TechnologyMay 30, 2021

Single Pair Ethernet Technology Megatrends

A coalition of industrial companies is working toward a single vision, and backing Single Pair Ethernet and the T1 interface with the goal of making SPE technology the infrastructure basis that will make the Industrial Internet of Things (IIoT) and Industry 4.0 possible.

Single Pair Ethernet is an emerging technology that describes the transmission of Ethernet over only one pair of copper wires. Along with implementing data transmission using Ethernet communications, SPE enables a simultaneous power supply of terminal devices via PoDL (Power over Data Line).

SPE is in the process of developing slim cabling/connection solutions that reduce weight, save on space and make it possible to create an infrastructure for Industrial Internet of Things applications by combining Ethernet and TCP/IP communications.

The miniaturized SPE standard interface for industrial applications, T1 Industrial style according to IEC 63171-6, has a goal of efficiently reaching every sensor and actuator in the field with slim SPE cables. The entire cabling becomes simpler, and can also be installed much faster.

In this report, IEB offers comprehensive coverage and the perspective of industry leaders, along with a picture of how SPE is moving ahead. A broad range of initiatives demonstrates the potential of the technology, and illustrates how SPE together with Industrial Ethernet can enable space-saving and cost-efficient solutions from the cloud to field-level devices.

Developing SPE ecosystem

Tools to drive industrial automation forward

TE Connectivity considers Single Pair Ethernet (SPE) the next generation Ethernet connector because it’s different from the current standards in every way. It uses different semiconductors and cables, and the connector itself is different too; it’s basically part of an entire ecosystem.

“The standards for SPE are different. For example, the traditional 40 meters shielded Ethernet T1 standard for SPE isn’t long enough to meet the distance requirements in industrial networks, and often the transmission rate is lower. But the long distance SPE standard T1L using the shielded twisted pair cable type cover 1-1.5 kilometers, far better than the traditional 4 wire and 8 wire implementations with a range of about 100 meters,” Ruud van den Brink, product manager for industrial communications at TE Connectivity, told the Industrial Ethernet Book recently.

He added that the SPE connectors are also different. For example, consider an IP20-based connector. It has two pins, a board connector and a cable connector, and supports the IEC63171-6 standard. Then there’s a M8 hybrid connector (an IP67 connector).

The four contacts are what make it a hybrid; two contacts are used for data transmission, and two are used for auxiliary power up to 400-watts. Using power over data line (PoDL) protocols would get you only one-eight of that total.

TE as a founding member of the SPE Partner Network has teamed up with many industry players pushing the IEC63171-6 standards in the SPE eco system.

Unique technology

Current industrial automation systems were built up out of different network structures, each with a different communication standard attached to it. Because the standards are different across networks, gateways are required to help “translate” those communications so machines can seamlessly exchange information. The gateways and various communications standards add delay to the communication and limit transparency.

According to van den Brink, SPE technology is designed so that all machines across the network “talk” in the same language: Ethernet. This is eliminating the need for translation between various communication standards.

SPE connectors and cables are simpler in build-up by reducing complexity and costs,; it offers a scalable (Ethernet) foundation to go beyond previous limited speed and the advantages of interoperability.

“SPE is a new standard making its way into the industrial space with obvious benefits in the industrial automation sector and in the industrial internet of things (IIoT),” he said. “Both require increasingly complex systems yet are built on an outdated legacy of multiple communication standards. At TE Connectivity, we believe SPE is essential to helping IIoT drive industrial automation forward.”

Technical benefits

SPE enables cross-network real-time communication without any loss in information so that industrial engineers can build an all Ethernet more streamlined, unified automation ecosystem that’s complements the traditional Industrial ethernet solutions.

