TechnologyNovember 12, 2019

Building a future-proof data processing solution

Developing efficient, reliable, and maintainable data handling as part of an IoT solution presents challenges. System integrators looking to deploy IT solutions in the Industrial IoT world are faced with requirement specifications and customizing these applications to suit specific industrial automation (IA) requirements.

Most Industrial Internet of Things (IoT) discussions have been about connecting new devices and rapidly bringing them online. But with the implications of bringing such a large number of devices online, namely the need for efficient methods to collect information from these devices, the question is how to handle the large amount of data collected from these devices.

Industrial IoT solutions are judged on their ability to adapt to various data acquisition needs and how they can transform the data collected from devices into useful business insights that can help decision makers. What makes an Industrial IoT solution truly stand out is the flexible data handling possibilities that it can provide.

However providing efficient, reliable, and maintainable data handling as part of an Industrial IoT solution presents significant challenges because of the very nature of data-management solutions that exist today, which are designed mainly for information technology (IT) applications. System integrators looking to deploy IT solutions in the Industrial IoT world are faced with complicated requirement specifications and have to spend a lot of time and money customizing these applications to suit specific industrial automation (IA) requirements. In the following sections, we will discuss some of the key challenges of converging IT solutions with the Industrial IoT.

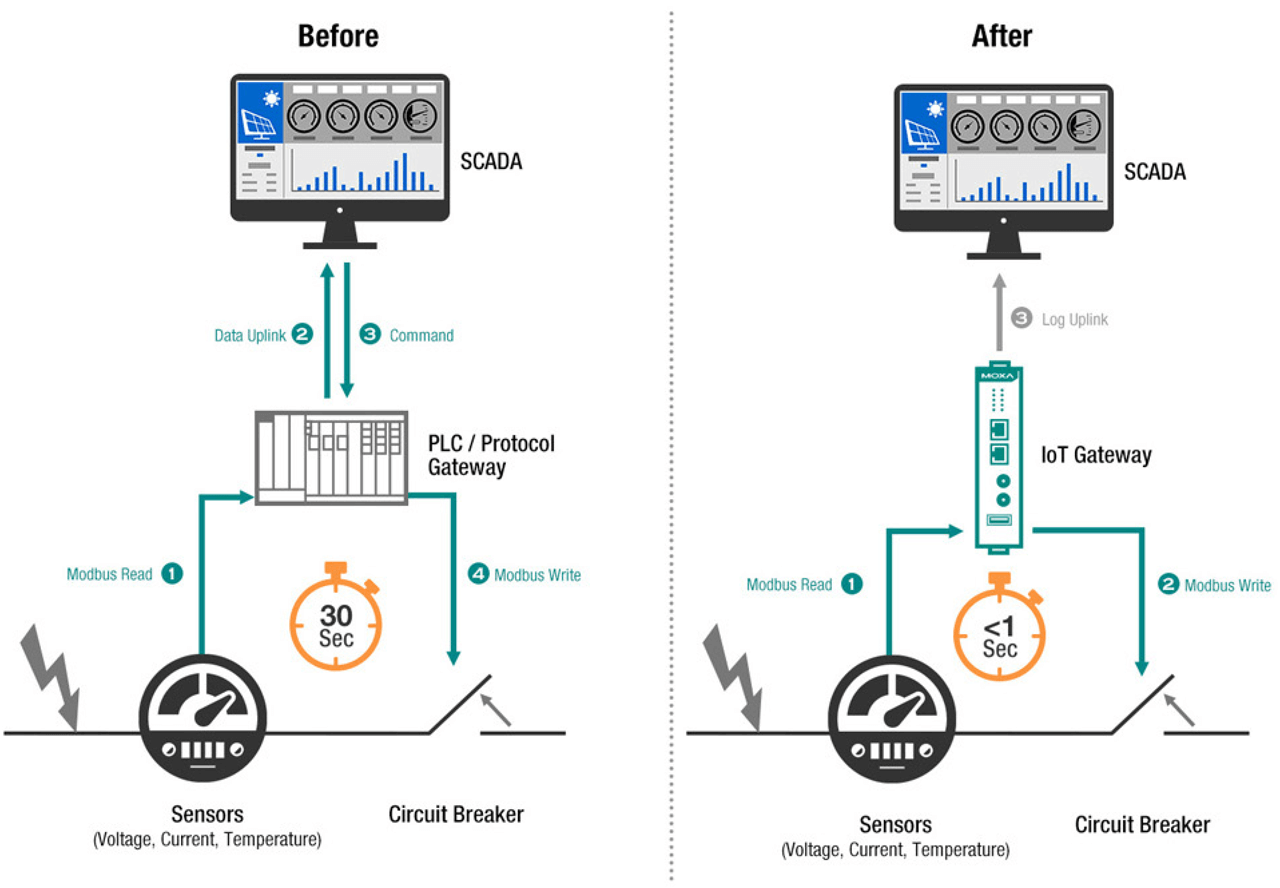

An intelligent IoT gateway or an intelligent edge device results in faster decision making. A centralized architecture where data is sent to the SCADA system for processing does not provide the fast response time that is required.

