TechnologyMarch 30, 2021

Industrial Ethernet Switches Industry Trends

Industrial Ethernet switches and routers are effective building blocks for corporate and manufacturing networks worldwide. In this special report, industry experts provide information on the latest trends in new products, solutions to improve network management and support for new technologies such as TSN.

A new generation of ethernet switches is designed for industrial applications with goals of leveraging available bandwidth, increasing flexibility and implementing new technologies such as Time Sensitive Networking.

In this article, a series of industry experts provide insights into the trends shaping Industrial Ethernet switches and routers. The impact of digital transformation, and much higher numbers of connected devices, is resulting to a constantly growing number of “intelligent” network-capable components in the production environment and increases in the amount of network data.

Modularity and scalability

A key trend in Industrial Ethernet switches is an emphasis on solutions that provide increased levels of modularity and scalability. This approach is enabling true network versatility with just a single, modular platform. Industrial switches are offering multi-port Gigabit mix-and-match modularity that is ideal for flexible network expansion. Using highly durable housings and a compact footprint, these switches are designed to fit in confined spaces and operate in the harsh environments such as those commonly found in substation, mining, and oil and gas applications.

The system design enables switches to offer a variety of hot-swappable media modules (RJ45, SFP, PoE) and power units to provide greater flexibility and availability, especially for continuity-critical operations.