The benefits of SPE are many, and include:

- Allowing barrier-free communication from the sensor to the cloud

- Providing movement freedom to applications

- Making miniaturization possible with power over data line (PoDL) and hybrid connector solutions (high power single wire)

- Facilitating an open ecosystem

- Allowing real-time, high-speed communication connections up to 1Gb/second and cable length up to 1,000 meters for 10Mb/second

Impact of SPE technology

“SPE helps accelerate the trend toward transparent communication from machine to machine and machine to human. This allows for real-time, high-speed and secure Ethernet communication,” van den Brink stated.

“If you look at the networks topology today, traditional ethernet (4 and 8 wire) is being used and addressed by Mini I/O, by M8, M12 or RJ45. On the factory floor—there’s far less Ethernet used, mostly due to implementations with traditional bus and serial communications. With that part of the network implemented with SPE, one transparent Ethernet based network can be built.”

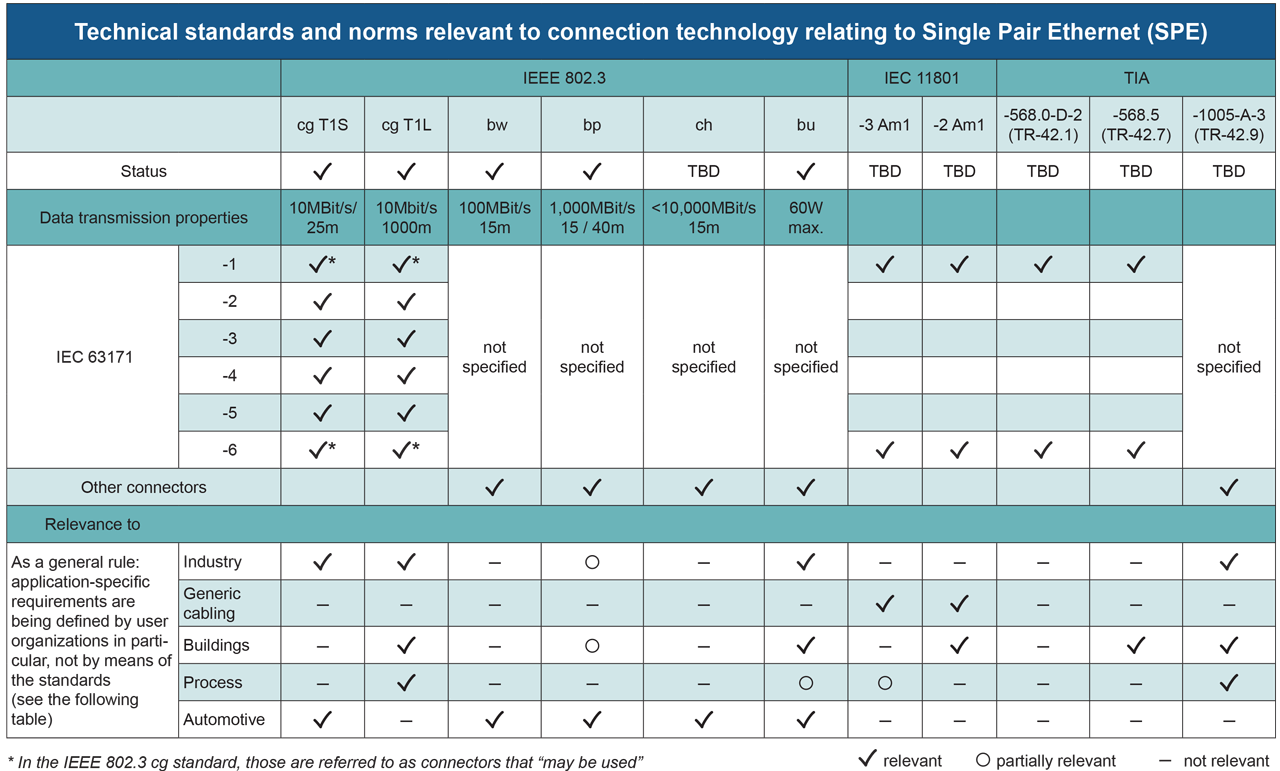

Single Pair Ethernet technical standards, connection technology.

