TechnologyMay 18, 2022

2022 EtherCAT Solutions Update: Special Report

Special report provides an update on EtherCAT automation and control technology, and the viewpoint of industry experts in EtherCAT technology and applications. A series of technical articles and application case studies provide an update of the state-of-the-art in EtherCAT automation networking.

This “2022 EtherCAT Solutions Update” special report provides the perspective of industry experts and their insights into the development of EtherCAT technologies and the megatrends shaping and enabling development of industrial automation and control networks. For the IEB Special Report on EtherCAT, we reached out to Dr. Guido Beckmann, Senior Management Control System Architecture & International Key Accounts at Beckhoff Automation and Martin Rostan, Executive Director at the EtherCAT Technology Group to provide readers an update on this key Industrial Ethernet technology.

This “2022 EtherCAT Solutions Update” special report provides the perspective of industry experts and their insights into the development of EtherCAT technologies and the megatrends shaping and enabling development of industrial automation and control networks. For the IEB Special Report on EtherCAT, we reached out to Dr. Guido Beckmann, Senior Management Control System Architecture & International Key Accounts at Beckhoff Automation and Martin Rostan, Executive Director at the EtherCAT Technology Group to provide readers an update on this key Industrial Ethernet technology.

View the Ebook, or view the individual articles by clicking below.

EtherCAT technology and applications update

Ethernet for Control Automation Technology (EtherCAT) is a real-time Industrial Ethernet technology. An update from industry experts reveals an industrial protocol with a continuing technology focus on its roots: short cycle times (≤100 µs), low jitter for accurate synchronization (≤1 µs) and low hardware costs.

Learn more

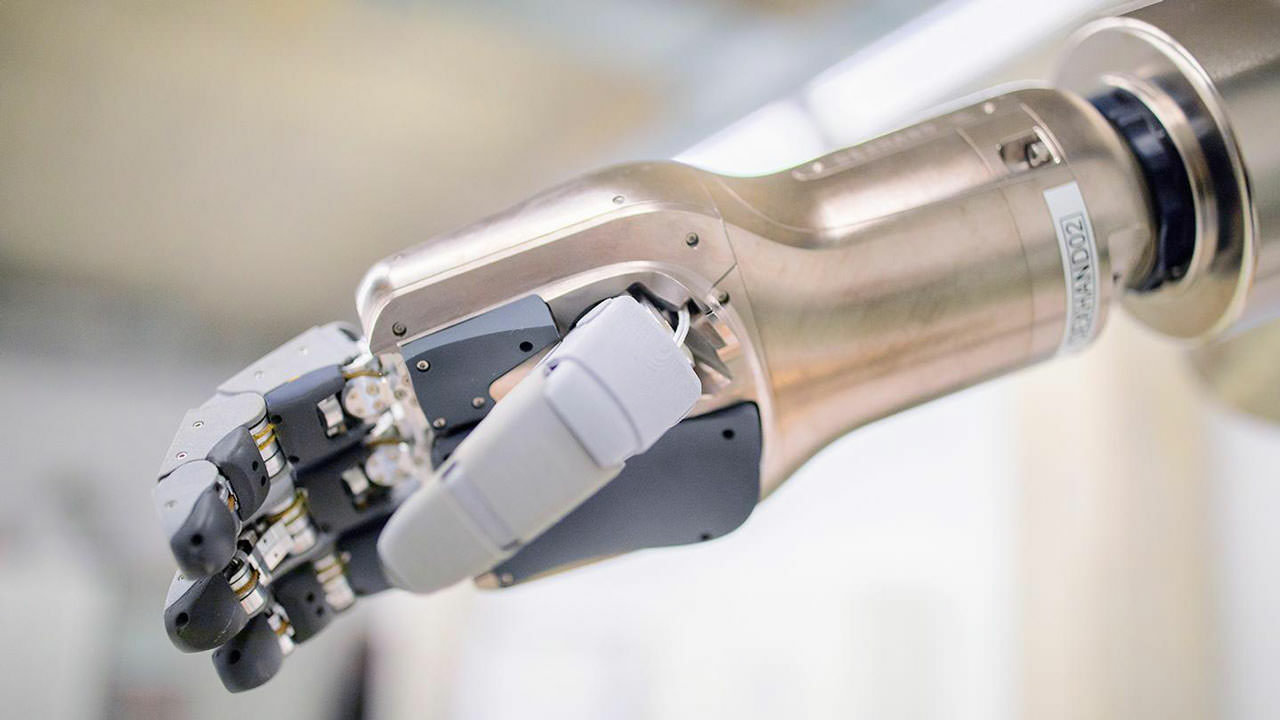

EtherCAT in Space Robotics

The space industry is increasingly taking the approach that what has been successfully proved on Earth can also work in space. This is how the suppliers of space robotics came to EtherCAT, adapting technology for motion control applications on earth is well-suited for corresponding applications in space.

