TechnologyMay 10, 2018

OPC UA standards driving process automation integration

Based on its future-ready and legacy-friendly design, true multi-vendor interoperability facilitation and an active technical community, OPC UA has gained broad industry acceptance and is well-suited to serve as a solid foundation for the Open Process Automation Forum to build upon to fulfill its vision.

OPC FOUNDATION STANDARDS are globally recognized and adopted by a wide range of organizations. Some examples of where OPC Foundation standards are used for horizontal and vertical data interoperability include Industrie 4.0, Namur, Industrial Internet of Things (IIoT), PackML, PLCopen, and various industries such as Oil & Gas, Machine Tools, Building Automation, Business Enterprise, and others.

OPC Unified Architecture (OPC UA) technology, has emerged as an interoperability standard for industrial automation achieves information integration and interoperability in industrial automation while maintaining the highest level of security, reliability and availability.

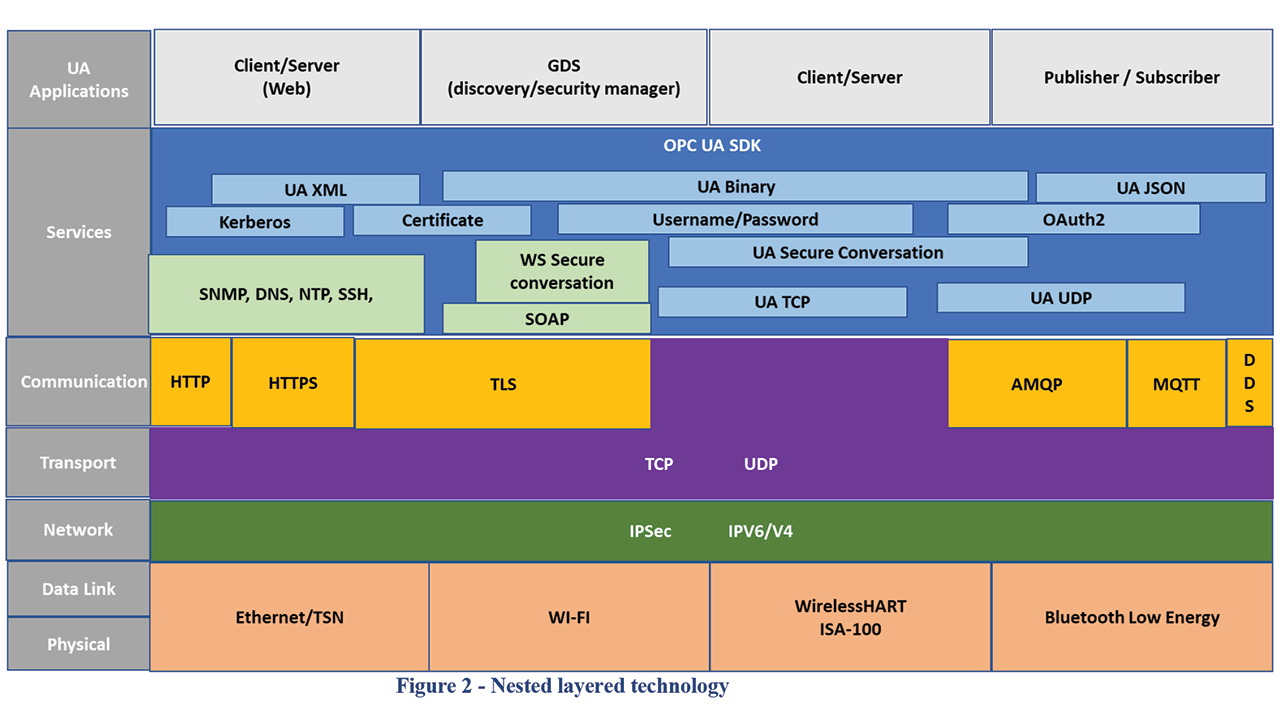

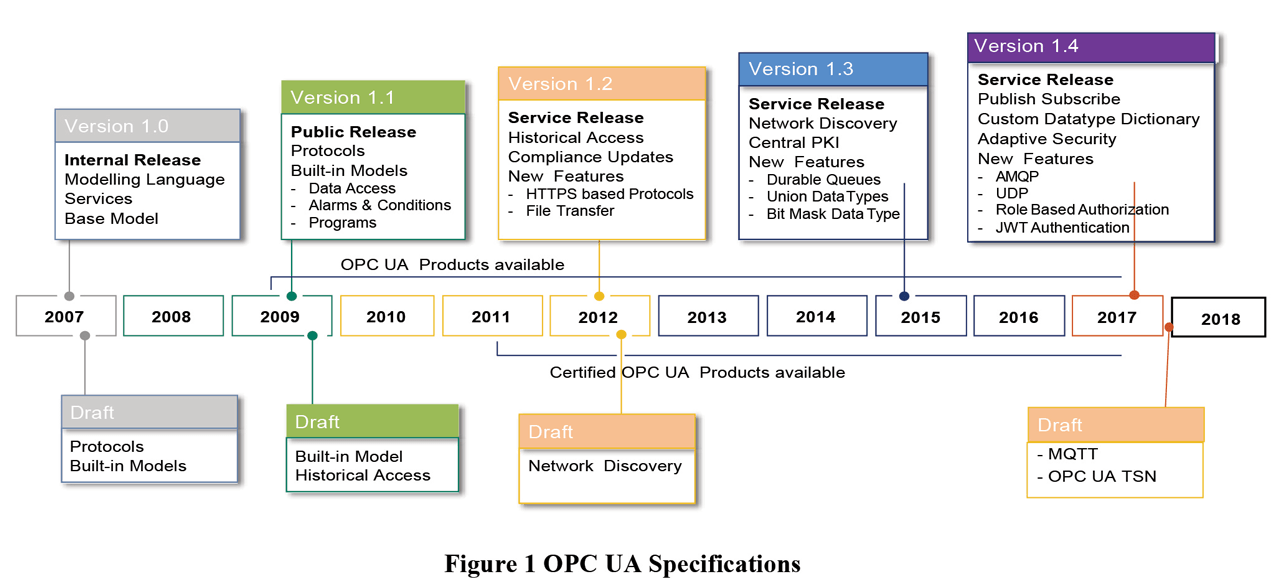

OPC UA technical specifications, developments and the timeline of approximately 10-12 years when OPC UA concepts began to evolve.

Standards for process automation

OPC UA is rapidly becoming the preferred standard for process automation integrating controls, information, enterprise systems, and the supply chain. The OPC UA standard leverages over 20 years of real-world industrial experience and know-how gained from work done on the OPC Foundation’s well-established first-generation interoperability standard OPC Classic. Picking up where OPC Classic left off, the OPC UA standard, achieves truly secure information integration and interoperability for the modern era.

True to its mission, OPC UA standard serves as a fundamental enabler for manufacturers, helping them achieve higher levels of quality, efficiency, and productivity to compete in a globalized economy.