Performance & Security

SPE forms a foundation for innovation

According to Bob Voss, Senior Principal Engineer at Panduit, SPE is the great equalizer. By enabling the entire OT network to be Ethernet and replacing legacy protocols with a universal language, SPE lays the foundation for a higher functioning, more secure network that addresses the looming business continuity risks that get a little closer each day.

“It may seem counterintuitive, but one of the biggest drivers for increased adoption of the latest SPE technologies will be the aging workforce. A lot of OT network functionality on the edge of the network is run on legacy protocols, which also poses a few big problems,” Voss said.

He added that the knowledge to operate, diagnose, troubleshoot, all the care and feeding stuff, for those aging protocols is locked inside the heads of even older engineers. Their collective retirements are creating a growing skills gap that does not really have a solution. Once this older generation decides they rather be laying on the beach with a piña colada than be on call to fix OT issues ad hoc, you are going to have a serious business continuity issue as well.

“OT networks do two important jobs: they take care of the profit-making assets of the business – machines, process skids, etc. – and occupancy safety and comfort within a building,” he concluded. “If these things start malfunctioning and can’t be fixed by onsite staff, it can put your entire operation in jeopardy.”

Single Pair Ethernet benefits

Voss said there are a number of things that the standards and developments community got right with SPE.

Technical benefits

- Extreme distance: SPE can create Ethernet links up to a kilometer in length – 10 times what I can do with 4-pair Ethernet, plus the option of supplying power

- Provides a significant speed increase – SPE replaces protocols running at 31.2kb/s with 10 Mb/s speeds

- Utilizes a simple, robust media that’s easy to field terminate

- Ability to support proven topologies like point to point and multidrop that we use in OT networks today

- Massive increase in network security – replace vulnerable older protocols with IP networking

Operational benefits

- SPE instantly adds value to the enterprise by allowing OT to become an integral part of a single-protocol, seamless network. This is a huge IoT enabler.

- IoT brings more information forward than just what’s mission critical, it provides contextual data that can optimize operations. But if all that data is on different networks, it may not be of much help.

- SPE solves this by allowing for enormous, rich data streams to be federated and accessed at the exact moment you need it to make a critical decision.

Security solutions

According to Voss, SPE isn’t cyber vulnerable, unlike some of the legacy protocols.

“Sometimes when I speak on this topic people will push back and say something to the effect of ‘I don’t care if someone breaches the edge of the network and sees something like what our kiln temperature is.’ And while that may be true, the fact is that the cyber vulnerability at the edge isn’t that third parties can see non-sensitive data, it’s that they’ll exploit these compromised areas to work their way back up the network.” Voss said.

SPE excels in this scenario because Ethernet opens the doors to the full IP security suite – VLAN, segmentation – and all the other cutting edge security that isn’t available with legacy protocols.

“I like to say that older protocols rely on ‘security through obscurity,’ a notion that if no one knows what they are looking at that they won’t tamper with it,” Voss added. “Unfortunately, cybercrime is a big business these days and taking this type of lax position to security is an enormous risk.”

Progress and overall impact

According to Voss, if we were to plot SPE on the diffusion of innovation bell-curve, it’d show that we’re still in the early adopter phase. But there is a determination to continue making progress, even if it’s one industry at a time.

“For example, we’re going to hit a big milestone this year in the processing industry with Ethernet APL – a process industry optimized instantiation of SPE and IEEE 802.3,” he said. “Given the combustible nature of petrochemical, oil and gas, and other common industry materials, getting the Ethernet-APL standard right is equal parts important and difficult.”

To that point, Ethernet-APL is the result of a collaborative effort among four different standards bodies and a “who’s who” of 12 automation manufacturers. When the initiative was announced, the goals and timing were very ambitious, with target dates in June 2021 to have APL compliant products and performance testing protocols available. The effort put into the development is paying off because, as of now, timetables are still intact, drafts have been submitted, and the standard is being widely embraced across the process industry.

