TechnologyJanuary 18, 2024

Evolving the CIP Energy Objects for greater efficiencies

There is a growing movement of energy awareness in all industries and a strong marketing push for better optimization of energy usage in industrial automation. All of the ODVA Energy Objects will need to be updated to reflect the information in a new power consumption management OPC UA specification.

The intention of the CIP Energy™ initiative is to allow for the optimization of energy usage and scalability of implementation from basic energy awareness to advanced functions of energy control including dynamic demand-response. The ODVA Energy Applications SIG originally defined three specific objects, the Base Energy Object, the Electrical Energy Object, and the Non-Electrical Energy Object. Later, the Power Management Object and the Power Curtailment Object were added. These five CIP Objects became the basis for CIP Energy™.

When developed between 2010 and 2015, these objects were state of the art and sufficient for the times. It was discovered during the design of the Power Curtailment Object that revisions were needed for the Power Management Object. A specification enhancement was started but not completed before the ODVA Energy Applications SIG became dormant.

With stronger industry concerns over cost savings in production, energy usage is one of the largest costs and a big concern. It is time to rediscover and modernize the CIP Energy Objects.

This article will discuss the strengths and weaknesses of the current CIP Energy Objects and suggest ways to modernize them, which could include working closely with the OPC Foundation, for today’s industrial operations.

Overview of CIP Energy objects

Energy is an indispensable component of industrial production but has been ineffectively managed as a production resource. Acquiring energy information detailed enough for action has been difficult and costly.

Automation to control energy usage and related costs has likewise been costly, characterized by one-of- a-kind designs, hours of custom engineering effort and difficulty in cost justification. ODVA’s Optimization of Energy Usage (OEU™) comprises a three-tiered approach to increasing the availability of less costly, more granular energy information, and standardizes approaches to the automation of power and energy management.

The three phases of OEU are:

- Awareness of energy usage,

- Consuming energy more efficiently, and

- Procuring energy at the lowest cost.

Between 2010 and 2015, the ODVA Energy Applications Special Interest Group (SIG) published specifications for a family of independent but related CIP Energy Objects to support the OEU strategy and support the addition of energy capabilities to a variety of CIP devices.

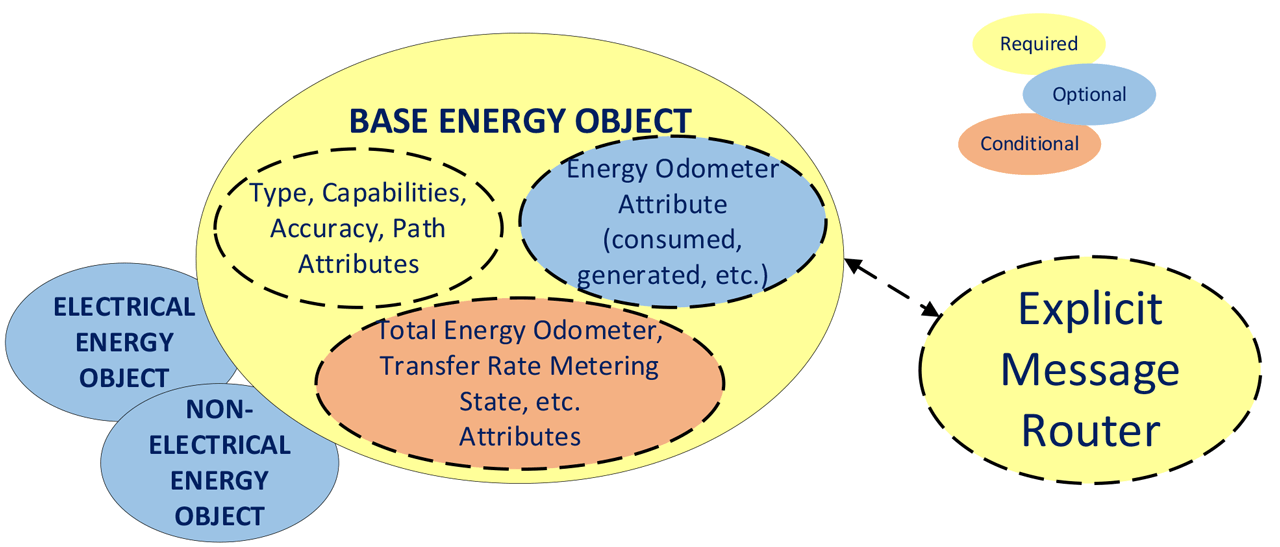

Figure 1: Relationship between the Base Energy Object and the Electrical and Non-Electrical Objects.

