TechnologyMarch 22, 2024

Converged IT-OT networks using Time-Sensitive Networking

Machine control networking is built on consistent data delivery of data between controllers, sensors and actuators. TSN is one way to ensure that deterministic control information can be prioritized and delivered on-time while simultaneously allowing non-critical forms of application data to coexist on the same network.

TIME-SENSITIVE NETWORKING (TSN) FOR MANUFACTURING APPLICATIONS continues to move ahead driven by use of Gigabit Ethernet and converged network architectures that combine deterministic control information and application data on the same network.

In this special report, the Industrial Ethernet Book reached out to industry experts to gain their insights into the megatrends driving adoption of Time-Sensitive Networking (TSN), and how the technology is evolving.

“The main benefit of TSN is the converged network which enables fieldbus and IT functions without interfering with each other. The advantages of the converged network can be used in any application and industry. However, this requires 1Gbps bandwidth or more.” — Gunnar Lessmann, Master Specialist Profinet and TSN for PLCnext Technology, Business Area Industry Management and Automation.

Converged Ethernet networks

Gigabit performance provides bandwidth required for real-time communication.

According to Gunnar Lessmann, Master Specialist Profinet and TSN for PLCnext Technology, Business Area Industry Management and Automation, “the main benefit of TSN is the converged network which enables fieldbus and IT functions without interfering with each other. This is especially relevant in applications with high bandwidth requirements, such as data from vision cameras in combination with real-time data. The advantages of the converged network can be used in any application and industry. However, this requires 1Gbps bandwidth or more.”

“The adoption of Gigabit and even higher link-speeds in switches, cameras, and PCs has largely occurred. For field devices and some PLCs, especially with integrated switches, Gigabit is not yet very common. Therefore, the benefit of a converged network with those components are limited,” Lessmann said.

“In contrast to the ‘fieldbus world’, in a convergent Gigabit network, the greatest bandwidth requirement is not generated by the OT but by the IT devices. For example, a GigE Vision camera generates more than 1Gbit network load, depending on the resolution and update frequency (Frames per Second). This must be possible in a network convergent with real-time communication and without mutual influence. Therefore, market adoption to gigabit in every field device is needed,” he added.

Highly accurate timestamps

Beside the converged network, Lessmann said that another advantageous use case of TSN is the ability to provide device data with highly accurate timestamps. This feature is very helpful for data analytics applications, e.g., “in the cloud”. Typical data analytics tools are using time stamps to correlate the data from the field. Without TSN standards like PTP, this is not yet possible.

In addition to the converged network and data analytics, he added tht a major advantage of TSN is the use of standard Ethernet implementations in the devices without special fieldbus-specific chips. However, the chip industry still must learn here. For this reason, Phoenix Contact, together with other partners, has initiated an open-source testing tool for chip manufacturers.

With this tool, it is possible to validate TSN-capable hardware independently of ecosystems such as PROFINET or OPC UA. It is available at https://github.com/Linutronix/TSN-Testbench.

TSN in manufacturing

“It is important to understand that the converged network is already usable today. Some TSN standard, such as Pre-Emption and Quality-Of-Service make this possible,” Lessmann said. “Systems such as Profinet already use QoS and can be used in a convergent network together with other IT traffic.”

“If the application does not have any further requirements, such as time synchronization or isochronous operation, there is nothing wrong with using it. There’s no need to wait. The only thing that is needed for this are gigabit components with QoS and Pre-Emption and the ability to synchronize time via PTP.”

Lessmann added that additional features may be added in future upgrades. Thanks to the common hardware platform, this is also possible independently of “ecosystems” such as OPC UA or PROFINET. Especially with PROFINET, existing 100-bit devices can also be seamlessly integrated.

Anticipated impact of TSN

Lessmann said that, “when we take a closer look at today’s machine and plant designs, we find that several Ethernet and Fieldbus systems with special properties are used for special applications. A network for motion control, a network for cameras, a network for Windows PCs, etc. The associated costs in installation, commissioning and maintenance are directly comprehensible through the switch to a converged network.”

“We expect that in the 3–5-year period, the specialized communication systems will be replaced by the converged TSN network. There’s no need to wait either. In particular, the switches must meet the necessary requirements for the converged network. This is already the case today,” he said.