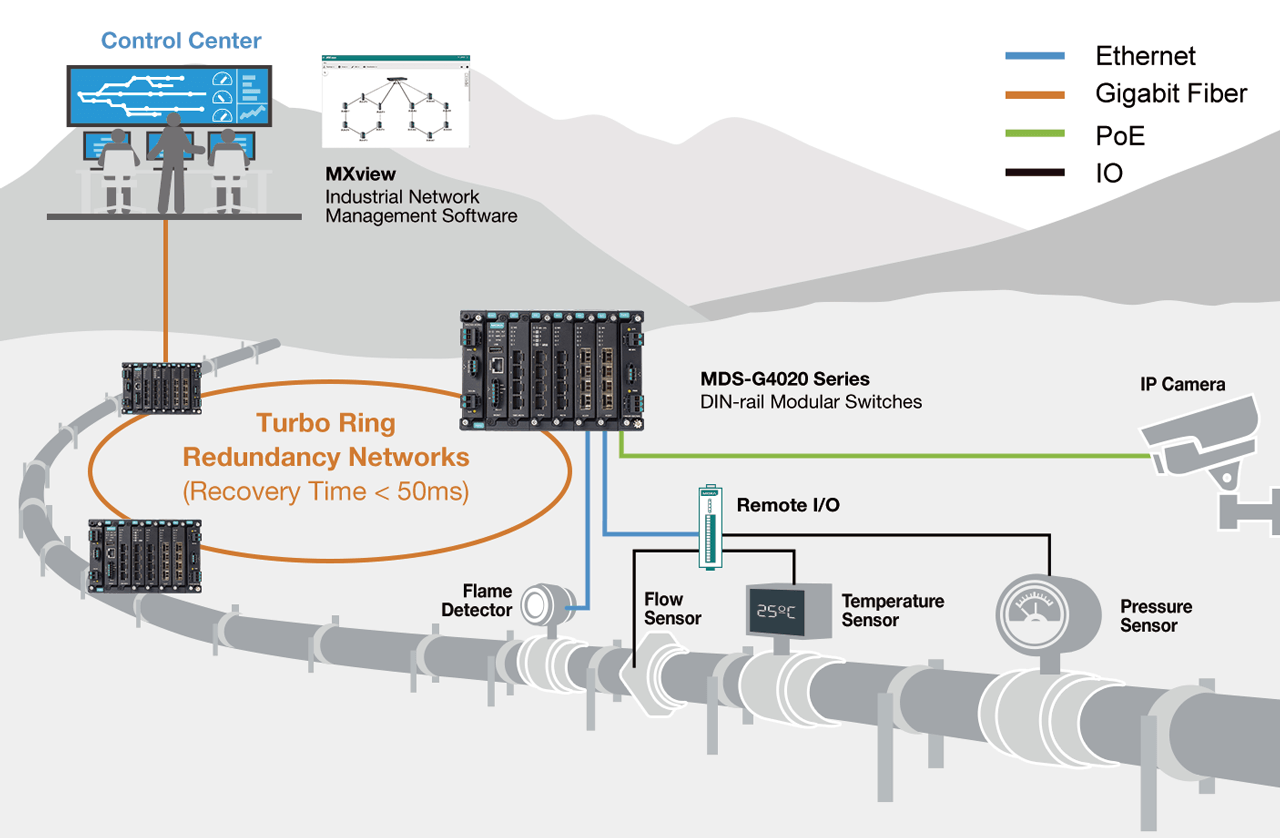

For oil and gas companies developing a fully digitalized oilfield, switches play a key role in building a reliable network backhaul for monitoring the various integrated pipeline subsystems including IP surveillance, ventilation and fire control.

Field Monitoring for Pipelines

The MDS-G4020 Series from Moxa is an example of a fully modular platform that can be outfitted with fiber interfaces to connect pipeline subsystems to a remote control center over long distances, while providing wire-speed Gigabit bandwidth to aggregate and process video, voice, and data transmissions from the field equipment smoothly.

Featuring a fanless, rugged design that is ATEX Zone 2 and C1D2-certified, the MDS-G4020 Series can withstand the extreme environmental conditions common in oil and gas applications. To consistently monitor remote pipelines, the solution provides 50 ms Gigabit network recovery times to ensure network resilience and reliability. In addition, the compact form factor enables installation in DIN-rail cabinets while the high-capacity PoE budget can be leveraged to deploy and power nearby substation field equipment including IP surveillance cameras and valve controls.

In order for oil and gas companies to develop a fully digitalized oilfield, it is key to build a reliable network backhaul for monitoring the various integrated pipeline subsystems including IP surveillance, ventilation, and fire control.

As the pipeline extends many kilometers away from the control center, companies are looking for a reliable and sustainable solution that can aggregate all data from the field sites and establish a high-bandwidth communications backhaul connection to the remote compressor stations and network operation center.

In the control center, the MXview network management software provides real-time network status information and makes it easy for engineers to monitor the network and provide timely information for field-site engineers, simplifying maintenance and maximizing uptime.

Networking megatrends

According to Jan Aulenberg, product manager network technology at Phoenix Contact Electronics, there are currently many trends in the field of industrial network technology that are intended to enable end-to-end networking from the sensor to the cloud. Common to all technologies is the goal of ever greater networking of devices, areas and industries.

“The resulting increase in communication will become a major challenge in the future, as it negatively affects the real-time capability of networks,” Aulenberg stated. “The Time Sensitive Networking (TSN) technology has been developed to ensure that the real-time properties of industrial networks can still be maintained. TSN is a set of standards that includes rules and mechanisms for achieving real-time capability in a standard Ethernet network.”

This includes, for example, control and prioritization of the data streams. Individual requirements of applications such as reserved bandwidth, time synchronization or low latency are taken into account and also guarantee the real-time capability of the system. This ensures that despite the increased data traffic in the network, one application neither interferes with nor can be interfered with by other communications.

Since Industrial Ethernet Switches play an important role as communication nodes for future TSN networks, Phoenix Contact has developed the new FL Switch TSN 2300 as its first Ethernet switches for TSN.

Advantages of TSN switches

“The new switches enable the setup of time-synchronous applications and ensure real-time communication and increased availability in automation networks,” Aulenberg said. “They create convergence between information technology (IT) and industrial operating technology (OT) by implementing both real-time-critical data and data-intensive applications (e.g. video streams) over a common Ethernet line without interfering with each other.”

Specifically, the devices ensure precise time synchronization with other network nodes thanks to support for the IEEE 802.1AS standard, or the gPTP protocol. For highly efficient communication of real-time critical OT and data-intensive IT traffic, the switches support the Frame Preemption function. This function enables the lossless interruption of the ongoing transmission of a large Ethernet frame until a later point in time, in favour of real-time critical data. Thanks to TSN streams, communication paths can also be selected and line capacities reserved.