Awareness of energy usage

Three related object specifications comprise the energy awareness suite of ODVA energy capabilities.

The Base Energy Object lets devices from simple to complex report their energy usage in a standardized way, in units of kilowatt-hours (kWh). This native electrical energy unit was selected because many ODVA members are electrical device vendors. The Global Reporting Institute (GRI) specifies units of gigajoules (GJ) for energy reporting; however, values in kWh may be easily converted to values in GJ by multiplying by 0.0036. This object also reports accuracy and information on how the data is generated. The Base Energy Object can also be used to report the aggregated usage of a collection of devices, and can act as a proxy, reporting energy usage for devices that cannot do so themselves, or can but are not CIP devices.

The Electrical Energy Object reports a variety of electrical measurements, including voltages, currents, complex power and energy, power factor, frequency, etc., similar to the types of parameters you would find in a high-end meter or power monitor.

The Non-Electrical Energy Object reports usage of energy resources such as natural gas, steam, fuel oil, hot water and chilled water, each in their native energy units (for example, therms, pounds, gallons, Btus, joules, etc.).

Some devices may report very accurate energy data, but high accuracy is not really needed at the device level. There will usually be revenue-accurate meters upstream in the energy distribution network. The energy awareness objects are intended to cost-effectively fill in missing pieces of the energy usage picture where today little or no information exists. This more complete energy picture provides valuable information on the energy behavior of a machine, zone, line, or area, allowing users to make decisions that result in reduced energy usage and cost.

One or more Electrical Energy or Non-Electrical Energy Object instances are associated with an instance of the Base Energy Object. A Base Energy Object instance can report the aggregated usage of a collection of similar Non-Electrical Energy Object instances (“similar” means the instances report usage of the same energy resource in the same units) and/or Electrical Energy instances. It then reports the aggregated usage in kWh in its own instance attributes, and in the native non-electrical energy units in an associated instance of the Non-Electrical Energy Object.

That way, the user can get a single view of all of the energy being used in multiple devices and subsystems in the base units (kWh) while also being able to monitor the non-electrical loads in the units that make sense for those types of devices and subsystems.

Together, this collection of energy objects provides a standardized way to obtain detailed energy usage information in an industrial setting at very low cost. This can help users apply a more direct relationship between products and the energy utilized to manufacture them.