Key next steps

Voss believes that adoption of SPE will gain compounding momentum as more and more use cases and case studies emerge. Automation manufacturers aren’t going to adopt new tech for the sake of new tech; they need to see the value first.

SPE provides a wide range of security and deployment benefits while solving the industry skills gap problem that continues to grow as the aging workforce enters retirement.

“Each successful deployment will embolden the next. I think the adoption cycle of BASE-T Ethernet is a great parallel to what we’re seeing with SPE,” Voss said.

“There are four billion BASE-T ports out there and at the beginning, they were only used for VoIP phones and computers. But adoption ballooned when people figured out that by adding printers to the network, they could serve jobs right from the network by just plugging in an RJ45. No more drivers, no more parallel stuff, no more dedicated computers to support the printer,” he added.

For SPE, Ethernet-APL is a great first step because it’s an effective solution designed for complex environments with life safety implications. Voss says “kudos to the control industry for embracing it. I suspect other industries will follow up with their own innovation and implementations soon after.”

Seven companies including HARTING, TE Connectivity, HIROSE, Würth Elektronik, LEONI, Murrelektronik and Softing IT Networks formed the founding members of the SPE Industrial Partner Network. Total membership has now grown to 47 companies, as they continue to work collectively on SPE technology.

Technological megatrends

New requirements for future connectivity

During this year’s 2021 HANNOVER MESSE, HARTING’s technology group reaffirmed its focus on answers to the three global societal megatrends of sustainability, demographic change and (de-) globalisation. These societal megatrends are closely intertwined with the technological megatrends of autonomy, the digital twin and modularisation.

“These trends are going hand in hand with new, comprehensive requirements for the connectivity of the future,” explained Dr.-Ing. Kurt D. Bettenhausen, Director of “New Technologies and Development” at HARTING. “Under the term of Connectivity+, we are grouping forward-looking topics such as DC power supply in industry, electromobility and new industrial ecosystems such as Single Pair Ethernet (SPE). With these and other topics, we will be playing a trend-setting role in shaping a powerful infrastructure for the digitalisation of industry,” Bettenhausen said.

Transformation & digitalisation

Today, Ethernet is already the predominant communication medium in industrial automation and will penetrate into the last areas of the automation pyramid in the future. HARTING is creating the appropriate infrastructure for these developments.

“Industrial transformation needs digitalisation”, Ralf Klein, Managing Director of HARTING Electronics explained. The aim is to be able to offer customers a reliable, miniaturised and resource-saving infrastructure from the cloud down to every individual sensor.

In this way, HARTING is actively supporting industry’s path to the IIoT. However, innovative answers in terms of size, modularity and standardisation of components alone will not be enough, which is why HARTING, since 2017, has been focusing on the development of the entire single pair Ethernet ecosystem in the development, standardisation and portfolio structure of the T1 industrial interface in accordance with IEC 63171-6. Only with all the necessary components and strong partners accompanying the new physical layer SPE will it be possible to realise the technological basis in the form of single-pair copper cabling extending to the field level.

In the meantime, as part of the SPE Industrial Partner Network e.V., HARTING is driving this complete ecosystem forward together with 47 other market leaders. “Setting standards together with partners is an important point for the sustainability and success of a solution. The SPE network is the leading global network,” as Ralf Klein emphasized.

Expanding SPE portfolios

Innovations for industrial communication

Single Pair Ethernet (SPE) is a key technology on the way to the SmartFactory and Industry 4.0. It enables more consistent and more economical Industrial Ethernet networks and only requires one pair of wires to transfer data. So far, 2- and 4-pair Ethernet cables have been the standard.

These savings mean that new smart components can be integrated into networks that were previously not networked via Industrial Ethernet. With its ETHERLINE T1 product family, LAPP says it has developed prototypes of single pair Ethernet cables for use in industrial machines and systems at a very early stage.

Its first single pair Ethernet cable is now available from stock. In its spring launch, LAPP presented the new ETHERLINE T1 Y Flex 1x2x22/7 AWG.