Learn more

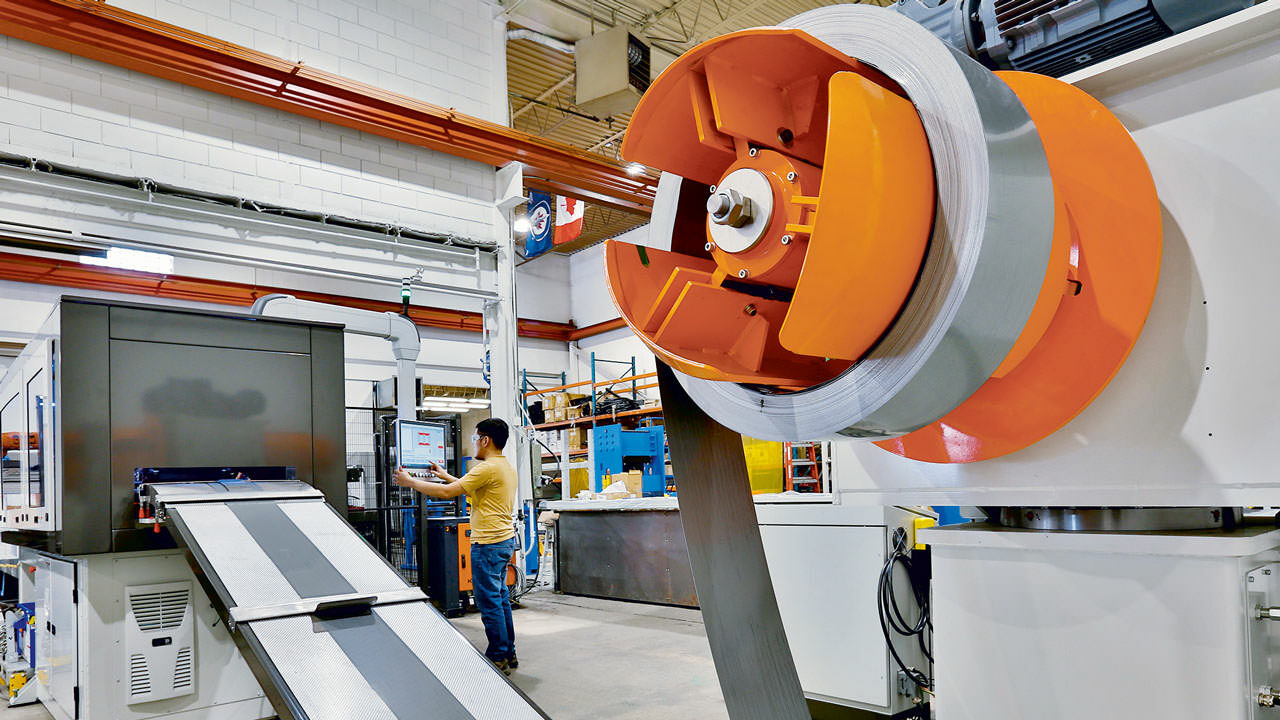

PC-based control and EtherCAT boost machine throughput 55%

A fully integrated EtherCAT control platform has resulted in an efficient and precise machine for manufacturing transformer cores. A switch from a legacy PLC to a fully integrated Beckhoff control platform helped increase production rates by more than half, while also improving the level of precision in manufacturing.

Learn more

TwinCAT and CAM connections increase productivity of fiber laser machining centers

Plasma-Tech Systems, manufactures custom laser equipment and specialized machines. With the PTL 4001, a fully automatic processing center using a fiber laser was developed and automated with PC-based control and advanced laser cutting NC technology from Beckhoff.