Consuming energy more efficiently

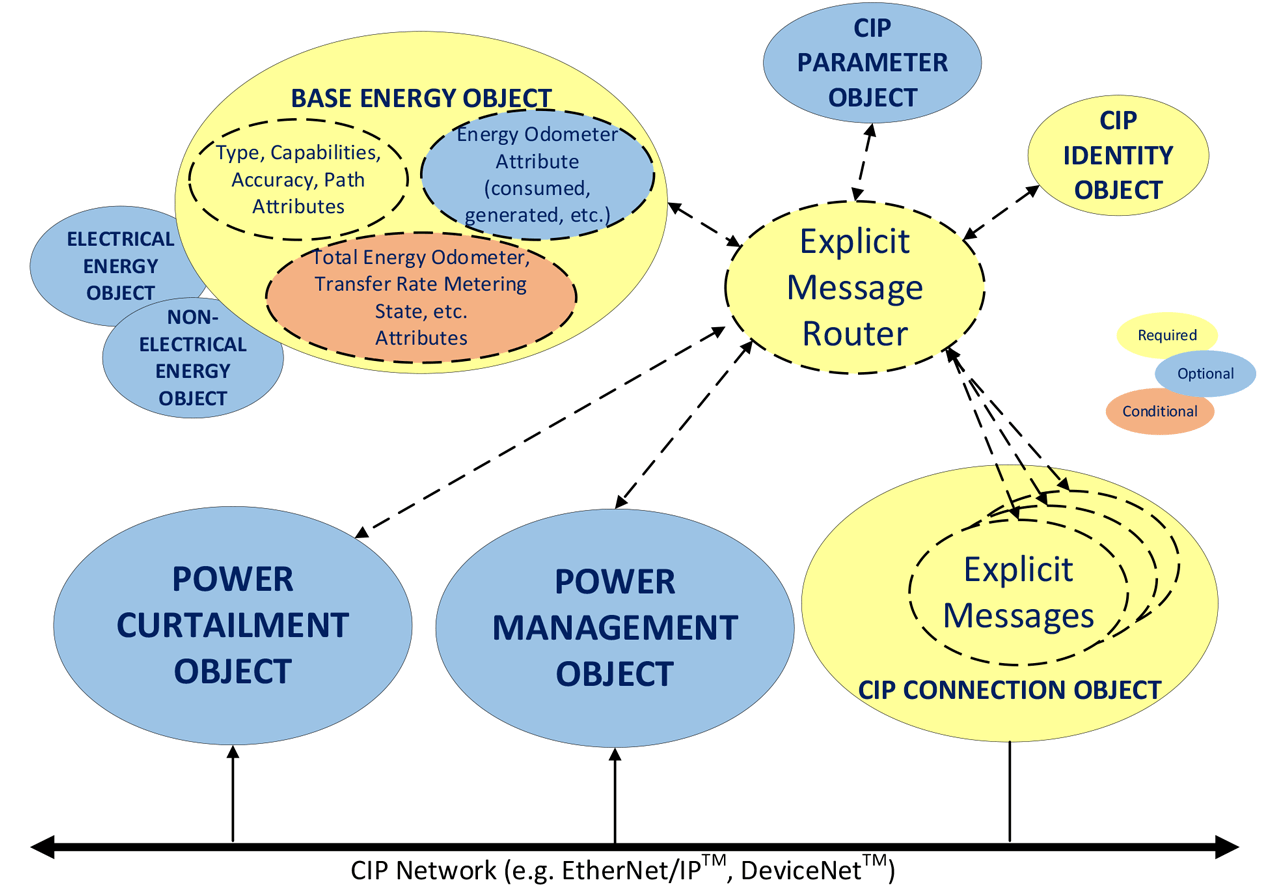

The Power Management Object provides a simple, standardized interface for commanding devices, machines, work cells, and production lines into low-power modes at lunch time, shift changes, weekends, when a bottleneck or breakdown occurs, or during other significant idle periods.

A controller or software application requests a pause expected to last for a specified time. In response, the device reduces the power it uses by going to a predefined pause mode, and letting the application know how much notice to give so the device will be ready when needed. Based on the requested pause time, a device selects a pause mode that saves the most energy possible for the duration and condition of the device. The lowest power level is the “sleeping” mode, where it effectively shuts down except for just enough communications hardware capability to listen for a wake-up call.

Where the Power Management Object saves energy during idle periods, the Power Curtailment Object helps to save energy and avoid demand peaks while production continues at a lower rate of energy consumption. The Power Curtailment Object uses predefined curtailment levels to reduce power.

Curtailment levels are similar in function to pause modes, except the energy managing application requests a desired power level instead of the duration of a pause.

Both the Power Management and Power Curtailment objects act as servers to an energy management client application. The client, which may in turn be a server itself to another higher-level energy management client application, needs to maintain awareness of the big-picture operational environment to manage the energy behavior of its owned devices using services defined in the object specifications. CIP Network (e.g. EtherNet/IPTM, DeviceNetTM).

Both the Power Management and Power Curtailment objects provide a cascade capability, allowing child objects to be controlled by the parent, simplifying the interface to a controlling energy client.

