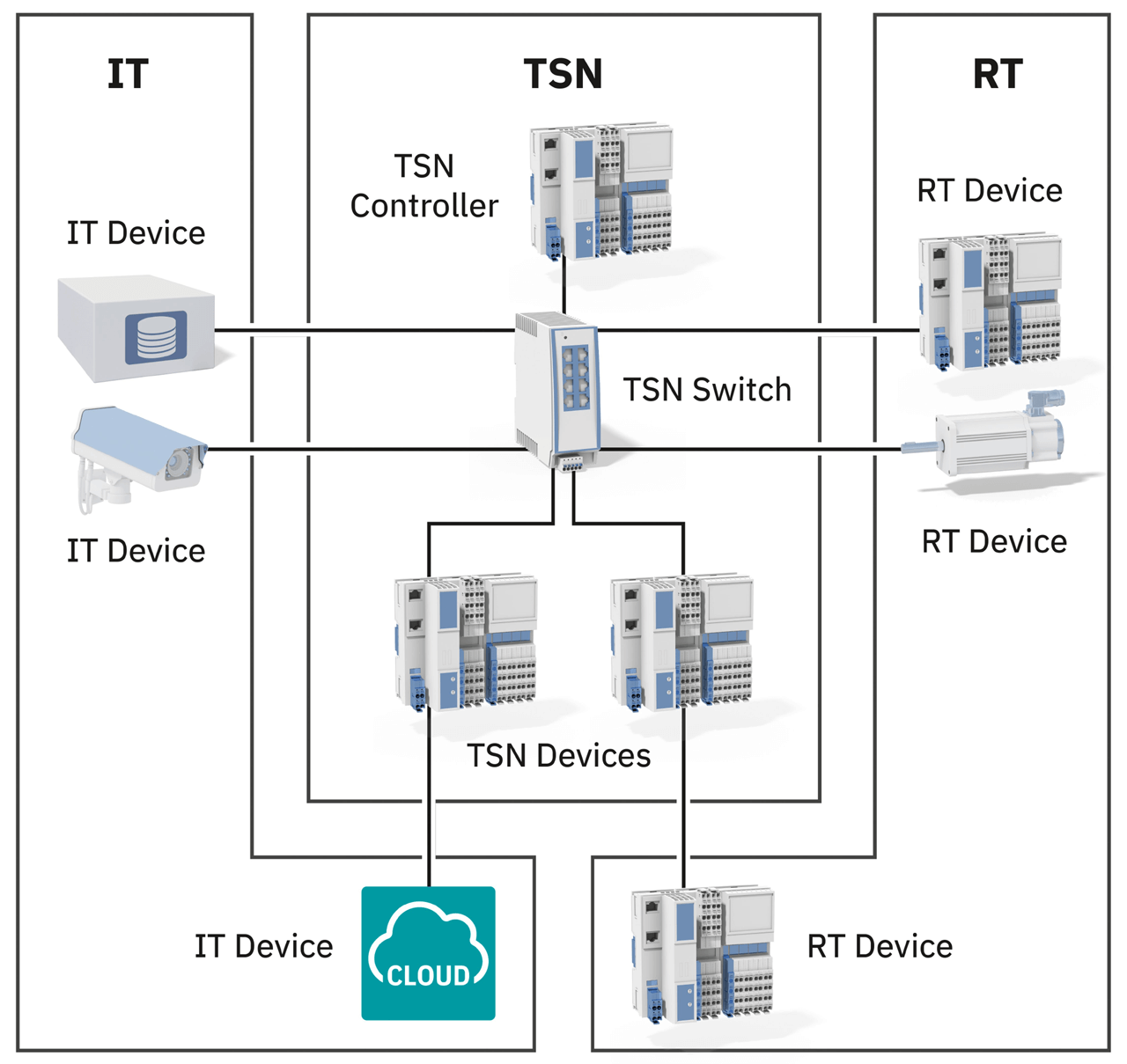

Figures 1 and 2 show the adoption of separated networks towards one converged TSN network.

Figure 1: One converged TSN network integrating all automation devices and disciplines.

Lessmann said that there are some challenges, which need to be solved to enable such a network. The communication standards like PROFINET or

OPC UA (FX) together with the base IEEE/IEC 60802 shall cover the required functionality and have the needed maturity. Furthermore, interoperability and conformance tests must cover these standards as well. This guarantees the problem-free operation in all end customer cases.