“TSN provides capabilities to synchronize devices of all kinds and manage multiple classes of data traffic including critical real-time data, non-deterministic burst traffic, and various kinds of diagnostic and best-effort traffic. Precise control over data delivery times is crucial in factory automation, with some kinds of applications requiring sub-millisecond cycle times across multiple I/O elements,” Georg Stöger, Director Consulting, TTTech Dependable Networks.

Integrated system architectures

Higher data rates, increased flexibility and efficiency.

“At TTTech, we observe that TSN customers typically show interest in transitioning from conventional machine network architectures to more integrated systems, often looking to upgrade to higher data rates to be able to build larger machines and gain increased flexibility and efficiency while keeping the performance of existing fieldbus-based network architectures,” Georg Stöger, Director Consulting, TTTech Dependable Networks, told the Industrial Ethernet Book recently.

“Additionally, there’s a noticeable trend among customers to integrate more functions into core machine networks. Obstacles to widespread TSN adoption that we observe are related to costs of upgrading existing infrastructures, specifically if more CPU power is needed to manage the upgraded network interfaces, and the lack of TSN ASICs for some use cases. Outside of machines, TSN adoption in factory automation faces challenges because the current technologies in use are firmly established, and the dominance of existing network systems creates hurdles for the smooth integration of TSN. Companies are hesitant to switch due to investments in and existing competencies with the current technologies.”

TSN technology benefits

According to Stöger, TSN provides capabilities to synchronize devices of all kinds and manage multiple classes of data traffic including critical real-time data, non-deterministic burst traffic, and various kinds of diagnostic and best-effort traffic. Precise control over data delivery times is crucial in factory automation, with some kinds of applications requiring sub-millisecond cycle times across multiple I/O elements. Before TSN, this kind of performance was only achievable with specialized fieldbus technologies, which could not provide the openness, compatibility, and scalability of standard Ethernet.

“The convergence of multiple functionalities onto a unified network infrastructure that is made possible with TSN helps to reduce complexity and can also improve overall system performance and optimization, for example by removing the need for dedicated gateways,” Stöger said.

“TSN networks can utilize a combination of general purpose and automation-specific Ethernet physical layer technologies and a wide range of different bitrates, from cheap 10 Mbit per second to high-performance 10 Gbps backbones. This makes TSN uniquely flexible and adaptable to different kinds of complex network architectures.”

Stöger added that time-sensitive networking also provides wide compatibility with open ecosystems, ensuring interoperability across diverse devices and vendors. This openness specifically facilitates the integration of the OPC UA for Fieldbus Exchange (OPC UA FX), which covers an extremely wide range of applications from very low latency on the field level to controller-to-controller communication and edge-cloud communication.

Compared to existing solutions, this combination of synchronization and deterministic communication capabilities, the commitment to standardized protocols, and the scalability offered by standard Ethernet networking technologies give TSN a unique edge.

