TechnologyJuly 20, 2023

Ethernet of the future with TSN: connectivity on a new level

Thomas Rodenbusch-Mohr, Product Cluster Manager at Hirschmann Automation and Control GmbH, a subsidiary of the Belden Group and member company of the CC-Link Partner Association (CLPA), explains the advantages of TSN and why Hirschmann is offering TSN-enabled products.

Time-Sensitive Networking is paving the way for decisive advances in industrial networking, because the functionality of TSN makes Ethernet future-proof for next generation applications. The key benefit is the enablement of open, unified and convergent architectures that hold enormous potential for productivity gains. So it is only logical that compatible, certified network switches are already being offered. But in order to take full advantage of TSN, both the end components and infrastructure must support this technology.

Converged networks

Convergence is without question a key aspect of future-oriented smart applications in a variety of sectors, from manufacturing to transportation to energy automation. TSN creates the appropriate conditions by enabling highly deterministic communication within the vendor-neutral standard Ethernet.

TSN can differentiate between data classes and assign priority levels to the individual data packets. This is how network traffic flows, taking into account the timings for each class. As a result, TSN can even meet the demanding real-time communication requirements of industrial automation applications.

In particular, TSN is able to support the integration of Information Technology (IT) and Operational Technology (OT). “This innovation promotes network convergence because it can send IT and OT traffic over the same wire and still meet the different needs within the communication. An important advantage of TSN for industrial applications is therefore the standardization of networks that previously had to be kept separate. This results in a reduction in complexity in the networks and savings in investment costs. Above all, however, the extensive technical advances made possible by TSN open network architectures. This opens up a veritable treasure trove of information that data scientists can use to transform Industry 4. 0 and smart applications. If this data can be used seamlessly directly from the source, we no longer need gateways in between.

Another TSN feature that is valuable for users, automation engineers and machine builders is upwards and downwards compatibility, which means that existing and future Ethernet components can be integrated into TSN-capable networks with corresponding, complete migration paths. In addition, the new TSN mechanisms are an addition to the Ethernet toolbox and thus offer the same flexibility in network architecture and bandwidth scaling as traditional Ethernet.

Connected industries of the future

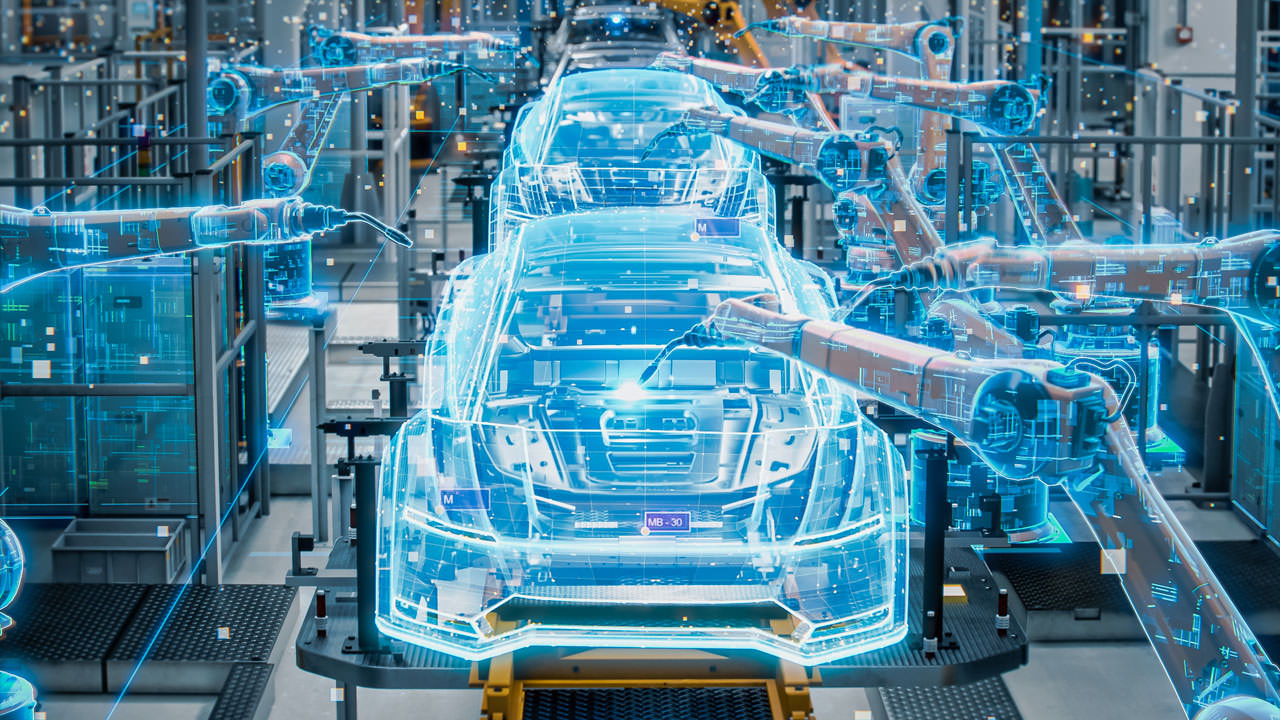

These competitive advantages are the basis for cost-efficient, future-oriented networks. Probably no other area benefits from the TSN technology and the associated advances to the same extent as factory and process automation.

For example, critical data traffic, such as motion control data with its precise real-time requirements, and non-time-critical data traffic, such as bandwidth-intensive file transfers, can be handled simultaneously over a network without conflicts arising.

Ultimately, network convergence enables decentralized, real-time control. This allows large numbers of complex machines and robots to interact with each other more precisely and flexibly than was previously possible. In addition, companies can make better use of important applications, such as predictive maintenance, that require the analysis of large amounts of sensor data. Open and converged networks from the cloud to the sensors on the shop floor also provide secure access for performing maintenance work and other tasks remotely.

Furthermore, TSN offers high-precision time synchronization (IEEE 802.1AS) and mechanisms for controlling bandwidth usage (IEEE 802.1Qbv). These capabilities are of great value in both discrete manufacturing and process automation networks because they provide an accurate time reference for sequencing-based applications.

Take the chance early

Belden and its subsidiary Hirschmann relied on TSN at an early stage in order to make their products and their customers’ systems future-proof: “Belden has always been a technology pioneer and, with this intention, was also one of the initiators of the standardization of TSN at the IEEE in the early 2010s . Belden’s robust portfolio includes market-leading industrial networking solutions for the most demanding environments and is based on standard Ethernet, making TSN an excellent fit.”

When developing its first TSN-compatible products, the RSPE and BOBCAT managed DIN rail switches, Belden chose as the underlying technology CC-Link IE TSN, the first open industrial Gigabit Ethernet with TSN functionality. The fact that the CLPA offered the first industrial TSN profile for certification was of course a decisive factor in our decision. The company also knew how to use the new TSN tools for Ethernet and chose the appropriate mechanisms for well-functioning data communication with a vendor-neutral network technology.