TechnologyMarch 21, 2022

Time-Sensitive Networking 2022 Technology Update

Industry experts provide their perspective on the development of Time Sensitive Networking (TSN). Learn how global manufacturers can reap the benefits of Industry 4.0, leverage new levels of deterministic performance and capitalize on new connectivity options in pursuit of true IT-OT convergence.

TIME SENSITIVE NETWORKING TECHNOLOGY offers the potential of an unprecedented level of standardized, deterministic performance for factory automation, along with the business benefits of converging multiple network types that separate the OT-IT worlds.

For our 2022 TSN Technology Update, IEB reached out to industry experts to get their insights into the development of TSN and their perspectives on the megatrends and applications shaping and enabling development of this important technology.

Key technologies to watch include the final emergence of IEC/IEEE 60802 TSN which promises to provide coexistence, higher network utilization and improved configuration tools. OPC UA FX and Wireless TSN have the potential to make factories both more efficient and more transparent.

But experts also note that more products and TSN solutions are on the way. We’re just starting to understand how TSN will make an impact on smart manufacturing by delivering higher levels of determinism and performance.

TSN Toolbox

Emphasis on Quality of Service

When asked what technology will be enabling development of Time-Sensitive Networking application solutions and the challenges to more large scale adoption in 2022 and beyond, Günter Steindl, Enterprise Architect at Siemens Digital Industries, said the key is tools for the creation of secured, converged networks offering advanced industrial communications and connectivity.

“People should be aware that the Time Sensitive Networking project at the IEEE 802.1 working group had the goal to provide more means for Ethernet quality of service. Thus, TSN is just a toolbox offering more control about the timely behavior of Ethernet,” Steindl told IEB recently.

“This toolbox is used by the IEC/IEEE 60802 to provide a secured converged networks to industrial automation. A secured converged networks is the basis for communication and connectivity required by Industry 4.0.”

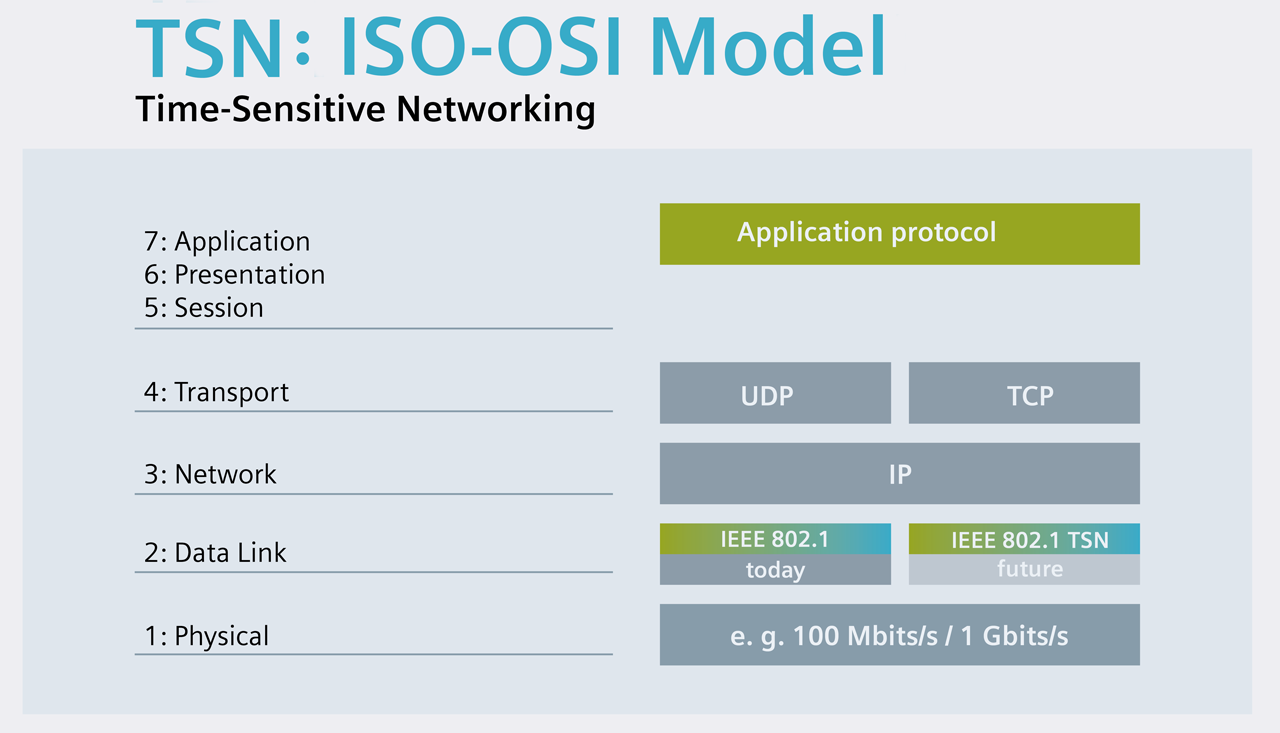

Time Sensitive Networking ISO-OSI model.