Profinet TSN profile

Aulenberg added that, in total, the switches fulfill the requirements for supporting the Profinet TSN profile. At the same time, the FL Switch TSN 2300 enable user-friendly TSN configuration via Profinet 2.4 engineering.

This comprehensive managed switch feature set also makes universal use of the TSN switches possible in classic applications. Users can therefore initially implement conventional applications with the FL Switch TSN 2300 and benefit from the advantages of TSN at a later date without having to replace the communication nodes.

Application challenges

Aulenberg said that the communication of real-time-critical applications (e.g. motion control) and data-intensive applications (e.g. video streams or IT systems) is usually implemented in separate networks to prevent mutual interference. However, the increasing flexibilization and digitization of work processes require increasing networking of IT and OT and thus a merging of the previously separate systems.

“The challenge for plant planners and operators in the future will therefore be to structure and prioritize critical and non-critical data traffic in such a way that neither real-time characteristics nor performance are impaired,” he added. “As a result, it is foreseeable that TSN will be relevant for almost all industries and automation applications in the future.”

Making the transition to the new TSN technology as smooth and convenient as possible for users and getting one step closer to comprehensive, end-to-end networking is a major goal of Phoenix Contact. For this reason, the company participates in all relevant standardization organizations, such as the OPC Foundation or PI-International, and is actively involved in implementing the standards developed in IEC/IEEE-60802. The FL Switch TSN 2300 is only the first step towards a consistent TSN product portfolio with further devices and system solutions, but already it offers the possibility to benefit from the advantages TSN offers today.

One trend in the latest Industrial Ethernet switches is support for Time Sensitive Networking.

Speed, flexibility and security

Michael Lefeuvre, Product Marketing Manager- Europe for Red Lion Controls, told IEB that the prevailing technical trends for Industrial Ethernet switches are a focus on increased bandwidth, application flexibility and meeting security requirements.

“We see a trend towards Gigabit connectivity as a standard even for edge devices,” Lefeuvre told IEB recently. “Additionally, communication will be prioritized in support and compatibility with industrial real-time Ethernet protocols such as PROFINET, Ethernet/IP and TSN.”

“It is also important to have protection against unauthorized network ingress and communication spying. Advanced security tools supported by industrial network assets such as ARP inspection or VPN are common in order to protect the enterprise network system,” he said.

The key is that new advanced technologies must be made accessible by field engineers to improve the assistance in configuration and monitoring. Assets are designed to be compatible with the automation software or be configurable by using a graphical user interface.

Technology impact on applications

Lefeuvre said that the emergence of Gigabit connectivity enables enterprise networks to use their full communication potential, and it will also open opportunities to add high-resolution videos. Advanced real-time Ethernet protocols in best conditions makes the communication reliable and stable regardless of the devices demands. So, optimization of network assets is needed.

“Security tools enable the network to detect any ingress and instability. They are improving safety, privacy and uptime in production,” he added. “Intuitive and assisted solutions increase the amount of people who handle these key technologies. They learn how to develop new solutions using business standards without needing networking experts.”

Challenges for applications

One impact on new innovations in switch technology is that every sector is investing in Industry 4.0 projects and, because of that, the amount of data transmitted by networks is increasing. A good example is video surveillance where high bandwidth is required for effective remote monitoring.

“Gigabit connectivity with highest network bandwidth will calibrate to support new traffic,” Lefeuvre said. “On the production/machine level, data from a PLC has more priority for real-time communication such as web pages or Email. Manufacturing would be more stable and efficient if you can prioritize the individual traffic by assets.”

Nevertheless, network cyber-attacks and inattention errors can have a big influence on the network uptime. Detecting unexpected connection or exchange to avoid inappropriate actions is important. Lefeuvre added that the ability for small structure/companies to implement advanced tools themselves for highly secured and reliable Ethernet must be supported.

Impact of digitization

According to Hannes Barth, Vice President – Business Line Industrial & Rugged Networks for Siemens, Industrial networking trends are influencing the development of the latest generation of Industrial Ethernet switches and routers, as suppliers develop solutions that respond to the need for higher performance, diverse application requirements and effective solutions.