“Single Pair Ethernet is an important technology for the future. For broad market penetration, however, we need standardized and uniform connectors,” stated Christian Illenseer, Product Manager Industrial Communication at LAPP.

“You only need one standard to ensure the compatibility of the components. We chose the SPE Industrial Partner Network because we are of the opinion that this standard has the greatest chance of success in the market. ”

Product innovations

The new ETHERLINE T1 Y Flex 1x2x22 / 7 AWG is a UL-certified, two-wire data line for the fast exchange of information with consistently high data rates and a significantly reduced structure. Thanks to a small bending radii and small outer diameter, it is particularly weight and space-saving, as well as being easy to lay and indispensable for connecting to the field level.

A new Power-over-Data-Line-capable cable, according to IEEE 802.3bu, has been specially designed for the transmission of digital signals in the frequency range up to 600 MHz and up to 40 m away. It enables the simultaneous power and data supply of SPE end devices with low energy requirements (up to 50 W).

The structure of the SPE line guarantees ideal protection against electromagnetic interference: thanks to an aluminum-clad foil and a copper braid shield with a high degree of coverage (SF / UTP), it is double-shielded. In addition, the PVC outer jacket is resistant to acids and alkalis and is conditionally oil-resistant. The UL / CSA certification allows the product to be used in North America. As a UL-listed Power Limited Tray Cable (PLTC), the new Single Pair Ethernet cable can also be laid openly on cable racks.

The new ETHERLINE T1 Y Flex 1x2x22 / 7 AWG product offers versatile, future-proof application options in automation technology. The world market leader for integrated solutions in the field of cable and connection technology has defined a wide range of applications:

- Flexible use in dry and damp rooms, as well as for medium mechanical stress,

- Structured cabling according to DIN EN 50173 and ISO / IEC 11801,

- Single-pair Ethernet applications 1000Base-T1 according to IEEE 802.3bp and 100Base-T1 (IEEE 802.3bw).

According to Lapp, the IEEE 802.3 bp standard describes a physical layer that allows 1 Gbit / s over single-pair twisted-pair copper cables over a distance of 40 m with shielded lines or 15 m with unshielded lines.

“Possible applications in production automation would be the connection of gigabit communication participants within the control cabinet or sensors with high data rates, such as high-resolution image processing systems.

The IEEE 802.3 bw standard enables the same cable lengths, however, for 100 Mbit/s. This technology should be of interest for connecting devices in the control cabinet, especially because of the reduced distance,” the company stated.

In-cabinet solution & Ethernet-APL

Device-level and process automation solutions

Two areas of focus for ODVA and its members focus on in-cabinet, resource-constrained device support for devices such as contactors and push buttons, along with the development of SPE solution to enable long reach and hazardous area capable Ethernet within process automation.

In-cabinet device support

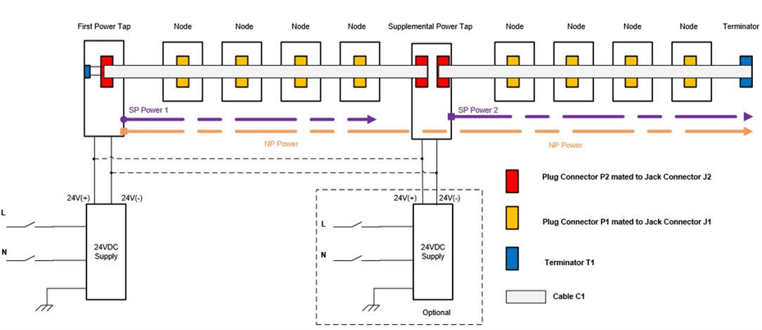

EtherNet/IP In-Cabinet Resource-Constrained Multidrop Flat Cable Illustration.

EtherNet/IP In-Cabinet Resource-Constrained Multidrop Flat Cable Illustration.