He added that PROFINET and OPC UA FX are currently being adapted to work with IEC/IEEE 60802 secured converged networks. Hardware and software for bridges and end stations are more and more adapted to support the features required IEC/IEEE 60802 secured converged networks.

Technology highlights

Steindl stated that the TSN toolbox extends the previous existing mechanisms to control quality of service for Ethernet networks. But what are tools without knowledge how to handle them?

That’s the reason why the plug & produce support provided by the IEC/IEEE 60802 is the key for the usability. Centralized network controllers configure the stations setting up the secured converged network. Customers are only required to state their quality-of-service requirements for the communication relations.

He added that the industrial automation market will adapt the features provided by the TSN toolbox. IEC/IEEE 60802 secured converged networks will provide, together with PROFINET and OPC UA FX, the plug & produce feature required by Industry 4.0.

Factory automation, Process automation or Motion control, all verticals could be handled by such kind of networks and stations.

IEC/IEEE 60802 specifies procedures for separating the communication and connectivity configuration from the PROFINET and OPC UA FX configuration. This separation is the prerequisite for an IT/OT convergence.

He stated that there are many specific application benefits that will enable adoption of TSN, versus what is possible with typical applications today.

“IEC/IEEE 60802 secured converged networks together with plug & produce are the key,” Steindl said. In addition, using the TSN toolbox will push the interoperability between wireline and wireless networks. Other verticals, for example professional audio/video, are assumed to share the same secured converged networks.”

Impact of TSN technology & timeline

“Plug & produce and interoperability between wireline and wireless networks are a precondition for smart manufacturing,” he added.

He also said that IEC/IEEE 60802 secured converged networks are addressing plug & produce. 3GPP / 5G and IEEE802.11 are addressing interoperability between wireline and wireless networks. IEC/IEEE 60802 secured converged networks specification will be available in 2023, 5G and IEEE802.11 specification at a later date.

TSN Technologies

Support by upper layer industrial protocols

According to Moxa Europe, the upper layer industrial control protocols will need to adopt TSN and truly integrate TSN into the overall system. This will enable the development of TSN technologies, and companies will develop and launch more and more commercial TSN-related products and solutions.

“In the coming 1-2 years, we believe that the situation with supply chain interruption and the shortage of materials and manpower due to the COVID-19 pandemic will remain the biggest challenges to more large scale adoption of TSN as companies will be more reluctant and conservative to do new site and new technology investment,” they said.