It also serves as a foundation for other standards based consortia which require multivendor interoperability to fulfill their missions. The other consortia provide the information (industry specific knowledge and models), OPC UA provides the secure reliable transport and interoperability.

The Open Process Automation Forum (OPAF), a relatively new initiative with a vision that calls for multivendor interoperability as one of its goals. OPC Foundation has joined this initiative to lend it many years of experience. This article provides some background on why working with the OPC Foundation (and adopting OPC UA specifically) is a strong fit for the OPAF fulfilling its mission to deliver effective process automation solutions.

Legacy controls in IIoT era

As industrial enterprises address the lifecycle challenges associated with distributed control systems (DCS) that are still running after decades of operation, many recognize the emergence of a major juncture in the evolution of control automation systems. This present juncture is met with numerous questions that express both excitement and concern. For example, how do businesses refresh existing infrastructure yet advantage of rapid technological advances to improve production while protecting plant assets including the manufacturer’s intellectual property?

The full or partial transition of the DCS to an IIoT centric system architecture is driven by expected outcomes that enable access and analysis of more data and that promote seamless interoperability of multivendor components.

As a result, new initiatives are emerging to define an over-arching standard that incorporates the standards currently defined for communications interoperability (Foundation Fieldbus, HART, OPC, etc.) but also defines a reference and/or conformance platform that is standards-based, open, secure and interoperable.