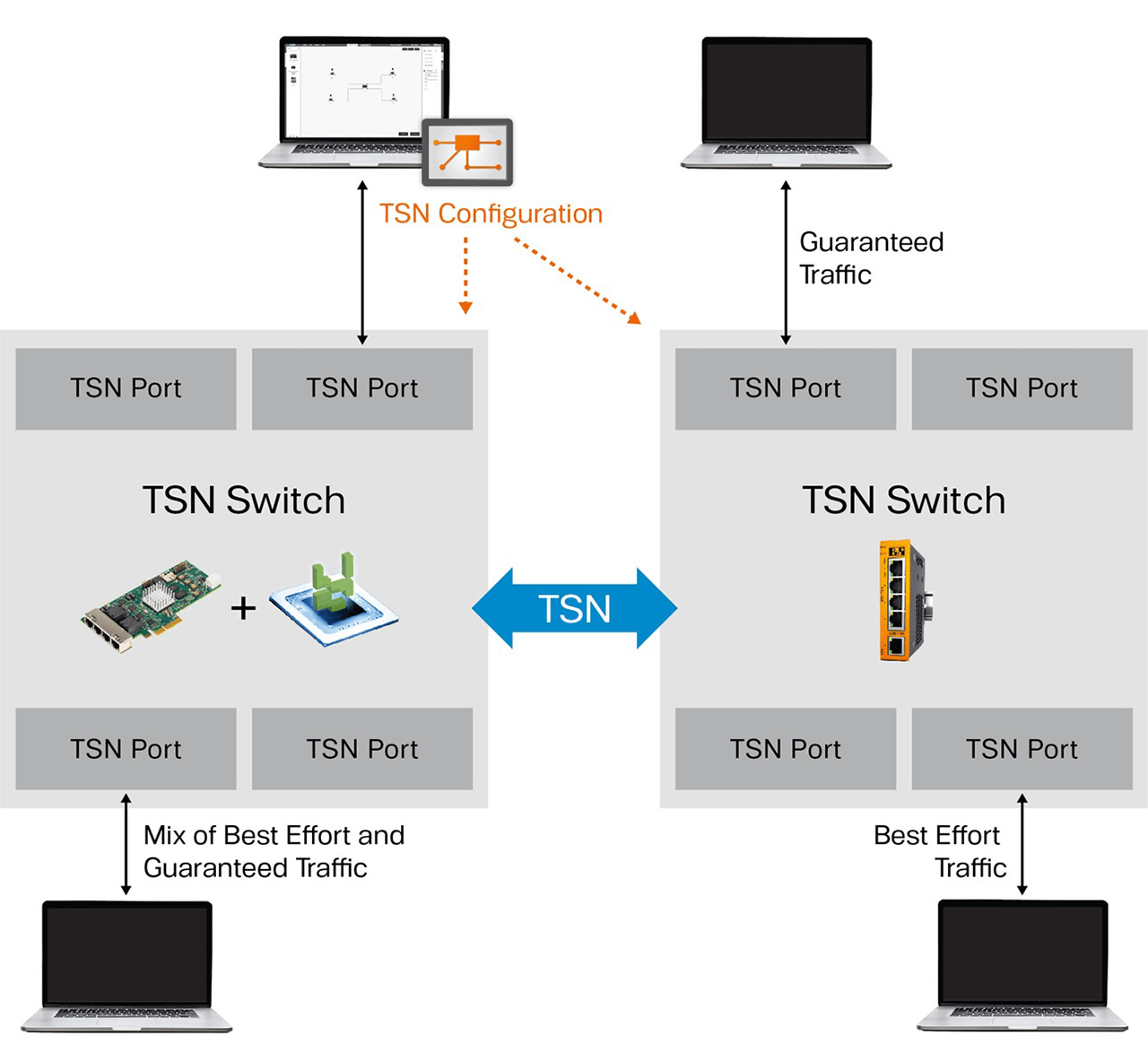

Typical TSN network setup with different switch providers, enabling standard-compliant planning and configuration.

Industry focus

“As one of the first companies to offer TSN technologies, we get requests for TSN from a very wide range of industries, ranging from aerospace and railway to industrial automation and robotics,”. Stöger said. “Applications for which TSN use is considered, investigated, or implemented vary from classic control applications to system-level convergence and the implementation of AI based capabilities such as digital twins at the edge. We do not currently see a pattern which specific TSN capabilities are considered the most transformative when we look across all of the industries we are operating in. However, in manufacturing, the real-time capabilities of TSN combined with the flexibility, openness and scalability in terms of bandwidth and network topologies are the main drivers for customer interest. And OPC UA is becoming more relevant as well, which gives TSN an additional push via OPC UA FX.

Stöger said that, in conclusion, the determinism, support for higher data rates, flexibility, and commitment to open standards collectively drive customers to embrace TSN as a transformative technology in manufacturing applications.

AI-based applications

“We expect to see continued proliferation of AI-based applications and the evolution of edge-cloud interaction specifically driven by federated AI applications. TSN’s deterministic communication will play a pivotal role in optimizing the synchronization of AI algorithms and data flows, enabling real-time decision-making in smart manufacturing processes. The integration of TSN with federated data acquisition for AI applications can e.g. enhance predictive maintenance, quality control, and overall operational efficiency,” Stöger said.

TSN’s support for higher data rates will facilitate better interaction between edge devices and cloud-based systems. More bidirectional communication between edge and cloud will enable the efficient exchange of data for analysis and near-real-time optimization, supporting more sophisticated and data-driven decision-making at both the edge and cloud levels.

