TechnologyMarch 19, 2023

EtherNet/IP technology and applications update

EtherNet/IP offers a potent industrial automation network solution by relying on commercial-off-the-shelf technology and standard, unmodified Internet Protocol and Ethernet made up of IEEE 802.3 combined with the TCP/IP Suite, to enable seamless, interconnected networks for local, edge and cloud applications.

Factory connectivity solutions have accelerated the transition from fieldbuses to Industrial Ethernet. And now, Single Pair Ethernet offers a new impetus for growth.

For IEB’s update on EtherNet/IPTM technology, the Industrial Ethernet Book reached out to Dr. Al Beydoun, ODVA President and Executive Director to offer his perspective on this key Industrial Ethernet technology.

EtherNet/IP Q&A

What key technical trends are driving the adoption of EtherNet/IP automation, control and networking solutions?

Beydoun: The value of increased connectivity including easier commissioning, troubleshooting, and asset tracking driven by IIoT and Industry 4.0, have accelerated the transition from traditional fieldbus to industrial Ethernet. As companies digitalize in their journey to further optimize operations, EtherNet/IP is seeing sustained strong growth due to being a proven automation solution that is continuously enhanced to address future advancements in industrial control and communication. The ability for end users to now leverage edge and cloud analytics to gain insights into historical trends and make predictions about future device and production status has also increased the value of standardized Ethernet networks with robust safety and security protocols like EtherNet/IP.

EtherNet/IP is a proven industrial control networking solution that can accommodate everything from a single controller, machine, or skid to entire facility installations across discrete, hybrid, and process automation. Diverse industries such as automotive, semiconductor, packaging, food & beverage, pharmaceutical, water and wastewater, chemical, mining, oil & gas, and more rely on EtherNet/IP communication and control. EtherNet/IP utilizes ODVA’s CIPTM application layer and deploys it on standard networking technologies such as Ethernet, Single Pair Ethernet/Ethernet-APL, Wi-Fi, or 5G.

What are the key technical advantages of automation systems that utilize EtherNet/IP technology solutions? What are its primary technology benefits for automation and control networking?

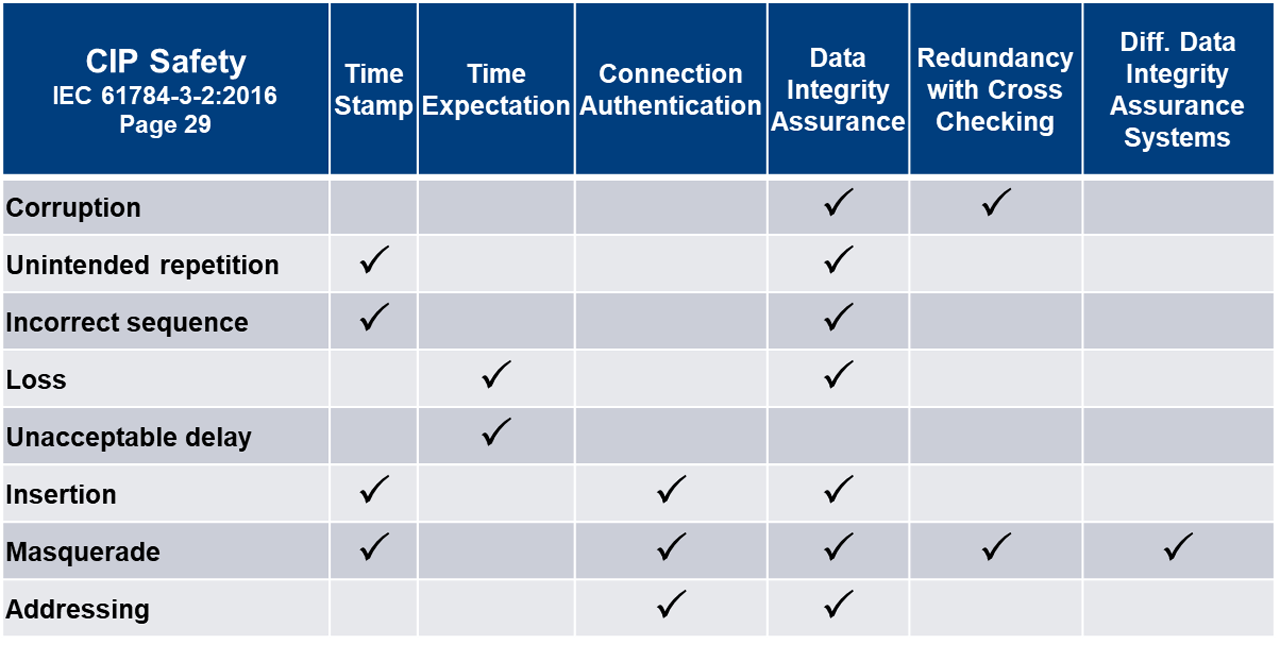

Beydoun: EtherNet/IP has become a leading industrial automation network solution in part by relying on commercial-off-the-shelf technology and standard, unmodified Internet Protocol and Ethernet made up of IEEE 802.3 combined with the TCP/IP Suite, which enables a more seamless, interconnected network for local, edge and cloud applications. Additionally, EtherNet/IP offers a complete suite of network extensions for specialized applications including safety, security, energy, time synchronization, and motion. CIP Security offers a distinct advantage for EtherNet/IP given that it offers the flexibility of different levels of device level security depending on the network performance requirements relative to the sensitivity of the information and potential negative health and safety impacts of the intervention of a bad actor. CIP Security allows for end users to apply one or more protections as desired such as end point authentication, message encryption, user role protection, and more. EtherNet/IP also offers network uptime redundancies that ensure a device failure won’t impact other devices with Device Level Ring (DLR).