The goal of the rapidly advancing digitalization of the industrial world is to make all processes along the value chain more transparent and more efficient through automation. This leads to a constantly growing number of “intelligent” network-capable components in the production environment and to sharply increasing the amount of data.

“As a result, there is a growing need for high-performance, industrial-grade network technology to ensure coordinated transfer and processing of all data,” Barth told IEB recently. “The ‘digital factory’ places significantly higher demands on network components in OT than it is the case in IT.”

“Beyond the issues of integrity, reliability and robustness, it is primarily issues such as availability, determinism and security in the industrial environment that concern the operators and users. Compared to IT security, OT has to use other protective measures. Industrial security, for example, uses the defense in depth concept in accordance with the standard IEC 62443,” Barth said.

Another issue he cited is also becoming increasingly important: flexibility. And as a result, two aspects are being incorporated into future Industrial Ethernet switches and routers. On the one hand, it must be possible to flexibly integrate end devices into the network regardless of the time and space without major wiring.

“The latest Power over Ethernet standard offers, for example, a convenient solution to address this. On the other hand, flexibility is also supported by greater intelligence in end devices and network components. They have to provide, for instance, edge functionality that is easy to administer for users,” he added.

Technical benefits

To be able to implement holistic OT networks, a broad portfolio of network components is required. Industrial Ethernet switches and routers are available in unmanaged and managed variants, as well as suitable for Layer 2 and Layer 2/3, from the cell to the aggregation level and even into the industrial backbone.

Barth said that, even at the cell level, high-performance Industrial Ethernet switches with up to 10 Gbit/s ensure sufficient bandwidth to connect machines and plants to the OT network. This performance can now also be combined with the latest Power over Ethernet standard, IEEE 802.3at. With up to 60 watts of power per port, even data-intensive end devices such as Wi-Fi 6 WLAN access points, HD cameras or even the latest 5G cellular routers can be flexibly integrated into the production network with just one cable for data and power.

He added that Industrial Ethernet switches with certifications such as IEC 62443 ensure the required data security in the OT area as well. This standard from the German TÜV enables operators to implement secure system architectures, which significantly increases the overall security of a plant. Network components with edge functionality represent an investment in the future. Equipped with additional data storage, application-specific software can be installed on them depending on individual customer requirements and also flexibly integrated into an edge ecosystem.

Facing innovation challenges

“Digitalization is finding its way into all areas of industries – from discrete manufacturing and process industry and electric power,” Barth said. “In this context, one major aspect stands out: mobility. Over the past decades, the use of radio technologies in industry has increased rapidly. Completely new solutions will be created for industrial applications in the next years, especially with the emerging 5G cellular standard.”

Whether it is for ports, in tunnel applications or in intralogistics – industrial components – regardless of whether wireless or wired – must be able to exchange data with the industrial network reliably, but also securely.

“As the backbone of the production network, Industrial Ethernet switches and routers must therefore provide several aspects: Robustness, security, performance and flexibility,” Barth concluded. “The latter in particular is reflected in the way industrial applications will be implemented in the future. The increasing intelligence of end devices also makes it possible, depending on the production process currently taking place, to install the appropriate user software on the devices and reduce the amount of hardware required.”

Particularly in industries such as specialty chemicals or pharmaceuticals, in which small quantities are often produced individually, this provides great potential for savings. Industrial Ethernet switches and routers must ensure that the user software is also available ad hoc at the desired time in different areas of the industrial network.

Expansion of connected devices

Patricia Costa, Product Marketing Manager for Cisco IoT, told IEB that the challenges of increased digitization and the number of connected devices expanding exponentially are driving the need for solutions that support increased levels of automation.

“Customers are rapidly digitizing all aspects of their business to improve operational efficiency, reduce downtime and increase employee safety. But digitization comes with challenges,” Costa said. “The first challenge is security. As the network expands to connect more and more devices, the threat surface also increases, which impacts the organizations’ ability to identify and prevent risks.”

A second challenge is asset deployment and management at scale. While the number of devices being connected is growing exponentially, resources aren’t. The result is that organizations need a solution that supports automation as much as possible. Plus, new technology advances are driving the need for both higher bandwidth and Power over Ethernet (PoE) solutions.