“As smart manufacturing continues to evolve, we expect the confluence of TSN technology with AI applications and the refinement of edge-cloud interactions to provide the basis for a more responsive, intelligent, and interconnected manufacturing ecosystem in the coming years,” Stöger concluded.

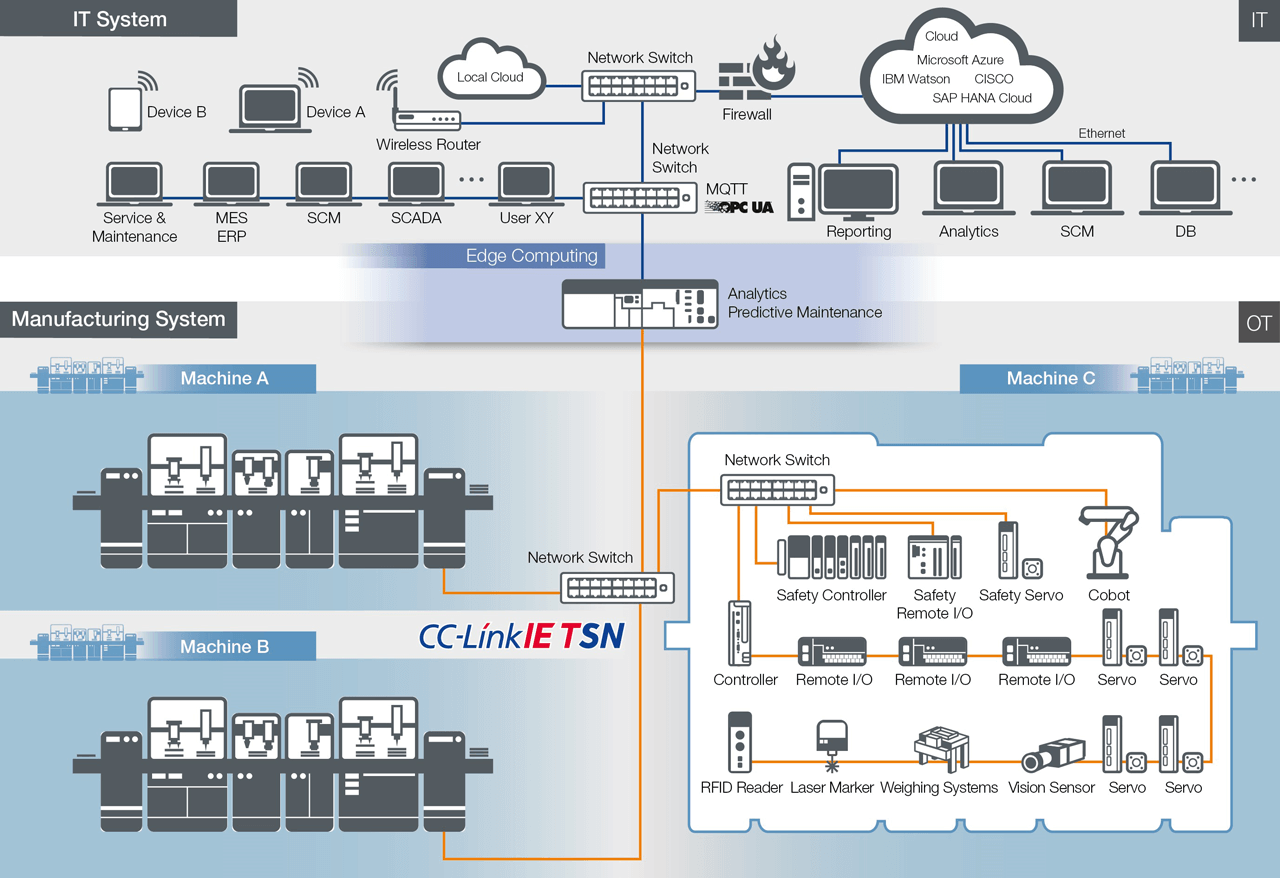

“TSN is an example of how the boundaries between the operational and information technology worlds are overlapping and hence this means the traditional shop floor electrician skills now also need to be supplemented by some skills from the IT sector for successful implementation and operation,” John Browett, General Manager, CC-Link Partner Association Europe.