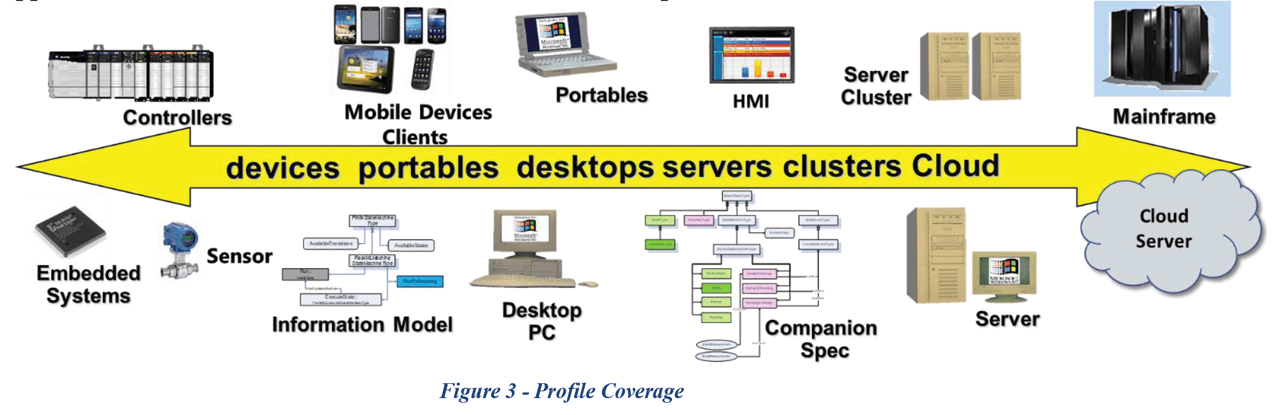

Profile coverage provides support for a wide range of hardware including field devices, portable and desktop computers, servers, clusters and ultimately the cloud.

Industrie 4.0, China 2025, and the Industrial Internet Consortium (IIC) are major initiatives that have been underway for several years and are primarily focused on practical IIoT standardization and deployment. OPC UA is a key component of these standardizations.

In September of 2016, The Open Group launched the Open Process Automation Forum (OPAF). The OPAF vision as stated on the Open Group web site FAQ is to define “a standards- based, open, secure, and interoperable process control architecture that:

- Enables access to leading edge capability

- Preserves asset owner’s application software; significantly lowers cost of future replacement

- Allows integration of best-in-class components

- Employs an adaptive intrinsic security model

- Promotes innovation and value creation

- Is applicable to both brownfield and greenfield facilities

- Is a commercially available system

The goal is to show why and how OPC UA can be applied to realize the Open Process Automation Forum vision. The first topic is a review of the key principles of OPC UA. The remaining topics demonstrate OPC UA’s role with respect to the Forum’s vision characteristics listed above.

OPC UA principles

The business value proposition for OPC is secure yet frictionless information integration and lower total cost of infrastructure ownership. The true worth of this value proposition can be validated based on the ever growing need to connect deeper into the shop floor or process automation system, with less effort, coupled with the need to easily integrate more types of data for faster and better decision making.

OPC Foundation’s commitment is to continue the evolution of its standards by expanding on the successful aspects of the OPC Classic standard to provide a forward-looking architecture with limitless usage opportunities. The timeline for the delivery of a set of specifications are also published through IEC 62541.

The timeline of approximately 10-12 years shows when OPC UA concepts began to evolve. Many OPC UA concepts started from a growing list of usage scenarios that could not be achieved with OPC Classic capabilities. The OPC Foundation itself, has evolved along with its products, to become a global organization that has remained true to its original mission to promote collaboration among users, vendors and consortia to create information transfer standards for multi-vendor, multi-platform, secure and reliable interoperability in industrial automation.

As an example of its commitment to broad collaboration, the OPC Foundation continues to sponsor numerous Interoperability Workshops (IOPs) and other events, which encourage and enable vendors to test the inter-connectivity of their OPC UA products and devices. These workshops provide an ideal testing environment for proving vendor to vendor interoperability, robustness, resilience, etc. In other words, IOPs provide a forum for open exchange of ideas and techniques among industry experts.