Customizing apps for Industrial IoT

Most solution integrators are not familiar with the various fieldbus protocols used by field devices in industrial automation. They typically end up deploying standard data management solutions that can cater well to IT applications but cannot support the data-acquisition, storage, processing, transmission, and data-analytic needs of industrial automation solutions.

Furthermore, the solution integrators might not have the necessary skills to customize these data management solutions for the needs of the Industrial IoT. A customized solution that can fill the gap between the IT and IA applications is required. IT experts, who are oriented more towards the needs of business applications, need to be trained on the critical requirements of industrial applications so that they can build data solutions that are a good fit for Industrial IoT solutions.

Customized Industrial IoT solutions

It is common knowledge that any customization of controllers, data loggers, and routers requires huge investments of time and money. Embedded computers are highly customizable, but you have to build what you need from scratch.

An intermediate solution that combines the capabilities of a controller, data logger, router, and customized software will significantly shorten the time-to-market. Such a ready-made solution will allow you to focus on your core competencies rather than build a customized solution.

Easy-to-use GUI for data acquisition

A configurable easy-to-use GUI (graphical user interface) for data acquisition, which allows an IT expert to handle the popular Modbus protocols in industrial automation applications without the need for any additional programming will take the pressure off of the field engineers who can focus on the tasks that they are good at.

Modern solutions combine the capabilities of a pure computing platform coupled with a data logger and LTE router.

Seamless integration of data

Edge devices are deployed and used every day to fill the information gap in the field. These devices operate based on different Modbus protocols or may sometimes use proprietary protocols. The deployment of these edge devices is widening the boundaries of a traditional enterprise into spaces that were never before imagined. Centralized data management systems must be able to integrate disparate data types from these devices and add the relevant contextual dimension to the data to create a unified view of the operations for effective system management.

The volume of data that is generated by the edge devices is growing exponentially. Industrial IoT solutions must include a strategy to handle such large volumes of data. Industrial IoT applications should have the built-in ability to respond locally to a field alert and take corrective action at the device end to enable faster response time instead of transmitting data to a centralized data management system. The process of transmitting data to a centralized system for processing could take up to a few minutes, which could be too late if it involves data relating to critical industrial processes.

Local intelligence & edge computing

One strategy to achieve faster response time is to deploy Big Data solutions, which are expensive and require skilled personnel. Alternatively, you can process data locally either in the IoT gateway or at the device-end and make decisions locally, which is much faster. Then, only critical data needs to be sent to the central system after data is processed locally. Solutions that support such local intelligence will also help in reducing the data load on an industrial network.