Specific technology benefits

Lessmann said that in converged networks, as shown above, TSN is offering some technologic benefits. In particular:

- High precise time synchronization with accuracy better then 1µs even in larger networks

- Scalable bandwidth from 10Mbit/s to 10Gbit/s

- Transportation of real time-critical and best effort Ethernet traffic without mutual influence and predictable latency

- Bump less media redundancy for real-time data, if required by the application

- Seamless Integration of existing “Brownfield” devices without breaking the system usability

These benefits are not fulfilled with more “Fieldbus” -like specialized systems. In long-term the benefit of a unified converged network will be adapted by all applications starting with those, where the effort vs. benefit is positive.

TSN is applicable for all types of applications and customers. Examples of applications include:

- Manufacturer of a series of machines where the network in the machine itself is implemented with only one system replacing multiple specialized networks and devices.

- Integration and operation of multiple machines in production cells and plants with real-time critical controller to controller and controller to IT communication

- Integration of monitoring devices like IP-cameras in the same network, where the image recognition is running on a powerful platform.

- Machine learning applications based on synchronized cameras or vibration sensors.

- Virtualized PLCs running on COTS (custom off the shelf) Hardware- and Software. This is an enabling use-case for new possibilities like combining

PLC and machine learning on the same machine with the same network. Figure 2 shows one example.

Figure 2: Example for a converged network with IT, Realtime Critical and TSN components.

Anticipated TSN impact

“With the capabilities of TSN standards and the integration in all automation components we expect more and more replacement of specialized and separated systems to be integrated,” Lessmann said. “In combination with new possibilities like virtual PLC, machine learning and AI, TSN is will be the enabling technology without alternatives. Due to seamless brownfield integration concepts this transition can be smooth according to the most benefits of the respective specific application. Even though this transition will take time. The next 1-3 years will tell.”

“Ethernet with Time Sensitive Networking is leveraging the latest in technology including Gigabit Ethernet speeds combined with traffic scheduling, prioritization and shaping. These features enable the highest level of performance while also enabling the coexistence of disparate traffic types and protocols.” — Thomas Burke, Strategic Global Advisor at CC Link Partner Association.

Ethernet with TSN

Gigabit speeds combined with traffic scheduling, prioritization and shaping

According to Thomas Burke, Strategic Global Advisor at CC Link Partner Association, Time Sensitive Networking is continuing to evolve for use in factory automation applications.

CC-Link IE TSN has been available since 2018, and dozens of device manufacturers are delivering compatible products.

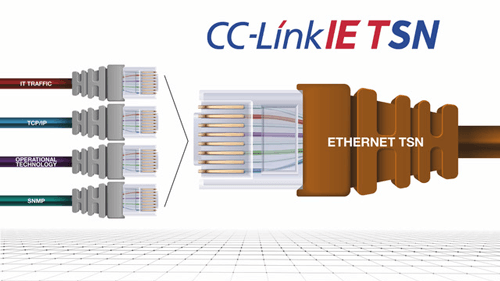

“Ethernet with Time Sensitive Networking is leveraging the latest in technology including Gigabit Ethernet speeds combined with traffic scheduling, prioritization and shaping,” Burke told the Industrial Ethernet Book recently. “These features enable the highest level of performance while also enabling the coexistence of disparate traffic types and protocols.”

Burke said that the support of these latest features requires an upgrade to new silicon (new Ethernet Chipsets). This creates a common challenge for device designers and there are several companies that offer communication interfaces with multi-protocol support.

“In the case of Ethernet with TSN-based protocols, one leading protocol, CC-Link IE TSN has been available since 2018, and dozens of device manufacturers are delivering compatible products. Major protocol vendors including Hilscher, HMS, Renesas offer new chipsets with support for a variety of protocols. This alleviates the greatest obstacle to adoption,” Burke said.

Technology benefits

One of the key technology benefits of TSN is that it delivers the ability to schedule communications at the microsecond level.

This scheduling, combined with prioritization of messages and the ability to shape large traffic, and preempt messages, enable guaranteed performance for critical traffic (motion control for example), while coexisting with video, data acquisition or maintenance communications. The ability to combine various communications on a common and open network is not available through any other solution.

Applications and impact

Burke said that applications that benefit from advanced motion control, the coordination of many axes, or the coordination of drives along a common machine for printing or lamination are common applications including printing machines and battery winding machines. While these machines require a great deal of coordination, other machines with many, even non-coordinated axis, can benefit from the control of many devices from a single, much more cost-effective controller.

Burke added that he expects TSN technology will continue to have on smart manufacturing in the next several years.