The recently released EtherNet/IP Specification enhancement that enables in-cabinet resource-constrained device support is a significant technological advancement that utilizes Single Pair Ethernet (IEEE Std 802.3cg-2019 10BASE-T1S) to bring Ethernet to low-level in-cabinet devices such as contactors and push buttons.

Limitations including cost, available space, and power consumption have resulted in many edge devices remaining hardwired. However, a lack of network connectivity results in time consuming installation, challenging troubleshooting, and a deficiency of diagnostic information.

The steady decline in the cost and size of semiconductor chips combined with the availability of Single Pair Ethernet has enabled a new EtherNet/IP in cabinet bus solution that uses a multi-drop network and control power cable that spans a single cabinet with one interface per device and one switch port across multiple devices to reduce both commissioning and hardware cost.

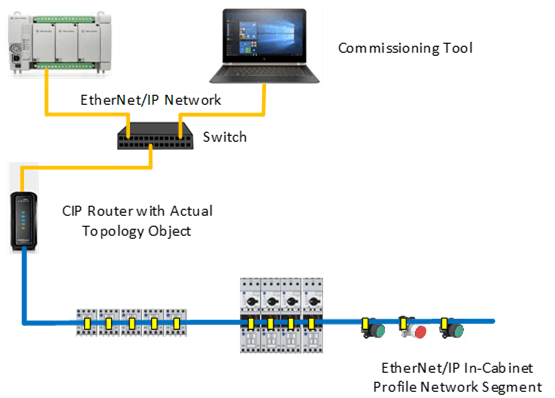

EtherNet/IP In-Cabinet Profile Network Segment With Actual Topology Object in Router.

UDP-only communication

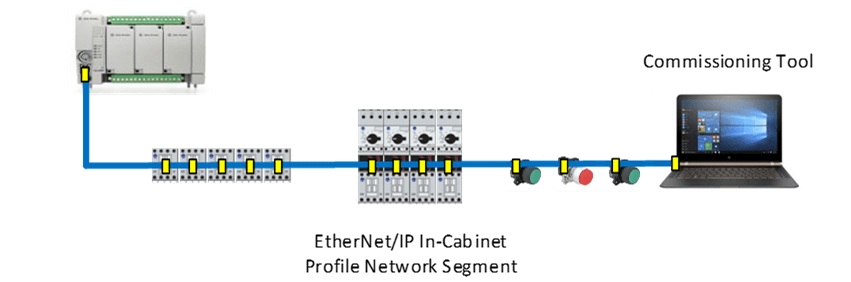

The inclusion of resource-constrained devices within cabinets on an EtherNet/IP network is made possible by low overhead UDP-only communication, a LLDP node topology discovery mechanism, auto-commissioning support, and auto-device replacement support. A new select line circuit facilitates the efficient delivery of system wide sequential commands, eliminates configuration switches by enabling topology discovery based on relative position, and allows for direct connection with programming tools during assembly for parameterization.

According to Dr. Al Beydoun, President and Executive Director of ODVA, “EtherNet/IP for in-cabinet resource-constrained devices will enable the benefits of additional diagnostics, asset information and parameterization capability, automatic node topology discovery, and plug and play device replacement compared to existing hard-wired devices.”

“Single Pair Ethernet will enable the use of one seamless CIP network for both constrained and non-constrained devices. UDP-only EtherNet/IP communication and shared in-cabinet external power and communication cabling were designed to help increase installation return on investment,” he added.

The EtherNet/IP specification for in-cabinet resource-constrained devices was released in April 2021 by ODVA. Expanding the connectivity of EtherNet/IP to include devices with the smallest physical footprint and most limited hardware resources opens up tremendous opportunity for further digital transformation within automation at the edge. The ability to obtain diagnostic, prognostic, and asset identity information remotely from more devices will drive down incidents of unplanned downtime and improve the efficiency of existing assets. The connection of resource-constrained devices to EtherNet/IP increases the value of existing networks for end users and reduces the need for secondary lower-level networks.