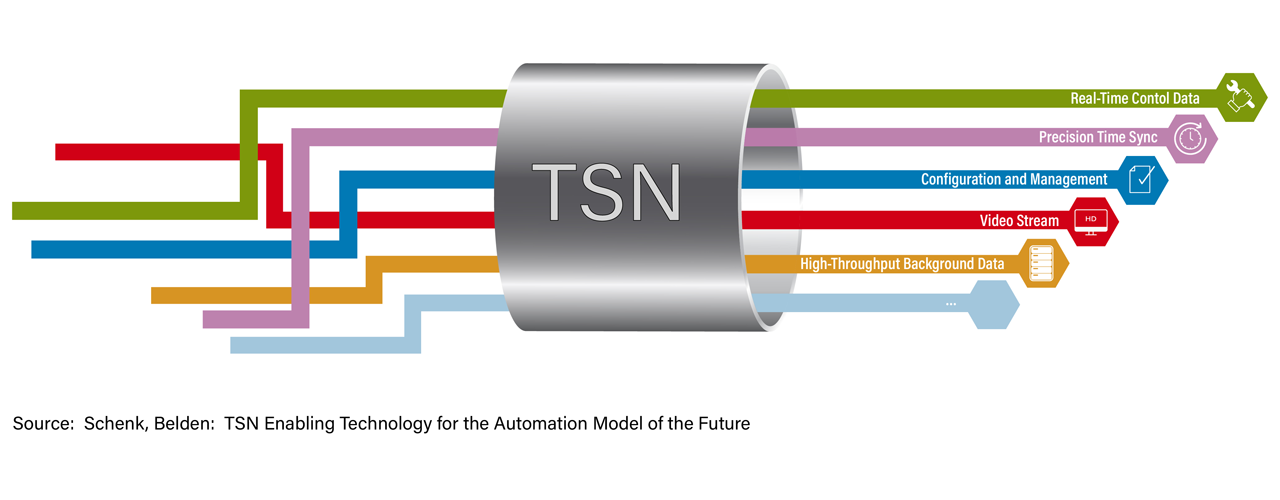

Moxa stated that the current trends of automation and data exchange in manufacturing, also referred to as “Industry 4.0” or the “Industrial Internet of Things” (IIoT), are based upon digitization. By converting analog signals, sounds, images, texts, and other information into a computer-readable format, digitization has been transforming industries for decades. For manufacturers to make sense of all these bits of information, the data must be transported from numerous sensors and equipment on the factory floor and processed for humans or other machines to make informed decisions in real-time.

In the current Purdue model, industrial automation forms a pyramid where isolated purpose-built protocols automate specific tasks within distinct layers. However, this model gives rise to a number of infrastructure challenges for modern industrial networks. The protocols are essentially speaking different “languages”, which often results in difficulties when real-time communication is required.

With the advent of Time-sensitive networking (TSN), standard Ethernet networks are now able to provide deterministic services and integrate the “islands of automation” that were previously isolated by the numerous purpose-built protocols.

TSN is a collection of standards that enables deterministic messaging over standard Ethernet networks. As defined by the Institute of Electrical and Electronics Engineers (IEEE), TSN involves a form of network traffic management to ensure non-negotiable time frames for end-to-end transmission latencies. Consequently, all TSN devices must synchronize their clocks with each other and use a common time reference to support real-time communications for industrial control applications.

In other words, TSN provides a standard and unified infrastructure for delivering data to the right place at the right time.

Applications and markets

Moxa foresees that TSN can and will be used in various applications. As mentioned above, almost all industrial automation applications that are adapting digital transformation can benefit from TSN adoption as TSN provides a standard and unified infrastructure for large-scale converged network.

According to Moxa, the current typical applications are limited to network silos. TSN provides reliability, scalability, flexibility, and determinism in a converged automation network.

Smart manufacturing adopting TSN will achieve higher production efficiency by reducing the total cost of ownership (TCO) and by increasing visibility and real-time data aggregation for production optimization. “We already see pilot and small-scale landing projects all over the world, and we expect that TSN will become more and more popular in the coming 1-3 years,” they reported.

OPC UA & TSN

Enabling smart manufacturing solutions

According to Philip Marshall, CEO, Hilscher North America: “At the start of the TSN standardization process, there were expectations that TSN would replace existing industrial Ethernet standards. Today, we’re looking at the different field layers to evaluate controller-to-controller networking over gigabit Ethernet via TSN. In addition, 5G Standard Release 16 will offer more low-latency capabilities and provide wireless TSN routing on the factory floor. However, this development will take longer to adopt.”

“Meanwhile, when it comes to communication from the shop floor to the cloud and edge layer, OPC UA sets the standard and may become an enabling technology when combined with TSN. However, configuration complexities associated with Linux networks make merging with field devices a challenge,” Marshall said.

Time Sensitive Networking ISO-OSI model.

Marshall said that TSN extends IEEE Ethernet Standards to cover the real-time Ethernet requirements of industrial networks. It originated from a merge within IEEE to form the TSN Task Group. At first, TSN standards were based on audio and video bridging standards, and adopted the following concepts:

- “Talkers” and “Listeners” were introduced to the standard Ethernet model and defined streams between the mentioned components.

- One Talker could communicate with several listeners in one data stream.

Today, TSN includes more than nine standards and describes how the existing standards need to be extended to meet certain behaviors in the communication channel. TSN enables data transfer from one device to many with defined requirements like:

- Low latency.

- Low jitter.

- Cycle time.

- Redundancy.

- Number of streams — coupled to the number of Talkers and Listeners.

These requirements resemble the current goals of Ethernet-based fieldbus standards, but are now defined in a set of IEEE sub-standards. The most important are:

Timing and synchronization for time-sensitive applications according to IEEE 802.1AS 2020

Features include: synchronized timing between all nodes and the master clock; ability to correlate network events and actual time (sequence of events); definitions of multiple time domains; redundant synchronization; faster “Grand Master” changeover; and reduce best master clock algorithm (BMCA) convergence time.