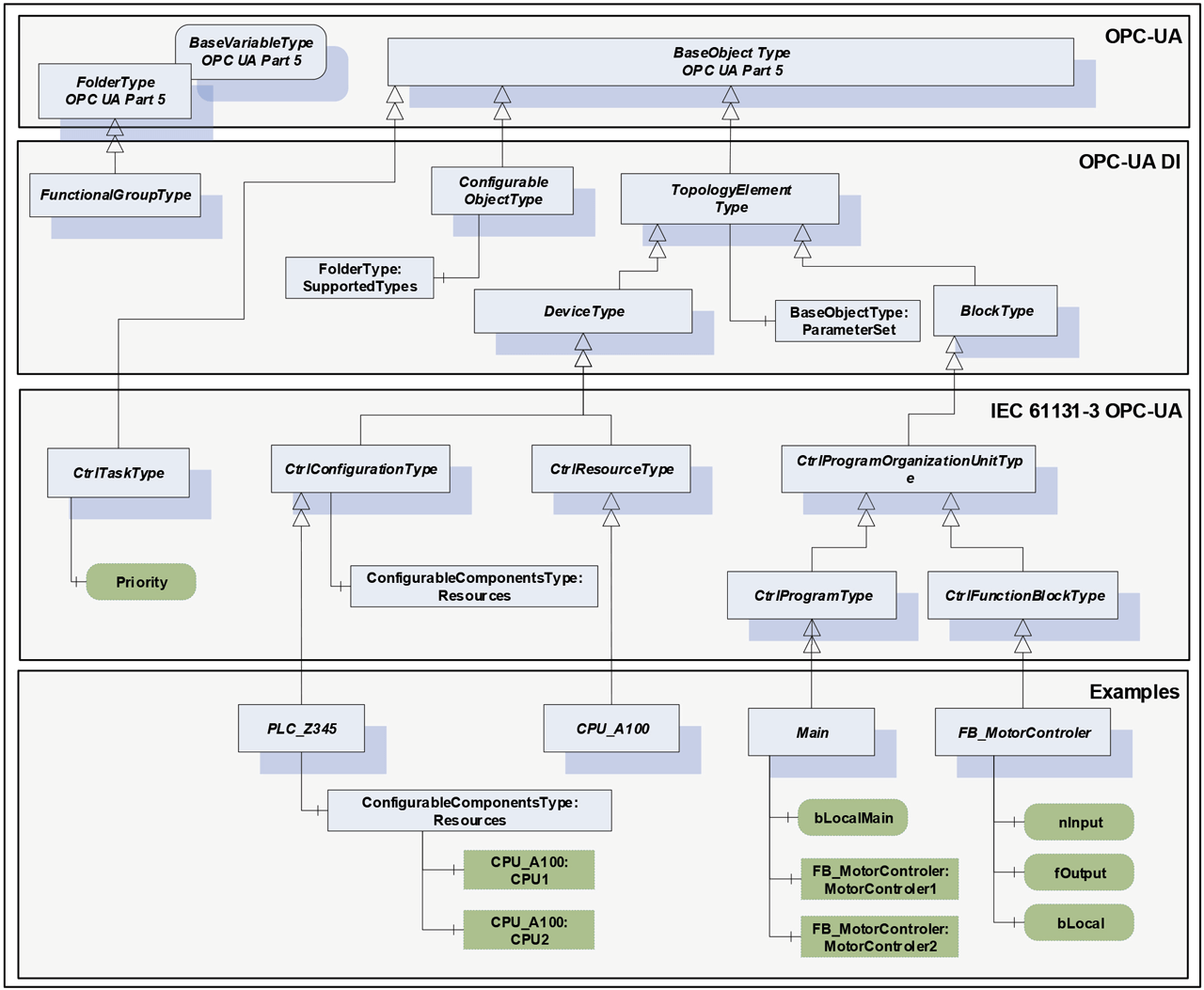

Diagram above illustrates the derivation of the OPC UA base objects and DI objects for formulating IEC-61131-3.

Design philosophy

The OPC UA architecture consists of data modeling and transport mechanisms driven by a comprehensive set of secure connectivity requirements. In other words, reliable communication that adheres to industry mandated levels of robustness and fault tolerance, platform independence, scalability, performance, and interoperability. OPC UA supports industry standard based security and access control.