Figure 2: Relationship between the Power Objects and the Energy Objects.

Improvements for better energy management

Changes are needed in the CIP Energy™ Objects for better utilization and execution in products and systems. Some of the proposed changes are simple and quick to implement. The majority of the changes will require more work and possibly some form of prototyping before release.

The easiest and simplest changes to consider are to align the naming convention of the various objects. The Base, Electrical, and Non-Electrical Energy Objects all use “Energy” in the title and descriptions, while the Power Management Object and the Power Curtailment Object use “Power” in their titles and descriptions. To maintain consistent naming and to prevent confusion for the users and developers, the Power Management Object could be renamed the Energy Management Object and the Power Curtailment Object could be renamed the Energy Curtailment Object. A question may be raised if the power objects manage power or energy. Power is amount of work done over a time period (P=W/t).

Where, energy is power multiplied by time (E=Pt). It can be argued that the objects manage both power and energy, so energy in the titles would be fitting.

The CIP Energy objects defined an Odometer data type for tracking energy data. This data type consists of multiple elements, each with a range from 0 to 999. While this data type makes sense for visual display purposes, it is an inefficient data type for internally managing energy data. A 64-bit signed or unsigned integer would be a better choice. Additionally, the rollover behavior of the signed odometer data type does not follow typical rollover behavior of native signed integer types, returning to zero instead of the max positive or negative number.

During the development of the Power Curtailment object, several similar services or properties defined in the Power Management object were enhanced or revised. As a result, the ODVA Energy Applications SIG drafted a Specification Enhancement (CIPSE) CIPSE 0243 008 that was started in May 2014. This CIPSE went through an initial review from several SIG members but was never completed. This CIPSE update was a major rewrite of the Power Management Object.

One of the most powerful features of the Power Management and Power Curtailment objects is the ability to establish parent-child relationships (cascade). This provides the capability for a single parent object, located in, for example, a line controller, to manage or curtail energy in the remaining devices in a system or machine, effectively giving an energy management system a single point of access to the system or machine. This cascading feature was significantly revised during the development of the Power Curtailment object and this enhancement is reflected in in CIPSE 0243 008.

The released energy objects have a reduced set of features. When compared to vendors that have very feature rich metering products, there is functionality in meters that cannot be managed or measured in the current energy objects.

Additional use cases for energy

The working hypothesis for Optimization of Energy Usage Use Cases is as follows:

- Energy is essential to produce products but has been an invisible line item on production bills of materials and consequently an unmanaged resource;

- Energy should be a managed resource in the production domain, and;

- The availability of energy information and visibility of energy consumption will promote awareness by industrial consumers of the need to manage energy as a production resource which, in turn, will lead to best practices in OEU for the industrial consumer.

The additional elements of Optimization of Energy Usage that will be addressed in ongoing work within ODVA are transacting energy for the best results. By leveraging asset management and internal facility and process energy delivery systems, the industrial consumer can interface with the Power Grid domain to procure and exchange energy for the best result. By dynamically and transparently managing demand-response mechanisms, industrial consumers will be able to transact energy to achieve individualized best results based on cost, source, supply, or environmental impact.

Working with OPC Foundation

The Power Consumption Management Group was announced at the Hannover Fair on the 30th of May 2022. This group is a partnership between ODVA, OPC Foundation, Profibus & Profinet International (PI), and Verband Deutscher Maschinen und Anlagenbau (VDMA).

The intention of the group is “to harmonize and standardize energy consumption information on the shop floor”. Al Beydoun, President, and Executive Director of ODVA, states “This Power Consumption Management collaboration will help ensure end users have a highly standardized and interoperable means to reach their environmental, social, and corporate governance (ESG) goals.”. Further, this group is backed by the European Union’s goal to make Europe climate-neutral by 2050 under the “European Green Deal”.

As a result of the partnership, a new specification in the OPC United Architecture (OPC UA) will be written and published.