Overlapping boundaries between IT and OT

Converged network architectures offer integrated solutions.

The marketplace adoption of Time-Sensitive Networking in factory automation applications, and the types of customers moving to adopt, along with obstacles and challenges to larger scale adoption, have become key issues for TSN.

“We are seeing large scale adoption of TSN in various end user applications. We have seen over 100 global companies in a wide variety of industries implement TSN systems in their applications,” John Browett, General Manager, CC-Link Partner Association Europe, told the Industrial Ethernet Book recently. “These industries cover a diverse range such as consumer packaged goods, logistics, consumer electronics, automotive, semiconductor, food & beverage and lithium batteries.”

According to Browett, the potential obstacles to adoption currently may include some of the adverse economic effects that we are currently seeing in some parts of the world that may be impacting plans for capital investment in various industries. In some cases, employee skill sets may also have an effect.

“TSN is an example of how the boundaries between the operational and information technology worlds are overlapping and hence this means the traditional shop floor electrician skills now also need to be supplemented by some skills from the IT sector for successful implementation and operation. However, based on the uptake we outlined above, it’s clear that many companies have already successfully addressed these issues,” Browett said.

Focus on innovation

Specific technology innovations are providing the upside for use of TSN in the factory, and TSN technology does provide unique benefits compared to existing solutions.

“The key benefit that TSN is providing that no technology before successfully addressed is converged network architectures,” Browett said. “In the past, multiple discrete networks were needed to handle different types of communication. So perhaps there was one network for I/O, another for motion control, a third for functional safety and then finally perhaps a general IT oriented network for handling communication with higher level systems.”

With the advent of TSN and its converged network capabilities, the technology now offers an ability to move away from this scenario.

“We are in a position where previously multiple networks were required to implement an application, these can now be combined into a single architecture. In turn, this will deliver a number of benefits such as simpler designs, reduced costs, easier maintenance and greater uptime,” Browett added. “This translates to projects that can be implemented more quickly, processes that can be operated more efficiently and ultimately business that can deliver more value.”

He added that there are specific industries, types of applications and types of customers, where TSN is gaining a foothold in the marketplace.

“We have seen a number of cases where the highly deterministic performance capabilities enabled by TSN help deliver sophisticated motion control applications,” Browett said. “These applications are in industries whose processes typically include large numbers of motion control axes whose operations are precisely synchronized in order to deliver the required levels of product quality and productivity. The industries concerned have typically been lithium battery and printing.”

In lithium battery manufacturing, for example, various motion intensive tasks are required, such as coating, winding and general product handling. These are highly demanding critical processes, which if performed incorrectly may lead to products which fall below the required performance standards, or may even be unsafe in extreme cases. Moreover, the high performance achieved by TSN based systems allows the ambitious productivity goals of the automotive industry to be met.

Printing may seem to be a less demanding application, but the need to meet quality and productivity standards is the same in the end. Printing typically requires the application of multiple colors and finishes on a product that may range from documents to containers such as bottles. Without precise synchronization enabled by deterministic TSN control between multiple axes, meeting the required quality standards is more difficult.

Time-Sensitive Networking converged network architectures provides a range of benefits to end users and machine builders worldwide.

Anticipated impact

Browett expects that TSN technology will have an impact on smart manufacturing in the next 3-5 years.

“We anticipate that the adoption will continue. We are seeing a high level of interest from the device vendor community in TSN. This means that the catalogue of compatible products will continue to grow as we move forward,” he said. “We are also seeing industry wide initiatives to continue driving the adoption of TSN. These include IEC/IEEE 60802, which is working on developing profiles for the use of TSN in industrial automation.”

Building on this, TIACC is a further activity that is aimed at standardizing the conformance testing of 60802 devices. This is being supported by the key open industrial automation network organizations, meaning that there will be guaranteed interoperability of TSN compatible devices as we go forwards.

“These activities are being matched by the interest in the end user community, where we continue to see companies in a wide variety of industries recognize the benefits TSN can deliver to their operations. This in turn will drive further demand for devices and systems that can provide these benefits and hence continue to make the demand for TSN based systems increase in the future,” Browett said.