“While CC-Link IE TSN is currently the dominant solution for Ethernet with TSN communications, a number of other protocol solutions are soon to enter the market and will be supported by System on Chip (SoC) communication vendors,” Burke said. “There is no alternative to this technology trend. Ethernet with TSN is the next logical step for open, standards based industrial communications.”

“Time-Sensitive Networking is evolving to enhance real-time communication and network convergence in factory automation. It supports applications like robotics and advanced motion control with deterministic communication and low latency, autonomous operation using vision systems and AI with high bandwidth and data streaming, and connectivity for legacy components,” Georg Stöger, Senior Principal Technology Specialist at TTTech.

Impact on factory automation

Enhanced real-time communication and network convergence

“Time-Sensitive Networking (TSN) is evolving to enhance real-time communication and network convergence in factory automation. It supports applications like robotics and advanced motion control with deterministic communication and low latency, autonomous operation using vision systems and AI with high bandwidth and data streaming, and connectivity for legacy components as well as the most up-to-date TSN enabled devices,” Georg Stöger, Senior Principal Technology Specialist at TTTech said.

Stöger said that adoption on a larger scale progresses slowly, because compatible devices and infrastructure are not widely available. For this reason, customers typically do not proactively switch to TSN technology to benefit from its known advantages until the existing legacy technologies do not meet new requirements such as higher bandwidth.

In addition, he added that interoperability between different vendors’ equipment might need to be improved. Despite TSN’s adherence to IEEE standards, different device capabilities exist beyond those defined as mandatory by the applicable TSN profile(s). Lastly, the evolving cybersecurity landscape necessitates robust security measures to protect converged IT-OT networks, adding another layer of complexity to any system upgrade, including the move towards TSN. Despite these challenges, the long-term benefits of TSN make it a promising technology for smart manufacturing.

Factory automation applications

“While TSN is sometimes still considered mainly as fieldbus, TSN in fact offers key benefits for factory automation applications: It provides deterministic real-time communication over standard Ethernet, ensuring low latency and high reliability for multiple industrial traffic classes simultaneously,” Stöger said. “This is critical for precise control and synchronization in automated processes. The key principles to achieve this are time synchronization and traffic scheduling, allowing for the convergence of IT and OT networks and applications on a single TSN network backbone infrastructure.”

Identifying specific competing solutions to compare TSN with is tricky here, because TSN’s unique advantage lies in the combination of the aforementioned determinism and its adherence to IEEE standards, which ensures compatibility to legacy devices and at the same time makes solutions more future-proof.

No other set of IEEE standards offers these capabilities for support of OT networking, and unlike proprietary protocols which may offer similar benefits on a factory network, TSN’s standardized approach allows for broader adoption and compatibility across different vendors and devices.

Meeting high bandwidth requirements

“A notable trend is to consider using TSN not just for its determinism, but to address high bandwidth requirements, arising from innovative applications such as vision systems and data analytics,” Stöger said.

He added that, of course, OT applications that require deterministic network communication and applications which need a lot of network bandwidth are not mutually exclusive in complex systems such as a factory or large machine network. TSN’s standards-based independence from any specific restriction with respect to physical layer (optical, electrical…) and data rate constraints (10/100 Mbit/s, 1 Gbit/s, 5 Gbit/s…) is ideally suited to provide determinism for some traffic classes while supporting very high network bandwidth in the 10 Gbit/s range for other traffic classes.

Although 10 Gbit/s data rates are not currently mandated by any TSN profile, implementations are available and customer interest for TSN network data rates beyond the mandatory 1 Gbit/s exists.

Looking ahead

“The current key trends we observe include increasing autonomy in automation and a strong focus on cybersecurity,” Stöger said.

Autonomy does not only affect “wired” assets such as stationary robots and machines, but also mobile assets (AGVs) which need to use wireless data communication in the automation system.

Wireless data communication that nevertheless needs to provide comparable capabilities to TSN goes beyond the scope of IEEE TSN and the industrial TSN profile and needs “wireless TSN”, where a combination of TSN networks and 5G networks is used to achieve the required network QoS, synchronization, robustness, and determinism.

“The cybersecurity aspect is very challenging because it must address the increasing multitude and dynamics of network data flows introduced by AI and on-demand network requirements such as ‘plug and produce’ but also provide the transparency and diagnostic capabilities needed to ensure that applicable regulatory frameworks can be met,” Stöger added.

“Consequently, we expect that in the coming years TSN will contribute to smart manufacturing networks mainly in the areas of reliability and robustness. But as stated earlier, we also see massive increases in bandwidth demands for some applications, driven for example by AI applications which need to process a large amount of near-real-time vision data for autonomous functions in smart manufacturing.”