Enhancements for scheduled traffic according to IEEE 802.1Q-2018 (formerly IEEE 802.1Qbv)

This includes the ability to: extend transmission behavior of Ethernet components; Time sharing method; reserve bandwidth for desired traffic classes; network cycle-based; and required IEEE 802.1AS standard.

Frame preemption according to IEEE 802.1Q-2018 (formerly IEEE 802.1Qbu):

Needs Interspersing Express Traffic (IET) according to IEEE 802.3-2018 (formerly IEEE 802.3br)

Stream Reservation Protocol (SRP) according to IEEE 802.1Qc

This configures all standards and mechanisms and consists of these major models:

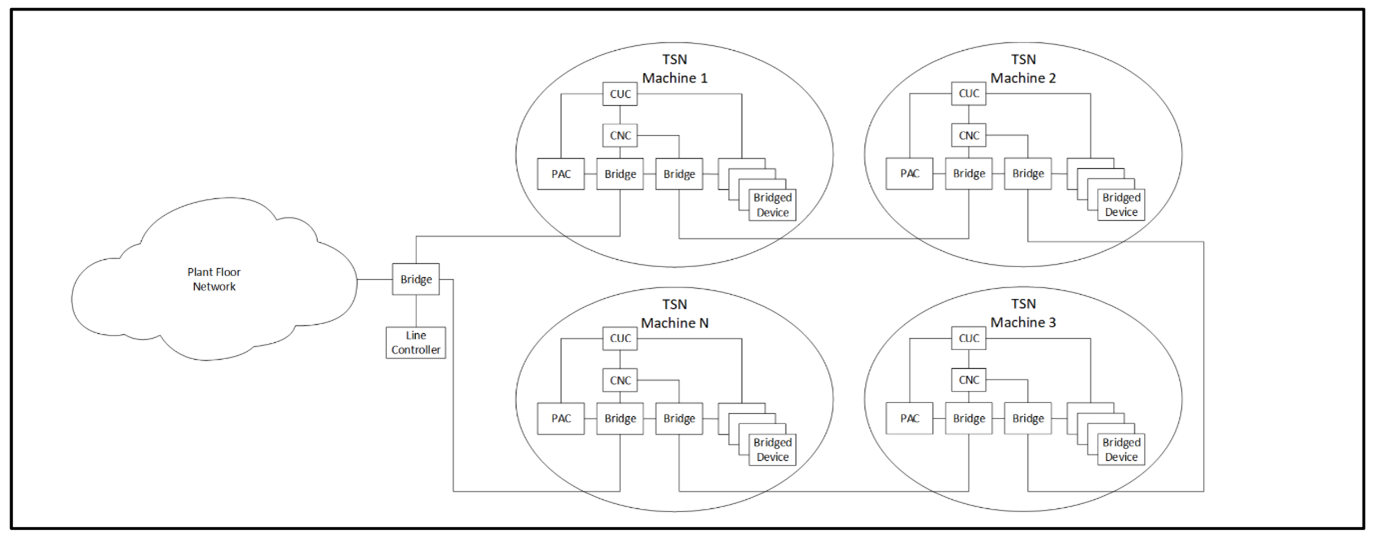

- Centralized configuration: similar to the Software Defined Network

- Centralized user configuration (CUC): which collects all requirements for the streams from the Talkers and Listeners and requests the establishment of the streams from the Centralized Network Configuration (CNC). The CNC receives the information required to establish streams between the Talkers and Listeners, then calculates the schedule and configuration to meet the given stream requirements; and

- Decentralized configuration: e.g., the automated stream configuration, although this standardization is not yet finished.

The challenge is that these standards cover any possible requirements of a real-time system. However, application requirements vary widely in terms of the standards actually required or quantity of required streams. For this reason, the IEEE TSN specs define only the transport mechanism itself.

Marshall said that it is a challenge to achieve common profile definitions and interoperability because implementation according to TSN standards alone is not enough. The core requirements for interoperability are:

- Selecting standards for defined applications (profile).

- Every mechanism needs a defined quantity structure and performance specification.

- Conformance test plans.

- Certification.

- Interoperable configuration of TSN networks.

He added that this makes up the core of IEC/IEEE 60802, with Hilscher contributing to a common set for interoperability.

