ApplicationsJuly 27, 2019

Palm oil tank farms ready for digitalization

Direct integration of Profibus PA field level into Ethernet control systems has created transparency and consistency for a provider of palm oil tank farms. An integrated platform handles reporting and offers real-time transparency for total inventory management of both raw materials and finished goods.

Giant tank farms are not only just in the oil and gas industry. More and more extensive tank farms are coming into existence with the flourishing palm oil industry in Southeast Asia. In Indonesia, a new project has been implemented by the system integrator DNR Process Solutions which uses its tank farm management system. DNR chose to directly integrate the Profibus PA segments via Ethernet pnGate PA gateways from Softing when it came to selecting an installation that would be up to Industry 4.0.

Large tank farms

Refined palm oil is stored on site in large tank farms, comprising many large tanks, before being transported via ship or tankers for further processing. One of the world’s leading palm oil producers in Indonesia works extremely efficiently and with high productivity thanks to the plant’s high degree of automation, which also includes the downstream processes.

In particular, DNR Process Solutions strives for seamless and effective integration of the sensor and actuator technology into the higher-level control system architecture, and extending to the management level within one tank farm.

This allows integrated inventory management and monitoring of field devices that facilitates maintenance scheduling and offers the possibility for remote monitoring to create an IIOT solution.

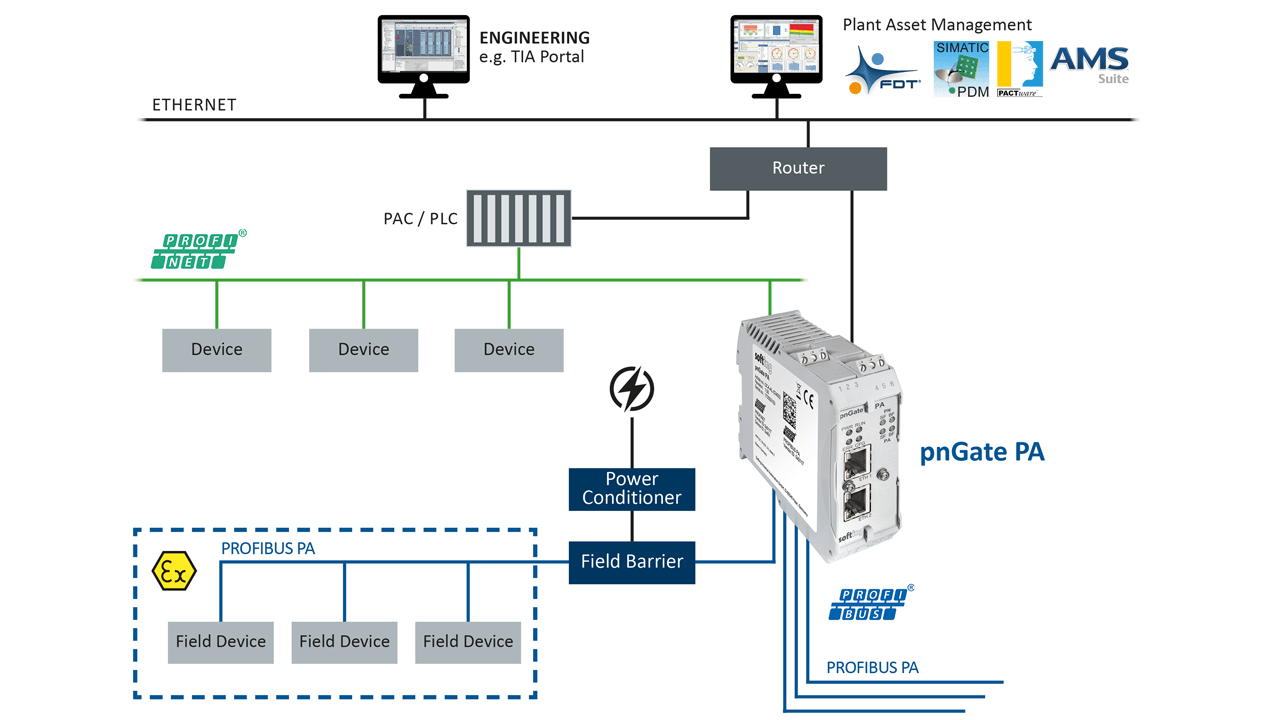

Users who want to combine the advantages of Industrial Ethernet with consistent data transmission in process automation, can use pnGate PA to make the DP level superfluous.