It will be important that CIP Energy™ and the associated power and energy objects are updated to align with power consumption management OPC UA specification. Since the intended goal of OPC Foundation and ODVA, under the Power Consumption Management Group is ensure standardization of energy information, then updates to the power/energy objects mentioned in this paper must be a priority for ODVA and its member companies.

Market and customer readiness

It is time to restart the Optimization of Energy Usage and the ODVA Energy Applications SIG. There is a strong concern over energy usage throughout sectors of automation, including industrial automation businesses. The best way to address this concern is through better energy management systems.

The market is ready. Market.us estimates the current value of the Global Energy Management System market at 55.2 billion dollars. Further, they estimate that this market will grow to 208.4 billion dollars by 2032. The Compound Average Growth Rate (CAGR) over this period would be 14.6%. There is a strong market pull for OEU™.

The customer wants better energy management systems, as evidenced by the predicted market growth. However, the customer must have certain needs satisfied in order to adopt the systems. The energy management systems must be easy to install and have ease of use. The customer wants the cost of implementation to be as low as possible. A multiple vendor solution is needed so the customer is not locked to a single vendor and can install best-in-class devices throughout the system. When the customer looks at the cost of energy today, the customer sees a higher return on investment (ROI) with the application of energy management systems. Since the CIP Energy™ Initiative through the ODVA Energy Applications SIG can provide the required solution and answers the customer needs, it is time to restart both.

There is governmental and societal pressure on our customers to reduce energy usage. Many country and local governments have policies and programs to reduce GreenHouse Gases (GHG) and companies’ carbon footprints. The World Economic Forum states “With industry responsible for 30% of global CO2 emissions, industrial clusters will be a critical player in accelerating the path towards net zero”. The ideal goal is net-zero carbon emissions. All levels of society and governments are calling for a solution. We can provide that solution, together.

Evolving energy management work

There are many reasons to update or evolve the CIP Energy Initiative. But to do so, the ODVA Energy Applications SIG would need to be restarted. The SIG will need to be actively supported in ODVA by the member companies. It cannot be a one or two company effort. There is plenty of work for the CIP Energy SIG to enhance the current object specifications.

The changes made to cascading for the Power Curtailment Object will need to be reflected in Power Management Object.

The ODVA Energy Applications SIG identified additional material that needed to be included in the CIP Energy Objects. However, the SIG went into hibernation before completing this work. To incorporate the enhancements, the uncompleted work, and to collaborate with the OPC Foundation energy partnership, the member companies of ODVA need to drive this activity. The timing could not be better to focus on the Optimization of Energy Usage for all ODVA members. If the CIP Energy Initiative is going to be promoted by ODVA, the initial plan needs to be completed.

Conclusion

There is a growing movement of energy awareness in all industries. There is a strong marketing push for better optimization of energy usage in industrial automation. ODVA was ahead of its time when it introduced the CIP Energy Initiative. However, the CIP Energy Initiative has fallen behind other energy management activities.

The implementation of the CIP EnergyTM Objects in ODVA vendor products has been limited. However, the market needs to see valid and complete energy management solutions for implementation. The current CIP Energy Initiative is not complete. The ODVA Energy Objects need to be enhanced to reestablish their state-of-the-art behavior.

The mix of naming conventions for the energy and power objects can be confusing to the users of the objects. Consistent use of “Energy” in these objects would unify the message and usage of the objects. We would have five energy objects: Base Energy Object, Electrical Energy Object, Non-Electrical Energy Object, Energy Curtailment Object, and the Energy Management Object. These would be the basis for the ODVA CIP Energy Initiative.

All of the ODVA Energy Objects will need to be updated to reflect the information in the power consumption management OPC UA specification as drafted by the Power Consumption Management Group. There is plenty of work needed to update and complete the ODVA CIP Energy Initiative plan. The time is right to re-energize this effort. It will take a multi-membership effort to make the ODVA CIP Energy Initiative relevant in the market and useful to our customers.

Rick Blair, Senior Principal Network Architect; and Todd Andrew Snide, Consulting Engineer, Schneider Electric