According to Costa, high volumes of data from hundreds of devices need to be moved to datacenter and cloud in real-time for analytics. One such example is the deployment of the latest high-definition cameras such as 4K, 8K and Point-Tilt-Zoom.

High-bandwidth downstream is also needed. As an example, connecting high-speed conveyor systems, automated guided vehicles and robots to assist human staff requires fast and reliable wireless connectivity such as WiFi 5 Wave2 and WiFi 6. Many connected devices such as digital signage, HD cameras, wireless access points and Point-of-Sale terminals also need to be powered by PoE and require high wattage.

“Manufacturing and utilities plants, roadways, warehouses, distribution centers, etc. are increasingly becoming more automated to achieve more efficiency, reduce downtime and improve personnel safety and productivity,” Costa said. “Secure, fast, reliable connectivity is key to realize the benefits of automation as downtime caused by network and security issues can have serious consequences and significant impact on revenue.”

Routers leverage cellular technology

According to Harpartap Parmar, Senior Product Manager at Contemporary Controls, there is an industry trend that includes use of cellular technology in the newest generation of industrial routers.

“The adoption of cellular technology is the biggest trend in the latest generation of Industrial Routers. This includes the LTE technology for high speed networks from CAT1 onwards to the inclusion of LTE-M and NB-IoT modems for access to low data throughput sensors and devices,” Parmar stated. “The high-speed cellular routers can act as backups for internet access if wired internet access is interrupted and provide continued operation and accessibility.”

Parmar added that s7 support for aggregating data on these routers and gateways, along with processing data as an Edge device on the routers, has become popular. The use of common platforms like Linux provides additional capabilities for custom applications to be included on them by the end customer that were only possible on a PC before. Additional protocols like MQTT for cloud integration are also supported, and VPN support is also becoming standard on the new routers for secure remote access and IIOT applications.

Focus on integration simplicity

“The industrial routers with cellular connectivity are providing a means for quicker integration at the job site,” Parmar added. “There is a requirement for access to devices without integrating them with the IT infrastructure and the cellular connectivity provides that.”

“The new routers have enabled access to all sorts of application for small to medium size businesses whereas the expense for earlier devices was cost prohibitive for them,” he added.

These new solutions are also easy to setup and configure providing security benefits. The ability of cellular networks to not be on public internet or to only have outbound connections is paramount importance for some applications, and this allows them to only provide data updates without the ability to local device access for security.

Remote applications

“The greatest benefit can be seen in for applications in remote locations where wired internet connectivity was not possible before,” Parmar said. “The cellular routers have enabled multiple applications from managing and troubleshooting solar farms, wind turbines to name a few instances.”

He also noted that processing data at the edge, and only passing the relevant information to the cloud, has resulted in cost savings. The diagnostics and analytics at the edge allow preventative maintenance to be performed resulting in no downtime.

The use of VPN technologies has enabled the use of applications from the home or office rather than having to leave a dedicated PC at the site for some applications. This has resulted in significant licensing and hardware cost savings as well.

Focus on “lean” switches

“As more devices on the factory floor are Ethernet enabled, plant engineers and technicians are in need of tools to help them increase network availability, improve network security all while reducing costs,” Charlie Norz, product manager automation at WAGO told IEB recently. “Controls engineers are asking for products that can help them with network performance and reducing downtime without creating more complexity.”

WAGO has developed a line of new lean managed switches that can help users with enhancing network security, increase network availability and reduce troubleshooting time. These streamlined “lean” switches provide users with all of the industrial networking features they need, without all the non-used, IT features typically found in managed switches.

“Controls engineers are looking for innovative solutions to enhance network functions while reducing system complexity,” Norz added. He said that lean managed switches are focused on providing all the features needed for industrial networking by offering “a network health dashboard that uses traffic light indicators for instant recognition of a potential problem”.

In addition, a topology map provides users with an easy-to-read map of connected devices and their health. Plant floor operators, technicians and engineers, as a result, can use these tools to quickly track down any networking issues.