Application areas

“TSN has applications in the automotive industry — for example, autonomous driving — and in manufacturing wherever complex machines from various suppliers need to interoperate in a real-time network,” Marshall said.

Some of the key benefits of TSN include the following: new possibilities to establish real-time communication between different components regardless of the manufacturer; and different real-time protocols can use the same cabling and connections, which is currently not possible. However, interoperable protocol configuration is a prerequisite. Additional use-cases will emerge along with combining wired and wireless real-time networks.

“TSN enables standardized, real-time and vendor-independent communication in an industrial network and allows you to use the same wire for various applications,” Marshall added. “An example is having video and audio streams reliably transmit in parallel to multiple RTE protocols over the same media.”

At the same time, TSN maintains the benefits of some fieldbuses — e.g., the ability to use multiple types of network topologies, such as ring, star or daisy chain. This feature frees up the network setup according to application needs.

In addition, TSN does not limit bandwidth, so high link speeds above 1 Gigabit per second are possible. This feature future-proofs the standard and enables real-time traffic to be transferred over the same wire. Possible applications in industrial automation include:

- Communication between machines from different vendors in real-time.

- Prerequisite: same protocol.

- Merging of the ERP and MES levels.

- Real-time data streaming to a local cloud entity.

- Machine builders can decide which data is accessible.

- Centralized control.

- Usage of TSN on all levels (field to MES).

- Removes the hierarchical structure of today’s automation networks.

- PLCs are combined into a central unit.

- Remote control of actuators and sensors.

- Enables flexible manufacturing due to scalable virtual functionalities (virtual PLC).

“The introduction of TSN will lead to consolidation in the industrial Ethernet protocol landscape,” Marshall said. “Some protocols, however, will not migrate to Gigabit Ethernet, and we don’t expect one protocol to dominate the market and replace all established industrial Ethernet standards used in 100 Megabit networks. Since TSN is mainly a layer-two standard, major protocols will adapt and integrate it in their specifications as an alternative — for example, PROFINET over TSN or CC-Link TSN and others.”

“We expect TSN to become the standard in controller interfaces based on Gigabit Ethernet to allow controller function clustering, enabling different machine controls within distributed systems and increasing effectiveness. Potentially, even different machine topologies can coexist under the label of smart manufacturing,” he added.

Marshall said that the industrial TSN profile specification IEC/IEEE 60802 is still in development and unreleased. The broad rollout of TSN will begin in 2023, pending discussions on security algorithms at the field-level, as well as industry trends to pre-process data in field devices.

Hilscher regards TSN as a key technology, and plans to significantly invest in hardware and software development for next-generation Gigabit Ethernet communication.

“Because of our efforts, we have already implemented 100 Megabit per second TSN standards for our netX 90 network controller for evaluation purposes. We continue to gain valuable experience that we will incorporate into future developments, enabling us to react quickly to the ongoing standardization process,” he concluded.

TSN technology outlook

Optimal network coexistence and prioritization

“Time Sensitive Networking (TSN) for EtherNet/IPTM will be made possible through the IEEE 802.1Q-2018 and amendments, IEEE 802.1CB, IEEE 802.1AS-2020, IEEE 802.1AB-2016 and IEC/IEEE 60802 standards, resulting in optimal network coexistence and prioritization,” Dr. Al Beydoun, President and Executive Director at ODVA, told IEB recently.

“A new Common Industrial Profile (CIPTM) Application Profile that will be released after IEC/IEEE 60802 is published will make IEC/IEEE 60802-enabled TSN an option for EtherNet/IP. End users will be able to natively implement the TSN application profile or leverage a gateway to allow for con-verged communication over a TSN network. Either approach will allow for fair network level access with other IEC/IEEE 60802-compliant devices. Existing EtherNet/IP devices can also work on TSN networks, although their Quality of Service on the wire may be degraded when com-pared to a non-TSN network,” he added.

Beydoun said that the development of Centralized Network Controllers and centralized configuration entities to properly configure the communications between TSN devices in a common manner will pose a significant hurdle.

Substantial development resources and additional cooperation above and beyond the current IEC/IEEE 60802 specification work will be required since this shared communications configuration for a converged ecosystem of industrial networks is a new concept.

Additionally, vendors must commit to developing a significant number of new devices across multiple product lines to offer end users a sufficient ecosystem to encourage adoption. Also, end users must commit to the added capital expenditure of introducing an entirely new network that is IEC/IEEE 60802 TSN compliant in order to reap the most possible network coexistence, traffic prioritization, and network utilization benefits. Finally, standards developers must continue to develop the IEC/IEEE 60802 standard to enable time sensitive transport between TSN segments and subnets.