To ensure OPC UA meets today’s and tomorrow’s technology challenges, the OPC Foundation based the OPC UA architecture on four key extensibility fundamentals:

Dynamic Data Modeling: OPC UA uses an object oriented, extensible information model and includes a complete set of associated services which, can further act on the information models.

Companion Specifications: OPC UA has the unique capability of facilitating the development of companion specifications as a way to unite the industrial automation landscape of multiple standards by enabling the standardization of how each is expressed in OPC UA.

Layered Technology: OPC UA is based on a set of layered and interchangeable technology mappings which protects against obsolesce in the face of continuous technical evolution. New transports, new security, even new communication protocols can be easily added/enhanced without changes to information models or applications.

Profiles: OPC UA functionality is broken down into defined groupings of functionality to allow implementations to be tested for specific behaviors during certification.

Each of these areas is examined below.

Dynamic data modeling

OPC UA information modeling mechanisms enable higher degrees of integration because there is a common model for all information. In other words, real-time data, historical data, alarms and conditions, and programs are layered upon the same object oriented common model.

An extensible type system is supported as well as the ability to expose metadata. Scalability from simple to complex models is easily accommodated. This same common model can be used as the base for other standard data models, commonly referred to as companion specifications.

The fundamental OPC UA information architecture includes a core address space model that supports the representation of information models in the address space. In this context, an information model is an organizational framework that defines, characterizes and relates information resources of a given system or set of systems.

This provides a streamlined approach for different data models that can be easily analyzed and turned into information. This allows OPC UA to provide an overarching information model that facilitates the inclusion of data and metadata from many different information models originating from different organizations.

At the lowest level, OPC UA has its own base OPC UA information models which can be found in parts 8 (Data Access), 9 (Alarms and Conditions), 10 (Programs) and 11 (Historical Access) of the specification set.

Multi-standard bridges

The OPC Foundation has an extensive collaboration program that allows companion specifications to be developed providing streamlined translation of various organizations’ information models directly into OPC UA.

Collaborations can either be internal to the OPC Foundation, external or a joint working group. The resulting deliverables from these collaborations are known as Companion Specifications. A Companion Specification refers to the definition of an OPC UA information model that represent information external to the core OPC Foundation. These information models can build on existing model or be unique for a given industry or vertical market.

The following is a partial list of companion specifications which are either complete or in progress.

- Device related

- PLCopen, FDI, FDT, ADI, DI, FieldComm

- Open-SCS, AutoId

- Oil and Gas standards

- MDIS, WITSML, PRODML, DSA-TS

- Manufacturing

- MTConnect, PackML, VDMA: Robotic, Machine Vision, EuroMap77

- Fieldbus standards

- ProfiNET, EtherCAT, Sercos, Powerlink, IO-Link, CC-Link, CAN

- Enterprise level

- MIMOSA, ISA-95

- Other

- BACnet, AutomationML

Layered technology always current

The design philosophy behind OPC UA is all about easily weaving inevitable evolutionary changes in the underlying technologies and standards (ex. encryption algorithms, transports, etc.) into a complete, cutting edge architecture that has timeless durability. OPC UA is also designed for complete backward compatibility allowing for bridging the gaps between legacy systems, today’s systems, and systems of tomorrow.

OPC UA transport mechanisms are designed for extensibility and are configurable depending on the overall system requirements. OPC UA provides a unique strategy to allow seamless interoperability across the multitude of transports for timeless durability from the past into the future.

The OPC UA services are located just above the Communication layer. Notice the multiple OPC UA protocols identified within the Services layer, from left to right.

- UA Binary is optimized for performance.

- UA XML enables Web access.

- UA UDP or UA Binary with UA JSON are new transport mechanisms extending the set of transport mechanisms to enable publish subscribe. Once Time Sensitive Networking is available the combination of OPC UA and TSN will solve use cases requiring deterministic real time.

This list of transports exemplifies the future-proof characteristic of the OPC UA architecture. OPC UA architecture sports many other robust mechanisms such as:

- Heartbeats and sequence numbers to ensure that messages are transported consistently

- Automatic buffering to ensure resiliency so data is not lost as a result of disconnections

These functions are provided above the communication to ensure robust communication is available no matter what the underlining transport is.

Security is inherent to the architecture, and secure mechanisms are built on industry standards, yet are designed to adapt to this rapidly changing technology.