Additionally, EtherNet/IP is lightweight enough to be able to work with resource constrained devices such as contactors and push buttons via Single Pair Ethernet (SPE). Finally, EtherNet/IP supports process automation via features such as NAMUR NE 107 device status and Ethernet-APL support for long reach and intrinsically safe applications.

What is the impact of SPE and/or Ethernet-APL technologies on the types of EtherNet/IP network architectures that are possible? What are the advantages of these new approaches?

Beydoun: As a media independent network, EtherNet/IP is well positioned to take advantage of the benefits of Single Pair Ethernet (SPE) since it is just another physical layer. SPE allows for cost and size reductions in Ethernet PHYs, cable and connectors that enables cost effective connectivity for smaller devices as well as more efficient long cable runs. This opens up the possibility to connect simple devices to Ethernet that were previously only hardwired or controlled via fieldbus technology.

SPE also reduces the overall labor for panel installations and provides information for concepts such as prognostics. ODVA’s in-cabinet resource-constrained device solution is a case in point as it enables contactors and push buttons to be connected to EtherNet/IP via a SPE multidrop flat cable.

It’s important to note that SPE encompasses 10BASE-T1L General Purpose SPE applications, 10BASE-T1S in-cabinet applications, and 10BASE-T1L Ethernet-APL applications. Furthermore, there are multiple IEEE SPE standards in addition those mentioned here, such 100BASE-T1 for automotive applications.

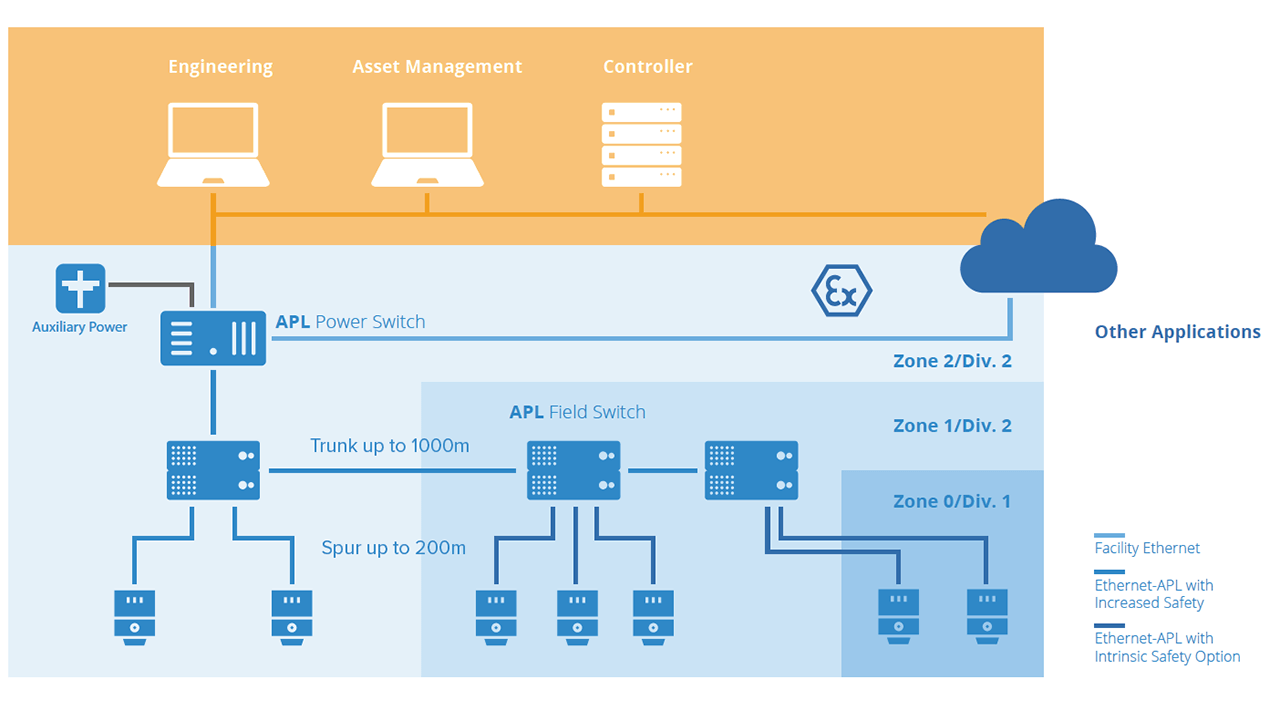

Ethernet-APL meets the ruggedness, simplicity, and security expected by the process industries for a control network. The Trunk and Spur topologies are familiar to end users and Ethernet-APL allows up to 1,000-meter trunk lengths and 200-meter spur lengths.