“There has been significant progress on various fronts across the TSN ecosystem, but more can still be done. The IEEE/IEC 60802 TSN profile for industrial automation is currently going through the balloting and comment resolution process. While this is underway, several industrial organizations are already defining the expectations for TSN components and device implementations, as part of the TIACC collaboration,” Dave Cavalcanti, Avnu Alliance President and Chair of the Wireless TSN Working Group.

Looking at the current state of TSN technology

Developments, specifications, challenges and what to expect to see in the future.

Dave Cavalcanti, Avnu Alliance President and Chair of the Wireless TSN Working Group, responded to IEB with his answers to questions and insights on the keys to broadening TSN deployments, developments in the industry and what to expect in the future.

What are the key steps needed for real deployments of TSN?

Real deployments of TSN in large scale applications require many pieces to fit together, much like a puzzle. First, standards need to be developed, with the aim of getting vendors to implement and test products based on the core features required by the market. This is where testing is vital, ensuring the conformity of the implementations with the specification itself. It is essential that device behave in a predictable manner while delivering a consistent, reliable performance, while interoperating in their relevant field.

The development of test specifications and tools, alongside the creation of certification programs, are a key part of the work done by the Avnu Alliance and its members to enable the TSN ecosystem.

Encouraging vendors, developers and users to work together to build, test and enhance their TSN feature implementations is also crucial. This is why our Plugfests are the perfect environment for cross-industry collaborations and co-development. These events result in robust and interoperable products that, when deployed, provide assurance that they will perform and work as expected. All these steps are being facilitated by the Avnu Alliance through its certification programs for standard compliant TSN components and devices.

What developments are we seeing within the industry? What specifications are being focused on presently?

We have seen great progress in the development and publishing of core TSN specifications, including IEEE 802.1AS-2020, 802.1Qbv, 802.1Qbu and more. Recently, the IEEE/IEC 60802 group has also reached a significant milestone by defining the main features and requirements for the TSN profile for industrial automation.

There has also been fantastic collaboration across key industry players to define Avnu Alliance test specifications and tools for a number of TSN standards. Our organization is actively working with several industrial organizations, as part of the TIACC collaboration, to advance the testing specification which covers the requirements in the IEEE/IEC 60802 Industrial TSN profile. With well-defined standards and test specifications for core TSN features, such as time synchronization, traffic shaping and preemption, vendors are being empowered to develop and test their own implementations.

We had a significant number of vendors participate in the latest Avnu Alliance Plugfest, where they’ve had the opportunity to run interoperability and conformance tests using our approved test tools. The next step will be to get TSN-capable devices and components certified through one of our certification programs. The Avnu Alliance will soon be launching a new TSN component certification, and our TSN switch certification program is currently undergoing a renovation to better streamline the process and make it easier for vendors to both submit and certify their products.

Currently, our members are working to extend TSN capabilities across various networks, including Wi-Fi and 5G. We are already seeing good progress being made in terms of implementations and testing of wireless capabilities in both of these networks, and the Avnu Alliance are also working on the extension of our certification programs to include wireless in the near future.

What can we expect to see in the future, and are there still challenges that need addressing?

There has been significant progress on various fronts across the TSN ecosystem, but more can still be done. The IEEE/IEC 60802 TSN profile for industrial automation is currently going through the balloting and comment resolution process. While this is underway, several industrial organizations are already defining the expectations for TSN components and device implementations, as part of the TIACC collaboration.

The Avnu Alliance has already contributed on several TSN test specifications which will create the basis of the necessary test requirements. Understanding the TSN toolbox approach will also play a crucial role in long-term market deployment. There will be additional features and enhancements to TSN standards and implementations that will need to be deployed over a longer period. The extensions of TSN capabilities, such as time synchronization and time-aware shaping to wireless systems (Wi-Fi and 5G), are a good example of what we can expect in the future.

Understanding the system level challenges that come with deploying and configuring TSN-based networks is another area where our members are focusing their efforts at present. We envision networks that are both configurable and autonomous, while meeting hard, real-time requirements. TSN is also expanding across many key segments, including ProAV and Automotive. Driving the concept of fundamental TSN technologies that are agnostic of applications is very important if we are to achieve the economies of scale required for success in these markets.