Profiles: units of functionality

OPC UA Applications can range for small embedded devices to large cloud applications, they can be servers or clients or server and client, implementing multiple information models.

To allow easy testing and verification of functionality OPC UA defines Profiles. Profiles group functionality into testable groupings. Profiles are the basis for certification of applications. An application can expose the range of profiles that match the functionality required in the application. This can include information model related profiles.

The next sections explore OPC UA functionality and how it could be mapped to the Open Process Automation Forum vision.

Access to leading capabilities

The separation of the data model from its underlying technology architecture is a core strength of OPC UA. This separation is fundamental to adapting to new technologies including those defined for security and communication protocols.

Even though underlying technologies may change, the integrity of the information model remains intact. Applications typically do not need to be changed to implement new underlying technologies.

Best-in-class components

Standardized information models lead to lower costs and enable integration of best-in-class components. Best-in-class because OPC UA promotes collaboration among the industry’s best domain experts to define the models. For example, the OPC Foundation and PLCopen collaborated to define an information model to represent IEC 61131-3.

Not only does the OPC UA PLCopen information model derive from OPC UA base objects, it also leverages the information model of the OPC UA Device Integration (DI) specification. Take a look at the figure above which illustrates how we derived the OPC UA base objects and DI objects to formulate a solution incorporating IEC-61131-3.

The OPC Foundation works closely with Collaboration organizations to help them leverage OPC UA technology and generate best in market companion specifications. The OPC Foundation is prepared to extend the OPC UA standard to provide the support for the best new functional requirements that may emerge from companion specifications.

Adaptive intrinsic security model

OPC UA was architected with security as a key concern, it addresses security at all levels of the architecture. It was designed with the assistance of security experts to ensure that it makes use of the latest technology and that it is designed with evolution in mind.

It is a well-known fact that security and security requirements are forever changing, as process power increase, new security holes are discovered, new security algorithms are invented, even changing security requirement all result in updates to security architectures. OPC UA was designed with this in mind. Communication stacks can be updated with new security features without affecting the base application and information model (no application code changes needed).

OPC UA security is a good example of OPC UA plug-and-play interoperability that allows new things to be added while still guaranteeing complete, reliable information integration and interoperability between new and legacy applications and devices.

The OPC Foundation works directly with numerous organizations to validate all aspects of the OPC UA standard, including the security model that is built into its base. Organizations such as NIST and Germany’s BSI (for use with Industrie 4.0) have reviewed and recognize OPC UA for its comprehensive set of security features. For example, the German government’s BSI generated an in depth analysis of OPC UA security which, validated that OPC UA provides both the theoretical and practical security features that meet the extensive security requirements needed for a standard to serve as a cornerstone for Industrie 4.0 data connectivity.

Promoting innovation and value

Technological innovation and change will continue as end users and suppliers look for better ways to increase revenue and lower expenses. The OPC Foundation actively evaluates leading-edge technology innovations with an eye to enhance the OPC UA interoperability vision to solve future real-world problems.

The OPC Foundation recognizes the importance of delivering the highest quality specifications, technologies, and certification processes for OPC UA to best serve the broad needs of our members and partner organizations.

Integrating leading edge technology, while still maintaining the strict security requirements, certification goals and backward compatibility as migration paths is part of the requirements that the OPC Foundation maintains.

The many collaborations and resulting companion specifications ensure that OPC UA can be used to exchange not just data but state of the art information between systems. The information modeling capabilities of OPC UA allow vendors to utilize their expertise in specific fields while utilizing the secure robust communication capabilities of OPC UA to interchange the information.

Applicable to brownfield facilities

In the near term, OPC Classic is likely to be more prevalent in brownfield sites for usage scenarios involving HMI, SCADA, and advanced applications.

Although OPC UA provides a far richer feature set and is more flexible than OPC Classic, many of the concepts of existing OPC Classic specifications are maintained within OPC UA. This ensures that many features and concepts well-known to users of OPC Classic can be carried over to OPC UA.

The design of OPC UA accounts for deployment models with interoperability between OPC Classic and OPC UA. These interoperability components are known as wrappers and proxies. Deployment of an OPC UA wrapper is provides communicate between an OPC Classic server and a native OPC UA client.