IEC/IEEE 60802

IEC/IEEE 60802 based TSN promises to provide coexistence, higher network utilization and improved configuration tools compared to the standard unmodified Ethernet of today. The technologies of preemption, scheduling, universal QoS implementations, path reservations, and IEEE 802.1CB fault tolerance are being specified.

These technologies all rely on moving time synchronization standards up a layer from fieldbus specifications to IEEE 802.1. All devices that participate in IEC/IEEE 60802 communication need to have a common implementation and understanding of time. IEEE Std. 802.1AS-2020 will be the time protocol that drives time synchronization. IEC/IEEE 60802 TSN devices will also need to adhere to the same rules in processing and forwarding communication packets as defined in traffic schedules to participate in real-time (TSN) communication. Finally, all IEC/IEEE 60802 client devices will gain access to and run on an IEC/IEEE 60802 based network using the common language of YANG.

Time Sensitive Networking ISO-OSI model.

Application areas or markets

Beydoun said that IEC/IEEE 60802 TSN will likely be initially adopted in Automotive, Semiconductor, and Food/Beverage industries. These industries have a higher level of automation than average, tend to be early adopters of technology, and stand to benefit significantly from the ability to fully maximize their networks to take advantage of IIoT applications such as cloud machine learning via vision cameras while also supporting multiple real time automation networks.

“IEC/IEEE 60802-enabled TSN provides a unique solution to introduce Software Defined Networking to industrial networking in a standardized manner, while enabling deterministic converged transport. EtherNet/IP will release a best-of-breed solution when appropriately standardized by IEC and IEEE to take advantage of these benefits,” he added.

Technology benefits

An example of the benefit of IEC/IEEE 60802 TSN is being able to adapt CIP Motion by aligning the network with the motion control planner using a common notion of time. Once CIP Motion and 60802 are aligned, network transport can be facilitated using scheduling as necessary to meet the needs of the network and coexist fairly with existing traffic.

“Once you have a converged network regardless of network, device manufacturer, or device type, the door is open to more opportunity for saving on wiring, easier network management, cloud-based data analysis, a mixture of IT and OT traffic on the same network, and more comprehensive plant metrics among other potential benefits,” Beydoun said.

“Applications such as security cameras, cloud analytics and real time I/O data running over the same wire can become a reality. A more cohesive plant control network that can be better linked to enterprise level IT networks allows for better asset visibility, more opportunities for data analysis and production optimization, and less worker training and maintenance costs.”

Development timeline

Beydoun said that IEC/IEEE 60802 TSN is another possible step in the overall progression of interlinking devices together to make it easier to control, diagnose, and improve manufacturing processes. This technology journey started with the use of pneumatics, progressed to simple analog voltages over a wire, moved ahead to complicated digital signals, continued to common networked fieldbus implementations and now the next step is further network convergence through IEC/IEEE 60802 and other technologies.

“Convergence will give the opportunity for multiple fieldbuses to work together to allow end users to have better visibility into operations and to more easily implement their systems. TSN is just another phase in a journey to a plug and play control network that enables the highest order of manufacturing optimization and flexibility,” he said.

Individuals active in ODVA, IEC & IEEE are continuing to work to contribute to the IEC/IEEE 60802 working group that is identifying the TSN components that will ultimately be included in the joint standard. Both new and existing users will be able to take advantage of the low overhead nature of EtherNet/IP driven by close adherence to key IEEE Ethernet standards, leveraging of commercial off the shelf technology to the extent possible, and use of both UDP and IP technology depending on the use case.

The first edition of the IEC/IEEE 60802 TSN specification is expected to be available to the market in late 2023. EtherNet/IP is anticipated to have an IEC/IEEE 60802 TSN compatible specification available as after the IEC/IEEE 60802 TSN specification is released.

Key technology collaborations

An array of TSN implementation options

According to Greg Schlechter, president of the Avnu Alliance and Jordon Woods, director of the deterministic Ethernet technology group at Analog Devices, the toolbox of TSN protocols and capabilities defined under 802.1 standards offers an array of implementation options.

Determinism serves different purposes in different applications, and manufacturers across industrial, automotive, consumer, and professional AV industries will need a flexible selection of software and silicon to meet their particular use cases. Too much fragmentation, though, and TSN components will never achieve the economies of scale required for a sustainable ecosystem. For TSN to achieve large-scale adoption, TSN implementation must be as specific as needed for diverse applications while remaining as unified as possible at the silicon level.