Learn more

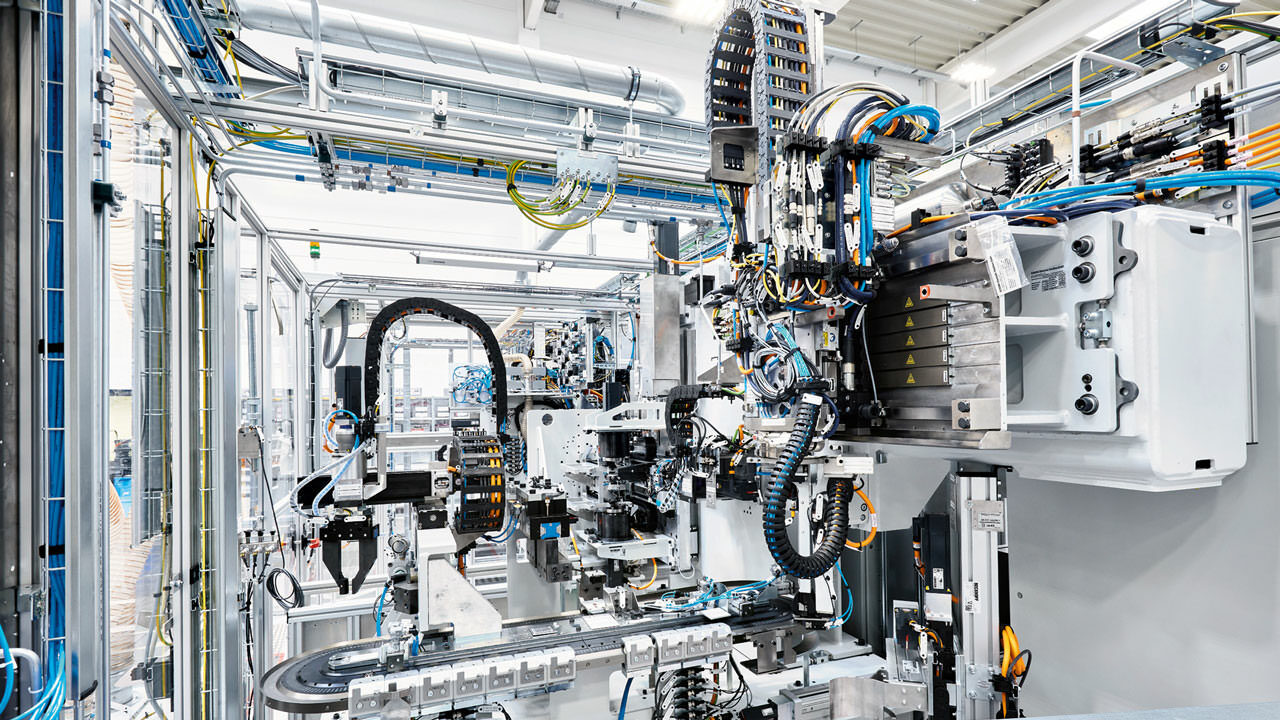

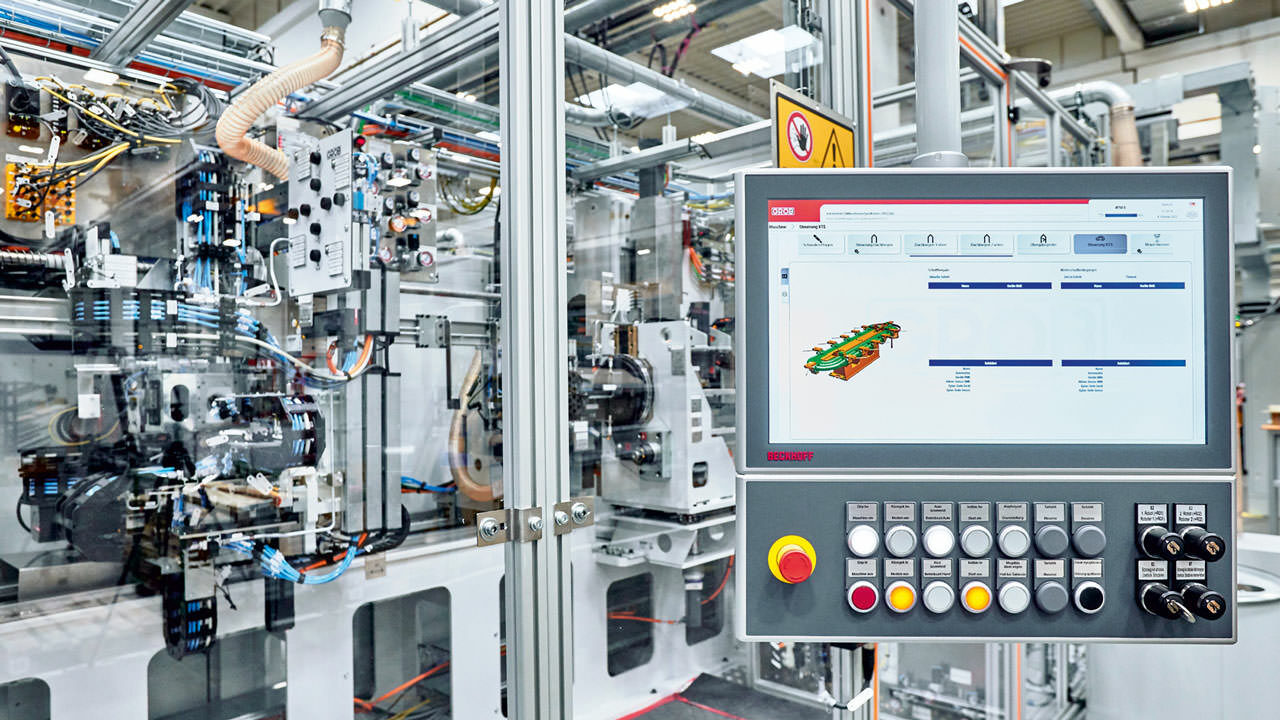

Flexible EtherCAT control technology with fast cycle times increases efficiency

A sophisticated production machine for hairpins, from which the stator winding rims of electric motors are formed, illustrates the advantages of this optimally scalable automation solution. It leverages TwinCAT 3 on a Beckhoff C603x ultra-compact Industrial PC as the central control platform and the XTS transport system.

Learn more

EtherCAT Conformance Test Tool Version 2.3 released

Conformance to the protocol standard is the basis for the problem-free interaction of devices from different manufacturers in the same network, also called in short interoperability. Version 2.3 carries on all functionalities and tests of the first version and underlines the stability of EtherCAT technology itself.

Learn more