International standards

In their search for an extensive integration solution, the palm oil producer’s automation specialists turned to DNR Process Solutions. DNR offers complete solutions for integrated plant automation with an extended focus on operation of the tank farms including inventory management and materials management. With its tank farm management system, POIMS, DNR provides an extremely comprehensive tool, based on international standards and an ability to implement state-of-the-art technology.

The intelligent solution covers the special requirements of tank farms particularly well. It offers real-time transparency and can serve as an integration platform for an integrated supply chain management in bulk industries.

The POIMS inventory management forms an important part of the MES level in the system architecture of the palm oil tank farm. In the future, POIMS will provide on-site operators and management with ongoing up-to-date inventory via a firewall and remote access. This will enable more informed supply chain management decisions to be made. In addition, the data will also be used to control the loading process and invoice the delivery quantities. This information rises and falls according to the exact data coming from the field level, which must be up-to-date and available at all times.

Instrumentation over Profibus PA

The vessels in the tank farm, which consists of six groups of six tanks each, are each instrumented with a radar level gauge, a level limit switch and a multipoint thermometer. By using the reference temperature, the current volume of the stored oil quantity can be determined from the current level. Temperatures and levels are transmitted via Profibus PA.

Usually these are transmitted to the higher-level process control (Siemens S7-1500) with the aid of a DP/PA coupler, and converted to a Profinet signal which is a relatively expensive undertaking. Applications based on Profibus DP do not fully meet the high requirements of digitalization: for example, in regard to suitability in a Zone 1 area, robustness and reliability, as well as ease of use.

Digitalization solution

In mid-2018, DNR turned to its component supplier Link Vue Systems in search of an alternative for further digitalization and Industry 4.0 customization. “We wanted to find the best and most up-to-date data communication technology for our customer,” said Prafullit Sharma, Chief Technology Officer of DNR.

Transmission consistency needed to be ensured via standardized interfaces in the future. The close business relationships between Link Vue and DNR, which have existed for more than 15 years, benefited both of them. In fact, Vidyut Gandhi of Link Vue had a suggestion on how to switch to future-proof technology.

“With the relatively new pnGate PA gateway, Profibus PA segments can be directly integrated into Profinet systems,” said Gandhi. These gateways eliminate the DP level and integrate it directly on Ethernet instead. Softing also offers two versions: a 2-channel version which allows 32 PA devices to be connected, and the 4-channel version which will even connect 64 PA devices – a big contribution to cost savings when automating large areas holding 36 tanks. Normally, PN/PA gateways offered by competitors are designed for considerably fewer PA devices.

Profinet as primary network

“The main reason for choosing pnGate PA was that it allowed us to create a seamlessly integrated solution,” said Sharma. In addition, the system integrator had to take into account the need for integrating not only the PA devices, but also the conventionally wired level switches, pumps and agitators. Their I/O cards were based on the Siemens ET200 SP Profinet I/O modules. Sharma said: “That’s why it was imperative to implement Profinet as the main network.”

Since DNR had extensive experience with Profibus, including one of the world’s largest Profibus projects with around 10,000 nodes, the integration hurdles were negligible. There was one small challenge when integrating the Siemens 1500 PLC but DNR mastered it with Softing’s support.

One of the main focuses during the development of the Softing gateway was to make commissioning as easy as possible for the user. The configuration existing on the PA side can be transferred almost intuitively to the control project with the help of a special Softing web server.

The big advantage in this application for the operator is that the gateway is transparent to the operation of the system. The PA devices continue to be “visible” and the operator can assign respective process and diagnostic data to each of them and access them. Ultimately, DNR was able to complete the implementation for all of the tanks.

Real time transparency

“The integrated and unified architecture that we were able to achieve with pnGate PA is the most important benefit for the tank farm operator,” Sharma explained. It is a perfect foundation for the DNR system POIMS.

The tank farm inventory management system reliably receives up-to-date data from the field devices and in a very short period of time – a great advantage considering the vast size of the palm oil producer tank farms and all of their numerous field devices.

POIMS can provide the necessary real-time transparency for a total inventory management of both raw materials and finished goods. The integrated platform also handles reporting to improve management effectiveness. All in all, DNR can offer the palm oil producer the conditions needed for extensive digitalization of its processes and create the prerequisites for Industry 4.0.