The work currently being done at IEEE to define technical profiles for applications, 802.1BA for professional AV, 802.1DG for automotive, and 60802 for industrial, tells us how TSN implementations will be differentiated, but it also reveals how much they have in common at the network level. Avnu’s Silicon Validation Task Group is working to define test plans for base silicon profile conformance and interoperability. This interoperability would allow silicon component manufacturers to offer products that can serve diverse market requirements, accelerating the development of a broad TSN ecosystem.

Technology collaborations

Today, Avnu is collaborating with other protocol organizations such as CLPA, ODVA, OPC and PNO to develop a single test plan that could test for conformance with the IEEE/IEC 60802 profile for TSN for Industrial Automation. This would become a test plan that would be shared by all participating organizations and made available to the boarder Industrial Automation ecosystem to help drive interoperability at the TSN level on shared networks.

These organizations and Avnu all have significant roles in defining networks and communication protocols for the industrial automation ecosystem and this collaboration marks a commitment to develop an ecosystem of devices from different manufacturers that all comply with IEEE’s 60802.

Avnu’s Silicon Validation Task Group has been working to drive alignment on TSN interoperability at the base TSN capability level for two years. It recently made the first of its test plans available to members, with more on the way.

In December of 2021, four of Avnu’s silicon provider members, as well as other members from Avnu’s Pro AV working group, met at an in-person plugfest, gathering data on how well this test plan guarantees TSN interoperability in the real world. Data from this event is now being used to refine Avnu’s test plans. Ultimately, our goal is to offer a robust program of test plans, testing tools, and globally available certification so that silicon providers can develop TSN-capable components that manufacturers can trust to interoperate.

TSN application areas

Avnu believes that TSN has brought immense value to live sound applications, allowing dramatically simpler and more reliable network setup for touring and installed audio systems. The success of TSN in this context has paved the way for other industries – including industrial automation, automotive, avionics, and more – to seek to benefits from its deterministic capabilities.

While the use cases for TSN are diverse, all industries stand to benefit from alignment at the base silicon level. As profiles for various markets are developed, the commonalities across use cases are increasingly clear. Interoperability at the silicon level enables technological advancements to cross-pollinate from one market to another. For example, traffic shaping approaches used in professional AV could benefit industry 4.0 and vice versa. Interoperability at the component level will support capabilities coming online across industries.

Right now, TSN-capable silicon is highly specialized. By verifying base TSN capabilities at the component level in a common way, Avnu hopes to enable silicon providers to develop products for a broad customer base.

Alignment would mean that device manufacturers will get access to TSN-capable silicon faster, without having to wait for bespoke products targeting their industries to be introduced. In turn, silicon providers will be able to achieve better economies of scale, ultimately creating cost benefits along the entire value chain.

Expected impact and timeline

Silicon-level validation is crucial for the growth of a broad TSN ecosystem, and it must be built on true cross-industry alignment and rock-solid performance data. Avnu is moving quicky without rushing; we anticipate the launch of a silicon-level validation program within the year.

As far as when certified silicon will begin to impact the smart manufacturing market, silicon-level validation is just one – very important – step. There must also be software that enables the TSN capabilities from the silicon.

This is where specialization by industry is likely to occur – further up the stack. Still, having a common target for base TSN capabilities will make it much easier to develop such software roughly in parallel with silicon components, and make it easier to port that software to diverse targets. Alignment on a common goal will accelerate the entire industry.

OPC UA FX

Basis for converged IT-OT systems

According to Georg Stöger, Director Training and Consulting for TTTech Industrial, time-sensitive networking for industrial use cases has gained visibility both as basis for converged IT-OT systems using OPC UA FX (Field eXchange) and as an extension for several preexisting industrial networking technologies (PROFINET, CC-Link, EtherCAT).

“The basis for all these solutions and the key to wider adoption is created in the IEC/IEEE 60802, a project defining required capabilities and optional features for ‘industrial TSN’, including key aspects such as a security model suitable for use in IT and OT,” Stöger told IEB recently.

“These standardization efforts, along with the prototyping done in the OPC Foundation and the testing/certification related activities in the Avnu Alliance are shaping the common feature set and interoperability needed for existing and upcoming industrial TSN network devices and configuration tools. This includes static (“engineered”) as well as dynamic (“plug-and-produce”) systems and scenarios,” Stöger said.