Ethernet-APL leverages the same Type A fieldbus cable that is currently installed in process plants today. In fact, existing Type A cable may be reused if the cable integrity is verified and resistance standards of 100 ohms with +/- 20 ohms tolerances are met. Since it is just a physical layer, Ethernet-APL allows end users to access standard safety and security services built on IEC 61508 and ISA/IEC 62443 from the leading industrial automation standards bodies. This includes CIP SafetyTM and CIP SecurityTM capabilities for EtherNet/IP. EtherNet/IP is able to expand precise, efficient Ethernet-based control and commissioning across process field instrumentation via the Ethernet-APL physical layer. The full use of EtherNet/IP in process automation enables concurrent seamless connectivity from the field devices to the controllers, to Industrial IoT applications, as well as the edge and cloud for prognostic analysis.

What are specific application areas that the newest EtherNet/IP solutions targeting? How are these solutions contributing to IoT and enterprise connectivity?

Beydoun: The newest application areas that EtherNet/IP solutions are targeting include flexible assembly lines enabled by wireless AGVs, long cable runs in warehouses and in-cabinet wiring using Single Pair Ethernet (SPE), and the addition of different types of traffic to OT networks such as vision and surveillance cameras that can benefit from Time Sensitive Networking (TSN). EtherNet/IP is network technology independent as a result of using CIP at the application layer. This allows for wireless support via Wi-Fi, 5G, and Bluetooth among other technologies that can power AGVs, end of arm tooling for robots, and other mobile devices in a plant. Wireless support for Private 5G has recently been proven in a joint test bed with Rockwell Automation, Ericsson, Qualcomm, and Verizon. Additionally, CIP Safety can be run over wireless due to relying on the black channel principle that leverages data validation techniques built into the network extension.

The media independence of EtherNet/IP also contributes to support for IEEE 10BASE-T1L/T1S SPE, which is growing in importance due to enabling the benefits of Ethernet connectivity at a low cost to devices such as in cabinet contactors and push buttons, discrete RFID sensors, and process temperature, level, and flow sensors. SPE is also capable of long cable runs of up to 1,000 meters for large plants such as package sorting facilities and chemical refineries.

CIP Safety Functionality and benefits.

60802 TSN will make it possible to add new devices to existing networks years after initial commissioning and to include new types of devices on OT networks such as cameras for machine vision and surveillance without significantly degrading network reliability. Once the IEC/IEEE 60802 standard is published, a new Common Industrial Profile (CIP) Application Profile will be released to make 60802-enabled TSN an option for new EtherNet/IP devices either natively or via a gateway. Existing EtherNet/IP devices can also work on TSN networks, although their Quality of Service on the wire may be degraded when compared to a non-TSN network. 60802 TSN will be able to align with CIP Motion via a motion control planner using a common notion of time. Once CIP Motion and IEC/IEEE 60802 are aligned, network transport can be facilitated using scheduling as necessary to meet the needs of the network and coexist fairly with existing traffic. EtherNet/IP is anticipated to have an 60802 TSN compatible specification available as soon as is practical after the IEC/IEEE 60802 TSN specification is released.

What are the engineering challenges that the newest EtherNet/IP systems and architectures are designed to address, and how is EtherNet/IP evolving to provide more comprehensive solutions?

Beydoun: EtherNet/IP systems and architectures are now able to offer Ethernet-APL devices, which unlocks the advantages of commercially based industrial control hardware, an object-oriented foundation, and standard internet protocol compatibility including TCP/IP, HTTP, FTP, SNMP, and DHCP within the process industries.

ODVA is also continuing to expand the EtherNet/IP ecosystem with the next generation of digitized device description files, including FDT, FDI, and xDS, to simplify integration into asset management tools. The end goals of the device description efforts are to provide a standard, robust and detailed description of device information, implement secure device description artifacts, and prepare for a future driven by Industry 4.0 and IIoT.

Furthermore, ODVA supports the PA-DIM process automation device information model specification that can be integrated across communication protocols, meets the requirements of the NAMUR Open Architecture (NOA), and enables end users to better use device data from across the plant.

Future plans include a partnership between ODVA, OPC Foundation, PI, and VDMA to develop a new interface standard for the acquisition of energy consumption data in industrial manufacturing to improve power consumption management. EtherNet/IP also plans to continue to evolve for future requirements by enabling reliable, secure communications between CIP-enabled industrial control system devices and the cloud as well as to enable common cloud gateway and device management tasks. One of the ways this will be accomplished is via a joint working group with the OPC Foundation to develop an OPC UA companion specification to the Common Industrial Protocol (CIP).

Dr. Al Beydoun, President and Executive Director, ODVA