On-demand communication

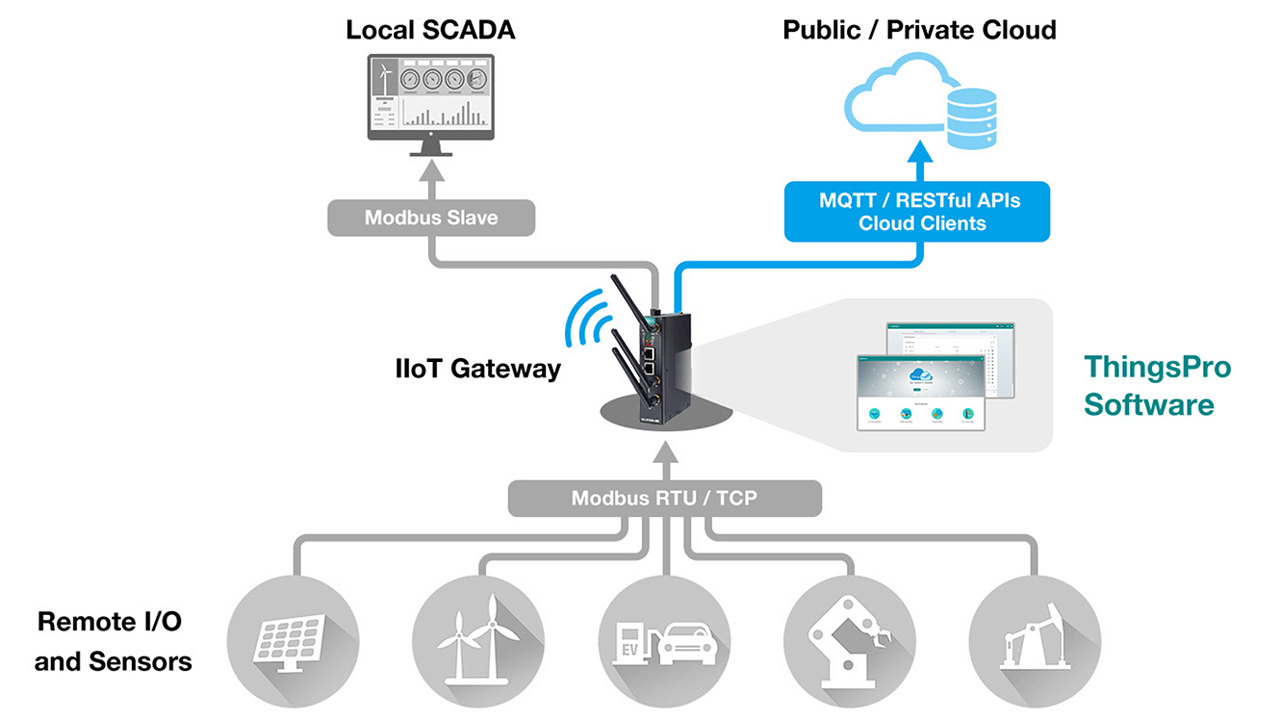

An Industrial IoT Gateway is a critical component of an effective Industrial IoT solution. The gateway is used to mass-deploy devices at the field site, acquire data from these devices, and route this data on demand to the central system, to other devices, or to a remote site. However, the complexity of routing heterogeneous data in a network and the stability of the network link might hinder the progress of your solution deployment, and create bottlenecks for remote data transmission.

An IoT solution that can simplify data acquisition from devices that use the most popular Modbus protocols and route this data using built-in 4G LTE communication capability will enable efficient, on-demand transmission of data, and faster response times.

Developing future-proof solutions

Keeping in mind how rapidly the Industrial IoT field is changing, a scalable solution that can adopt and implement a new technology will give you good returns on your investment. For example, if your service provider decides to upgrade to a newer technology like 4G LTE, substantial changes in your network infrastructure might be required to maintain basic connectivity. Older communication standards such as 3G may no longer be supported and you will have to upgrade to the new technology.

As more and more service providers jump on the 4G LTE bandwagon, the sooner you adopt this new technology the better off your business will be. Rather than wait for the change, a better solution would be to proactively seek out systems and solutions that are future-proof or require minimum change to adopt or support newer technology.

Embracing new technologies has the potential to provide substantial gains and make your system work in more efficient ways than you might otherwise have imagined. Your Industrial IoT solutions can benefit immensely from the following new features:

- Built-in packet routing and logging service for wireless networks

- LTE management support for smooth deployment and higher maintainability of devices

- MQTT support for machine-to-machine communication and to enable remote devices to communicate directly with the cloud

- RESTful APIs for data integration with other systems

Meeting challenges head-on

To understand the changing landscape of the Industrial IoT world, let us consider the example of a power utility provider. To maintain the stability of a power grid, the provider must often isolate or cut off connections with the sections of the network where a surge or an abnormality is detected.

This means that the sensor deployed at the location will detect an issue and then use the WAN to send an alarm notification to the centralized SCADA system, which in turn sends a signal to the circuit breaker in the affected area to isolate the section of the transmission network.

This entire process could take up to 30 seconds, which is too slow in the case of a power transmission grid. To prevent the situation from getting out of hand, the problem area must be isolated immediately. Local intelligence in the edge device, in this case the sensor, is very critical so that a signal to trip the circuit breaker when a problem is detected can be processed and sent immediately from the sensor itself.

This case illustrates a clear need for an intelligent IoT gateway or an intelligent edge device for faster decision making. A centralized architecture where the data is sent to the SCADA system for processing does not provide the fast response time that is required.

The power utility provider is also responsible for providing backup power to the consumers affected by a power outage. This means that a change in the state of the power transmission system should immediately trigger the backup generator located at the consumer’s site to kick in and provide backup power. Once the situation is rectified, the sensor deployed at the backup generator should sense the change in status and switch the power supply back to the grid. This complete solution can be easily implemented using an Industrial IoT system consisting of an Industrial IoT gateway and sensing devices.

IIoT gateway software solutions

IT experts who have limited knowledge of industrial automation can use advanced software to master data-oriented Industrial IoT applications. Moxa’s ThingsPro software technology provides a platform that eases IIoT deployments, so that system integrators can focus on their core competency to deliver solutions and services faster with minimum effort. IIoT gateway solutions can offer:

- Easy-to-use configurable GUI for data acquisition with the most popular Modbus protocols and with LTE-enabled routing capability

- Future-proof technologies for local intelligence

- MQTT support for a lightweight, asynchronous data exchange protocol in heterogeneous applications

- RESTful APIs for gateway configuration that take advantage of HTTP methodologies provide application flexibility and insight into IIoT gateway.

By providing a solution that combines the capabilities of the computing platform coupled with a data logger and LTE router, advanced software can save valuable setup time. The technology does this by handling the Modbus data acquisition and wireless management requirements, especially LTE, while at the same time providing with the flexibility to program applications and extend the capabilities of the IIoT gateway.