Adding to this development, time-sensitive networking as a trend in industrial networking is not just based on IEEE TSN; other technologies suitable for use in industrial systems – notably 5G – are also being frequently subsumed under this term, which will drive even wider adoption of the technology.

TSN capabilities

Stöger said that time-sensitive networking comprises a wide-ranging set of capabilities which extend the possibilities of “quality of service” commonly used in Ethernet-based systems. The four main sets of capabilities provided by TSN are:

- A highly precise clock synchronization mechanism suitable not only for networking purposes but also any kind of time-sensitive application;

- A whole lot of mechanisms for network traffic shaping, network latency control, and bandwidth optimization in TSN networks; these “quality of service” mechanisms are typically implemented in the TSN switches and are compatible with regular (non-TSN) network equipment such as industry PCs and Ethernet-based I/O;

- Mechanisms for high availability networking providing various capabilities for redundancy in the network streams and synchronization; these mechanisms can be applied in combination or separately;

- Methods for vendor-independent configuration and diagnostics of TSN devices, including YANG-based data format definitions and configuration protocols; this allows for easier exchangeability and interoperability of network switches and various devices from multiple vendors within a single system.

Many TSN-based systems only utilize a subset of these capabilities e.g. to achieve lower latency of time-critical messages in a converged network.

Application and markets

Stöger said that IEEE TSN is not specific to any individual market or class of applications. However, some industrial applications have much more stringent requirements regarding quality of service in real-time communication and network latency control. TSN can help meet these requirements, so applications such as automotive in-vehicle communication and industrial motion control systems are at the forefront of defining the use of TSN-specific capabilities in the industrial sector.

“Not all the currently defined TSN capabilities are truly innovative; for example, clock synchronization and redundant message transmission have been available in Ethernet or in industry-specific implementations of Ethernet-based networks prior to TSN,”. Stöger said. “But IEEE TSN is the first set of technologies combining full Ethernet compatibility, deterministic or precisely time-based message handling, stream-based network redundancy, and vendor-independent configuration capabilities within the IEEE 802 standards family. This makes TSN the perfect solution for IT-OT convergence in many industries, for industrial edge platforms, and any architecture where the flexibility of Ethernet needs to co-exist with stringent real-time and determinism requirements in the same network infrastructure,” he added.

The unique value proposition of TSN is that it supports configuration methods, flexibility, and security mechanisms typical for IT networks, while providing performance and robustness typical for OT networks.

Impact on smart manufacturing

Stöger said that OPC UA FX forms the basis for smart manufacturing and smart factories by allowing devices from different manufacturers to seamlessly communicate with each other and reliably relay critical messages using real-time communications.

He said that the OPC Foundation FLC’s Controller-to-Controller (C2C) demo presented in December 2021 shows how the OPC UA FX technology enables seamless configuration and dynamic collaboration of four different types of controllers from a dozen vendors in a smart manufacturing application. The underlying specifications are in the release process and can be considered ready for use. Based on this progress, he expects that smart manufacturing solutions based on OPC UA FX for C2C use cases will already be announced in 2022.

“Due to the lower real-time requirements on the control level, TSN is not a mandatory element in the C2C part of the OPC UA FX specifications,” Stöger said. “It will, however, play a major role in the OPC FLC’s specifications for Controller-to-Device (C2D) communication, which are currently being worked on. TSN will be used in industrial applications where C2D communication – which typically has (sometimes very demanding) real-time requirements– coexists with other types of networking, including C2C and legacy communication.”

“We therefore expect that products and solutions based on TSN in smart manufacturing applications will be released in 2023. Other industrial communication technologies including TSN or based on TSN are on a similar trajectory,” he said.

“To implement smart manufacturing solutions, manufacturers first need to add TSN functionality to their devices. At TTTech Industrial, we provide a range of products that include IP solutions and network configuration software to enable the fast integration of TSN features into components, and the easy set-up of OPC UA FX networks,” he added.

Al Presher, Editor, Industrial Ethernet Book

Getting Your TSN Product to Market Special Report

“Getting Your TSN Product to Market” is a special report on Time-Sensitive Networking and CC-Link IE TSN technology sponsored by the CLPA.

Learn more

Industrial Ethernet 2022 Special Report

2022 Special Report in the Industrial Ethernet Book explores the latest technologies and trends in industrial networking including Single Pair Ethernet, Time Sensitive Networking (TSN) and IIoT software solutions.

Learn more