TechnologyNovember 2, 2022

Carbon emission control through wireless IoT technology

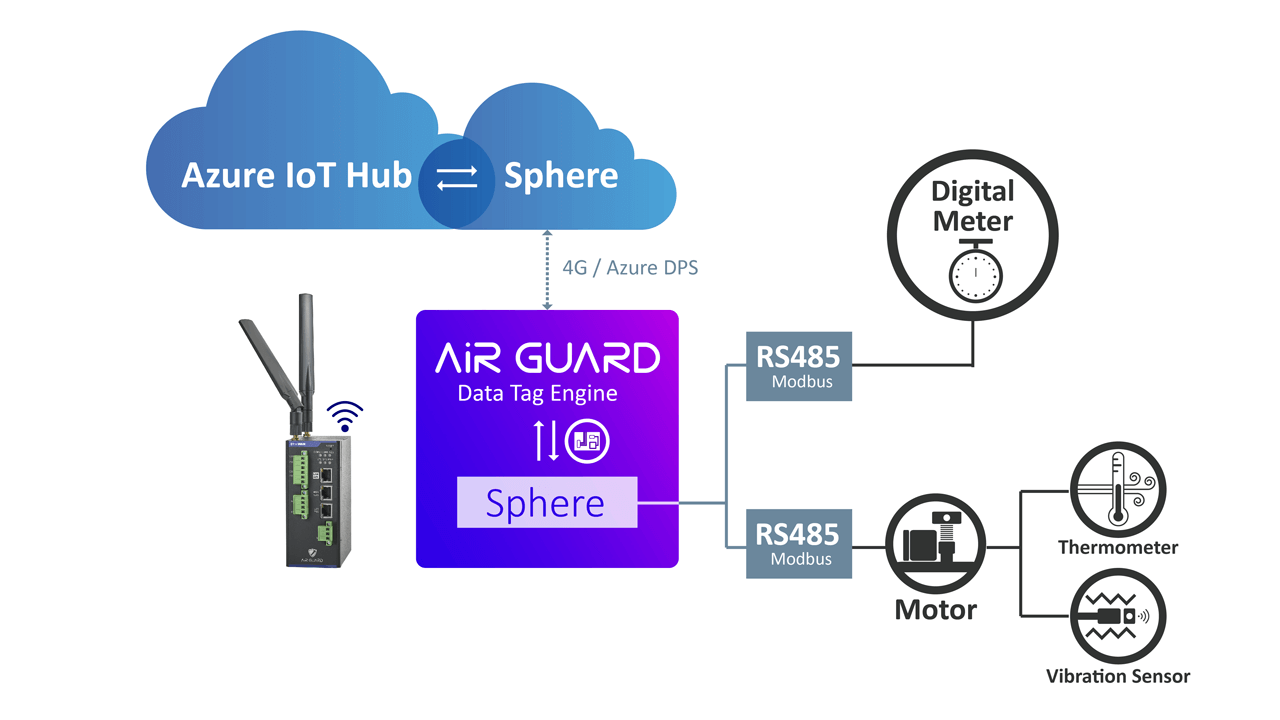

AiR GUARD technology uses a cellular wireless device to enable monitoring and calculation of the carbon dioxide produced by manufacturing processes from field sites. It connects digital meters via Modbus RS-485, and data is transmitted in an encrypted format through the Azure Sphere chipset.

Carbon emissions in the construction phase will gain significance over time. However, a real-time emissions monitoring tool, essential to help construction teams avoid excessive emissions, has not been introduced yet. Therefore, with a focus on enhancing monitoring of carbon emissions in this stage, EtherWAN proposes an IoT-based system framework that integrates a distributed sensor network to collect real-time emissions data.

In manufacturing systems, a process plan is the combination of diverse production processes and operations. Due to the different processes employed, even a small change in product process design can impact the environment in different ways. Additionally, the carbon emissions caused by auxiliary resource and energy consumption mainly stem from the electrical energy consumption of ancillary equipment in manufacturing plants, such as lighting, heating, and ventilation.

Once the quantitative values for each unit process and carbon emissions breakdown are determined, a range of improvement opportunities can be identified to monitor the resource and energy consumption during the entire process planning period. Each improvement opportunity has been linked to a positive effect on at least one previously identified carbon emission. When the factory or energy utility field site in a harsh environment becomes subject to carbon emission control, the next hot topic will be how industrial Ethernet systems take the CFV (Carbon Footprint Verification).

EtherWAN’s AiR GUARD is a cellular wireless device that enables the monitoring and calculation of the carbon dioxide produced by manufacturing processes from field sites through its specialized system. Furthermore, AiR GUARD connects the digital meters in the distribution board via the AiR GUARD Modbus RS-485. The data is transmitted in encrypted format through the Azure Sphere chipset. Then the received data from the AiR GUARD DPS will be sent to and stored in the AI system for analysis and calculation. All the analyzed outcomes will represent the data of the Carbon Footprint. The whole system can subsequently run the CFV management and control.

AiR GUARD plays an important role in this smarCFV system. It is a gateway that offers highly-reliable network connection through global 4G LTE, as well as operation at temperatures ranging from -40 to 75°C. AiR GUARD supports the MQTT protocol and OpenVPN, and is also equipped with the Microsoft Azure Sphere chipset, allowing for the combination of Azure cloud and cybersecurity protection. With its wireless features and combination with Azure Cloud tech, the entire CFV process can be easily set up without complex cabling and storage devices. In addition, the security and maintenance of network transmission can also be taken into consideration.

To avoid the worst climate impacts, global greenhouse gas emissions must be slashed in half during the next decade, and reach net-zero early in the second half of the century. EtherWAN specializes in industrial-grade wired/wireless Ethernet connectivity devices, and is looking forward to its brand and products taking a role in the future drive towards net-zero for large enterprises. EtherWAN is demonstrating to industries worldwide the path to a greener planet.