Select Line for EtherNet/IP In-Cabinet Resource-Constrained Bus System.

Ethernet-APL

Additionally, the pending Ethernet-APL technology launch that is slated for 2021 will utilize a form of Single Pair Ethernet that has been optimized for the process industries to enable long reach and hazardous area capable Ethernet within process automation.

ODVA is actively engaged with leading standards development organizations and industry members to develop the technology, guidelines, and best practices to promote adoption of and to ensure successful deployment of Ethernet-APL to the field. Ethernet-APL will soon open up process operations to the higher speed and rich data afforded via industrial Ethernet based networks such as EtherNet/IP.

Ethernet-APL is more than just Single Pair Ethernet. Ethernet-APL is made up of Single Pair Ethernet (IEEE 802.3cg-2019, 10BASE-T1L), 2-Wire Intrinsically Safe Ethernet (IEC 60079, 2-WISE), and Type A fieldbus cable (IEC 61158-2, for intrinsic safety). The combination of Single Pair Ethernet, Intrinsic Safety, and Type A fieldbus cable is what allows Ethernet-APL to satisfy the process industry needs for long reach cabling of up to 1,000 meters per trunk length and intrinsic safety protection for all hazardous Zones and Divisions. 2-WISE defines intrinsic safety protection, including simple steps for verification of intrinsic safety without calculations.

Beydoun said that the Ethernet-APL cable specification is important because end users can potentially re-use existing installed Type A fieldbus cable that meets the resistance standards of 100 ohms with +/- 20 ohms tolerance. Type A two-wire cable with shielding is polarity independent to reduce installation errors and only requires a screwdriver to ensure connectivity along with related wire preparation tools to physical connect to the remaining automation installation.

This can potentially result in a much easier migration for existing fieldbus installations that could net significant amounts of time and money savings for large installations and long cable runs.

Impact of new technologies

“Ethernet-APL will use Single Pair Ethernet Technology to help move critical information from the device to the cloud for future applications with modern IIoT and Industry 4.0 solutions,” Beydoun said. “Interest in Ethernet-APL from end users has been enthusiastic and will help drive adoption of Ethernet-APL, which will enable companies to gain the benefits of valuable additional data insights that will help drive cost savings.”

“EtherNet/IP will be one of the key available industrial Ethernet communication networks that will run on Ethernet-APL as EtherNet/IP was originally designed for the future with a basis in IP technology and has been named as one of the minimum binding requirements for field level to higher system level communication by NAMUR,” he added.

Expanding SPE portfolio

Innovations for industrial communication

According to HELUKABEL, the key to Single Pair Ethernet technology is centered on its ability to make it possible to operate Ethernet communication with just one pair.

“This saves space and weight and, especially in times of extremely high raw material costs, this is a resource-saving option for transmitting Ethernet,” the company stated in response to a series of questions from IEB. “But also applications that for reasons of cost or analog technology like sensors … is opened up with new possibilities by using SPE.”

“Classic Ethernet cables are using 2- or 4 paired cables which are physical bigger than a single-pair-Ethernet cable. Of course, SPE cannot cover all the advantages of classic Ethernet cabling, but there are clear advantages for some areas. SPE offers undeniable advantages wherever there is little space requirement or where you have to pay attention to low weight.”

The company noted that SPE is currently only used in automobiles. But in automation technology, and also in process automation, the indisputable advantages of the new technology have been recognized. At the moment there are not all components in series for these areas, but the members of the SPE Industrial Partner Network (www.single-pair-ethernet.com) are working on them.

Currently, there are three cable versions available from HELUKABEL in stock:

- Two drag chain cables for 1 Gbit up to 40m in AWG 26 and AWG 22 and;

- One process automation cable in AWG 18 for fixed installation for 10 Mbit up to 1000m

“Since this technology is still in its infancy, other variants will follow, but this will only emerge over time. For us, one thing is certain: In the future, single pair Ethernet will have its place in industrial and process automation like the ‘amen’ in church,” they concluded.