Alternatively, deployment of an OPC UA proxy is provides communicate from an OPC Classic client to a native OPC UA server. OPC UA was designed to address the various scenarios users may encounter when migrating or blending OPC Classic and OPC UA architectures.

Open source components

OPC UA Applications can utilize Stacks and SDK to simplify implementation. Stacks provide the communication/Security aspects of OPC UA which include the mapping to transports like TCP, HTTPS, AMQP. SDKs add the standard interactions like reads, write, subscriptions provided by the services described in the OPC UA specification.

They even provide infrastructure for information model management. Together they greatly simplify OPC UA application development and help ensure interoperability.

OPC UA samples, stacks and SDKs are available as Open source and as Commercial offerings. The OPC Foundation provides samples and stacks as open source via GitHub from which members can build commercial products.

Commercial SDKs provide optimized solutions for markets (better performance) and better support. They are available from numerous vendors, many of whom have been associated with OPC Foundation since its inception.

Inter-standard body collaboration

The OPC Foundation is an open standard. As such, the OPC Foundation provides its specifications freely to both OPC Foundation members and nonmembers and makes the technology for implementing OPC UA available as open source where the OPC Foundation maintains the deliverables and extends the base to support future innovations.

The OPC Foundation also works with commercial toolkit vendors who provide complete support infrastructure to allow other vendors to rapidly develop and deploy OPC UA based products. Some toolkit vendors actively use of the OPC UA base stacks that are developed for multiple platforms and are developed in multiple languages while others develop their own base stacks.

The OPC Foundation works collaboratively with these vendors to deliver standardized deliverables for seamless interoperability.

The OPC Foundation works with all of the collaboration partners to ensure all of the companion specifications also have complete open-source reference implementations to demonstrate that the specifications actually work. The OPC Foundation develops practical standards that are proven and adopted.

The OPC Foundation offers certification testing services for OPC UA products. The goal of these services is to improve product quality while ensure interoperability. A separate compliance working group is dedicated to defining the features of the Certification program. Consult the OPC Foundation website for information related to product certification.

The OPC Foundation recognizes the significant contributions from various parties working closely together to ensure harmonization across application spaces to provide the solid infrastructure needed to facilitate seamless data and information exchange between disparate devices and applications. Examples of some include the OPC Foundation Board of Directors, Technical Advisory Council, OPC UA core working groups, and all the collaboration partners.

Companies like ABB, Beckhoff, Honeywell (including MatrikonOPC), Siemens, Schneider, Rockwell, Emerson, Yokogawa, Microsoft, SAP, BASF, GE, Mitsubishi, Kepware (PTC), Endress and Hauser, and many others provide resources to the many working groups and companion standard groups. (this is a partial list of the set of the 100s of companies that have been working on the OPC UA technology over the years).

Oil companies and chemical companies are developing standardized object models that directly plug into the OPC UA architecture. Especially notable is the dedication of all of these companies that have formed a community of end-users and suppliers closely working together under the umbrella of standards organizations.

Summary

The OPC Foundation’s mission to develop the best specifications, technology, and certification processes to achieve multivendor, multiplatform, secure, and reliable information integration and interoperability between disparate devices and applications. Taken together, this facilitates meaningful data sharing between components in the deepest reaches of the shop floor, the enterprise, and the cloud.

The OPC Foundation and its member community of volunteers has invested literally thousands of person years of work to get both OPC UA and all the companion specifications to come together to create a ready-made, standards-based interoperability foundation which, when adopted, gives vendors and end-users a competitive advantage when compared to starting from a different new or existing standard.

The OPC community also continues working actively to make sure that all systems, from legacy systems of yesterday and the systems of today to seamlessly plug-and-play with the systems of tomorrow while leveraging all of the technology innovations yet to come.

Based on its future-ready and legacy-friendly design, true multivendor interoperability facilitation, and active community OPC UA has gained broad industry acceptance and is well suited to serve as a solid foundation for the Open Process Automation Forum to build upon to fulfill its vision.

The OPC Foundation looks forward to collaborating with the Open Process Automation Forum to help leverage OPC UA to address the Forum’s complex interoperability requirements and use-cases.

The OPC Foundation encourages everyone to join and participate in the OPC community. More information about the growing number of collaborations that continue to be added in the industrial automation sector and beyond can be found on the OPC Foundation website.